Ultra-thin carbon-based composite panel and preparation method

A panel and carbon-based technology, which is applied in the field of preparation of ultra-thin C/C-Mo composite panels, can solve the problems of inability to make net shape, and achieve the effects of avoiding peeling and delamination, small thermal expansion coefficient, and firm and reliable combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

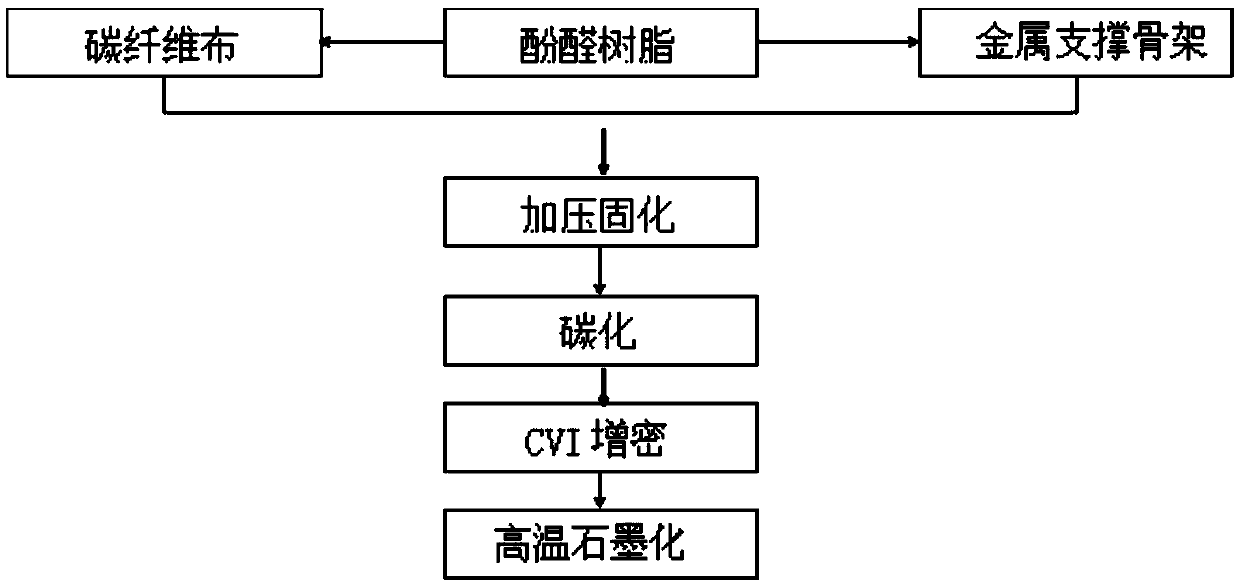

Method used

Image

Examples

Embodiment 1

[0038] (1) Cut 2 layers of molybdenum wire mesh (the parameters of molybdenum wire mesh used are: wire diameter 0.05mm, thickness 0.1mm) and 3 layers of plain weave T700 carbon fiber cloth (the parameters of used carbon cloth are: 3K, thickness 0.26mm) cut into 220× 220mm size, evenly brush the phenolic resin on the carbon cloth and the molybdenum wire mesh, lay them up alternately, and put them into the mold;

[0039] (2) Put the mold into the press, pressurize and cure, the curing temperature is 120°C, the curing time is 60min, and the control pressure is 10Mpa; after the resin is cured, the mold is pressurized and lowered to normal temperature to obtain a carbon-based panel prefabricated body;

[0040] (3) Put the carbon-based panel prefabricated body into a vacuum annealing furnace for carbonization. The carbonization process parameter is to raise the temperature from room temperature to 300°C at a heating rate of 5°C / min. After holding for 30 minutes, continue to heat up t...

Embodiment 2

[0045] (1) Cut 2 layers of molybdenum wire mesh (the parameters of molybdenum wire mesh used are: wire diameter 0.05mm, thickness 0.1mm) and 3 layers of plain weave T700 carbon fiber cloth (the parameters of used carbon cloth are: 1K, thickness 0.16mm) cut into 220× 220mm size, evenly brush the phenolic resin on the carbon cloth and the molybdenum wire mesh, lay them up alternately, and put them into the mold.

[0046] (2) Put the mold into the press, pressurize and cure, the curing temperature is 120°C, the curing time is 60min, and the control pressure is 10Mpa; after the resin is cured, the mold is pressurized and lowered to room temperature to obtain a carbon-based panel prefabricated body.

[0047] (3) Put the carbon-based panel prefabricated body into a vacuum annealing furnace for carbonization. The carbonization process parameter is to raise the temperature from room temperature to 300°C at a heating rate of 5°C / min. After holding for 30 minutes, continue to heat up to ...

Embodiment 3

[0052] (1) Cut 3 layers of molybdenum wire mesh (the parameters of molybdenum wire mesh used are: wire diameter 0.05mm, thickness 0.1mm) and 4 layers of plain weave T700 carbon fiber cloth (the parameters of used carbon cloth are: 1K, thickness 0.16mm) cut into 220× 220mm size, evenly brush the phenolic resin on the carbon cloth and the molybdenum wire mesh, lay them up alternately, and put them into the mold.

[0053] (2) Put the mold into the press, pressurize and cure, the curing temperature is 120°C, the curing time is 60min, and the control pressure is 10Mpa; after the resin is cured, the mold is pressurized and lowered to room temperature to obtain a carbon-based panel prefabricated body.

[0054] (3) Put the carbon-based panel prefabricated body into a vacuum annealing furnace for carbonization. The carbonization process parameter is to raise the temperature from room temperature to 300°C at a heating rate of 5°C / min. After holding for 30 minutes, continue to heat up to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com