Titanium-based TiNx/IrO2-Ta2O5 nanometer coating anode

A iro2-ta2o5, nano-coating technology, applied in the coating, metal material coating process, electrodes, etc., can solve the problems of low service life, harsh anode requirements, easy dissolution or passivation of anode materials, etc. Effects of prolongation, improvement of electrocatalytic activity and lifetime, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

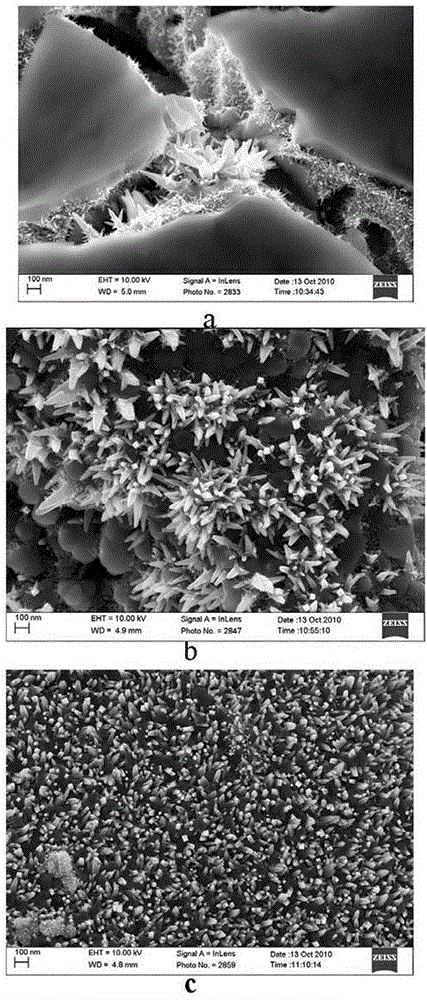

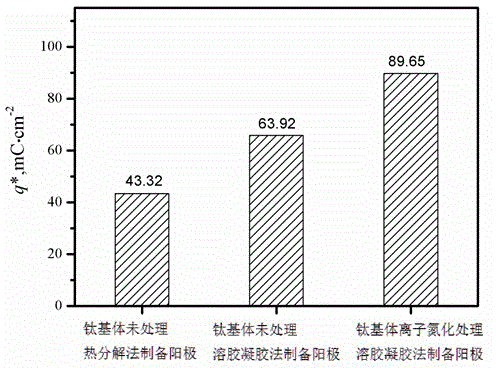

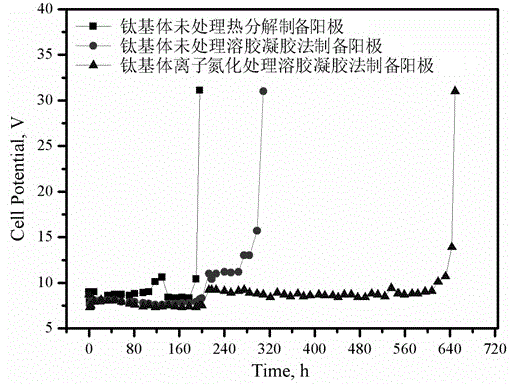

[0034] The titanium base TiNx / IrO provided by this embodiment 2 -Ta 2 o 5 Nanocoated anode consisting of a Ti base on the inside, a TiNx interlayer in the middle, and IrO on the outside 2 -Ta 2 o 5 nano coating;

[0035] The TiNx intermediate layer is prepared by subjecting the titanium base to ion nitriding treatment;

[0036] The IrO 2 -Ta 2 o 5 The nano-coating is prepared by the sol-gel method;

[0037] The base body adopts TA2 titanium.

[0038] The titanium-based TiNx / IrO 2 -Ta 2 o 5 Nano-coated anode, the molar ratio of Ir to Ta is 7:6, IrO 2 -Ta 2 o 5 Nanocoating consists of 10 layers.

[0039] The titanium-based TiNx / IrO 2 -Ta 2 o 5 Nano-coated anode, the thickness of the TiNx intermediate layer is not less than 200μm.

[0040] The titanium-based TiNx / IrO 2 -Ta 2 o 5 The preparation method of nano-coating anode specifically comprises the following steps:

[0041] (1) Substrate treatment, the titanium substrate is subjected to sandblasting treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com