Method for preparing ethylene through disproportionation of propylene

A technology for ethylene and propylene, applied in the field of propylene disproportionation to prepare ethylene, can solve the problems of single product structure, inflexible disproportionation technology, failure to produce ethylene, etc., and achieve the effects of slowing down the coking process, prolonging stability, and suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

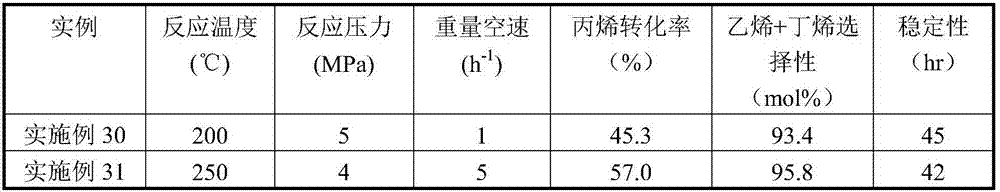

Examples

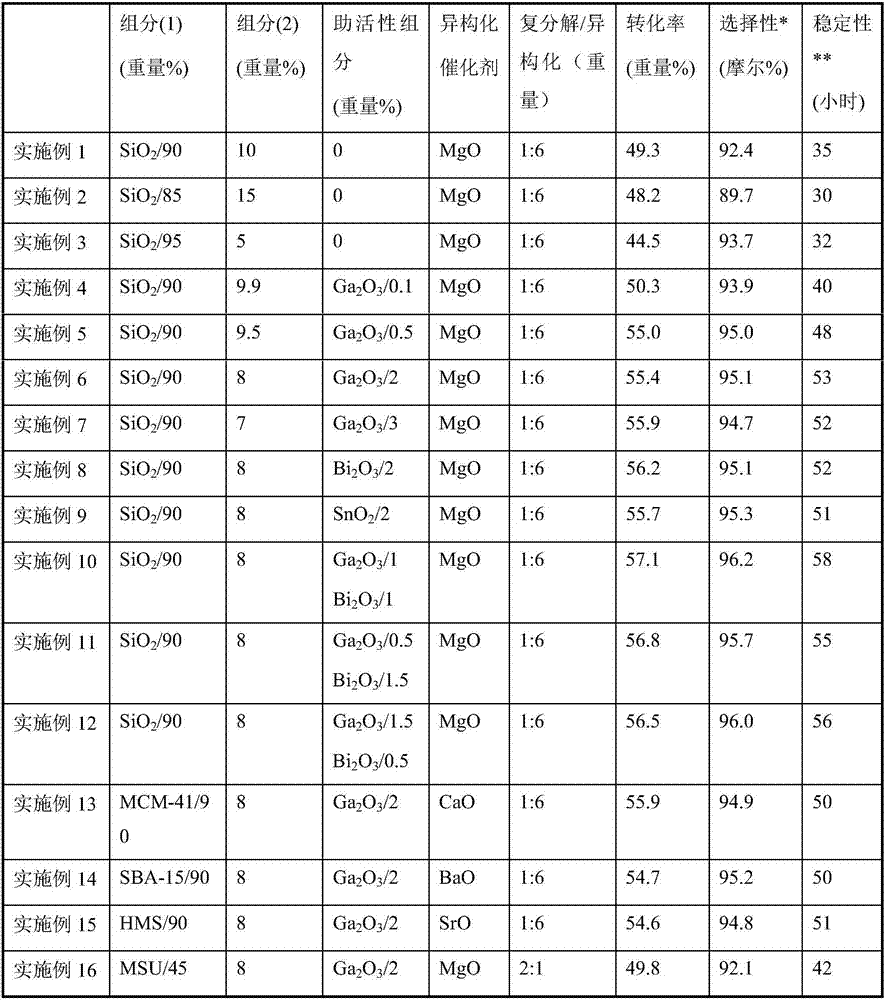

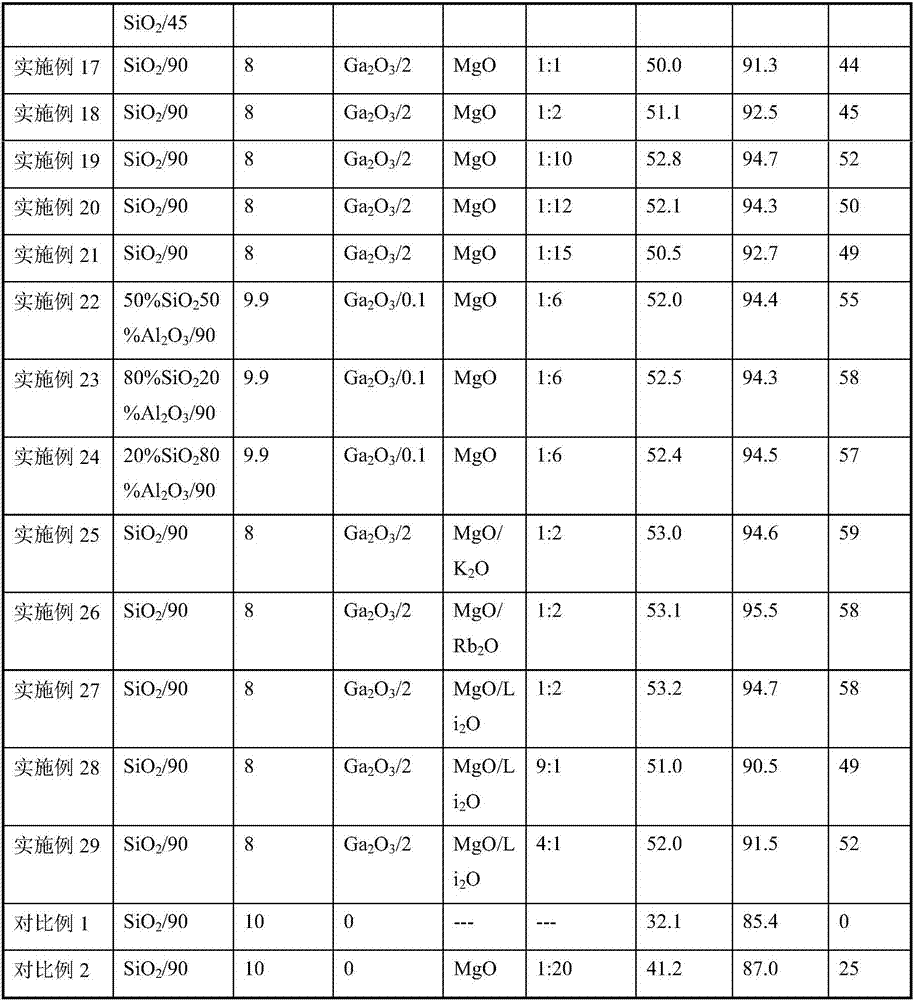

Embodiment 1

[0044] Weigh 50 grams of commercial MgO, add 500 grams of deionized water, heat and stir in a water bath at 90°C for 2 hours, filter the water in the solution with suction, dry the product at 80°C for 15 hours, and roast at 450°C for 8 hours to obtain the finished isomerization catalyst .

[0045] will load tungsten oxide 10% SiO 2 Roast at 450°C for 8 hours, mix with isomerization catalyst at 1:6 (mass ratio), install in a Φ25mm fixed bed reactor, use propylene as raw material, and use propylene at a weight space velocity of 10 hours -1 , the reaction temperature was 300°C, and the reaction pressure was 3MPa to evaluate the performance of the catalyst. The results are shown in Table 1.

Embodiment 2

[0047] Weigh 50 grams of commercial MgO, add 500 grams of deionized water, heat and stir in a water bath at 90°C for 2 hours, filter the water in the solution with suction, dry the product at 80°C for 15 hours, and roast at 450°C for 8 hours to obtain the finished isomerization catalyst .

[0048] will load tungsten oxide 15% SiO 2 Roast at 450°C for 8 hours, mix with isomerization catalyst at 1:6 (mass ratio), install in a Φ25mm fixed bed reactor, use propylene as raw material, and use propylene at a weight space velocity of 10 hours -1 , the reaction temperature was 300°C, and the reaction pressure was 3MPa to evaluate the performance of the catalyst. The results are shown in Table 1.

Embodiment 3

[0050] Weigh 50 grams of commercial MgO, add 500 grams of deionized water, heat and stir in a water bath at 90°C for 2 hours, filter the water in the solution with suction, dry the product at 80°C for 15 hours, and roast at 450°C for 8 hours to obtain the finished isomerization catalyst .

[0051] The loaded tungsten oxide 5% SiO 2 Roast at 450°C for 8 hours, mix with isomerization catalyst at 1:6 (mass ratio), install in a Φ25mm fixed bed reactor, use propylene as raw material, and use propylene at a weight space velocity of 10 hours -1 , the reaction temperature was 300°C, and the reaction pressure was 3MPa to evaluate the performance of the catalyst. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com