Drainage gas recovery method and device of air-lift combination of foam and plunger

A technology for drainage and gas production and plunger, which is applied to the valve device of wellbore/well, the components of pumping device for elastic fluid, and the production of fluid, etc. In order to reduce the gas channeling, narrow the gap, and improve the recovery factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples, and the given examples are only to illustrate the present invention, rather than to limit the scope of the present invention.

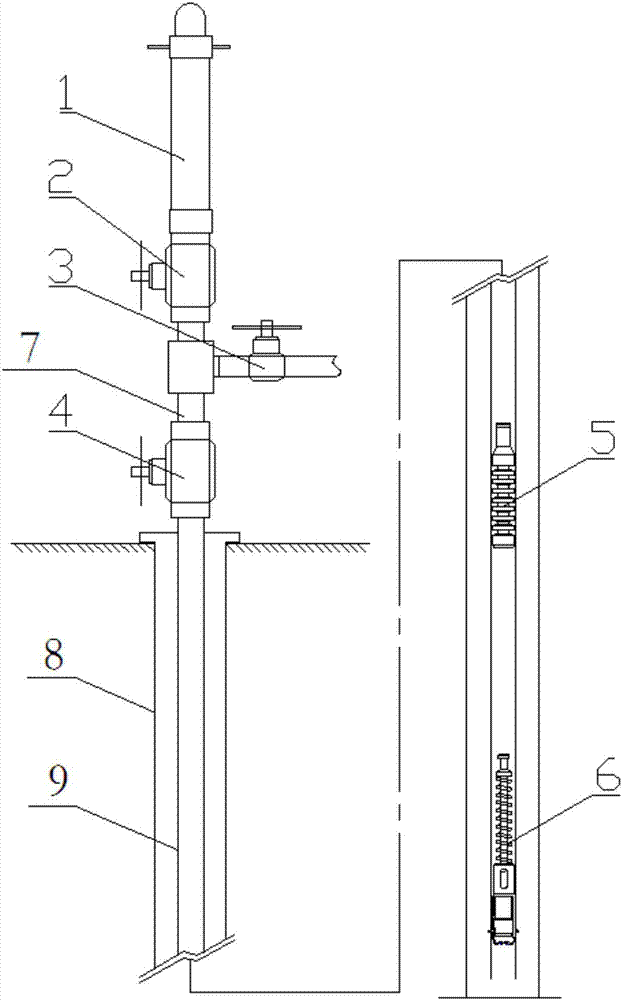

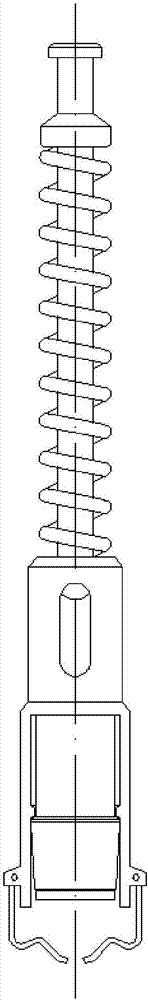

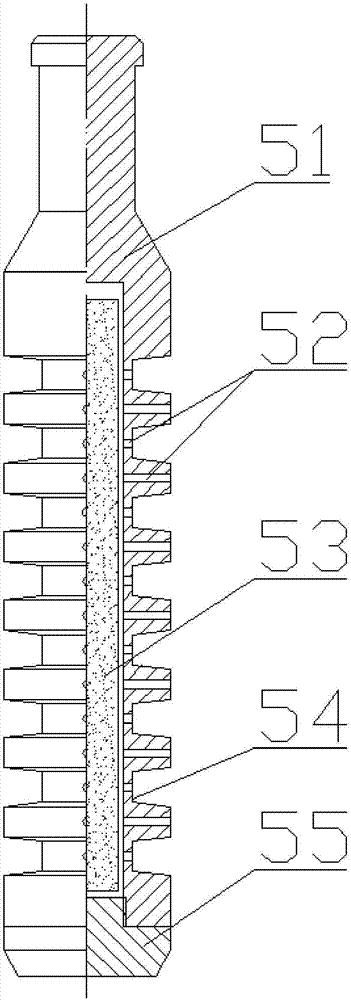

[0027] refer to Figure 1 to Figure 5 The foam and plunger gas lift combined drainage and gas production device of the present invention is composed of a blowout preventer 1 , a first gate valve 2 , a ball valve 3 , a second gate valve 4 , a plunger 5 and a seating buffer 6 . The plunger 5 is embedded with a solid foam discharge rod, and the plunger 5 is composed of a plunger body 51 , a channel 52 , a solid foam discharge rod 53 , a turbulent flow sealing groove 54 , and a base 55 .

[0028] The blowout preventer 1, the first gate valve 2, and the second gate valve 4 are connected in sequence and then connected to the oil pipe. A gas tree 7 is connected between the first gate valve 2 and the second gate valve 4. The ball valve 3 is installed on the gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com