Timing sequence optimization method for gas consumption equipment of steel enterprises

A technology that consumes equipment and optimizes methods. It is applied in electrical program control, program control, and comprehensive factory control. It can solve problems such as affecting the normal production of iron and steel enterprises, increasing the difficulty of model solving, and having many genetic dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

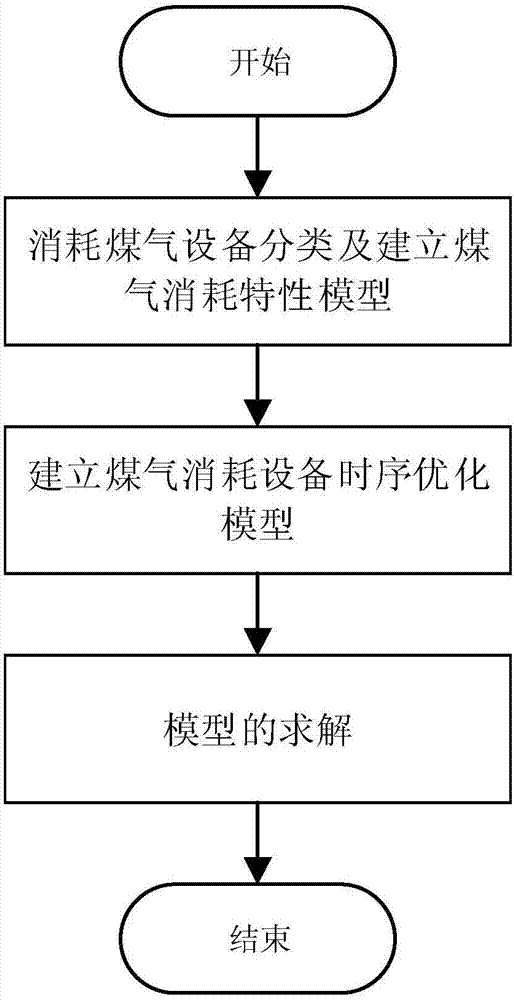

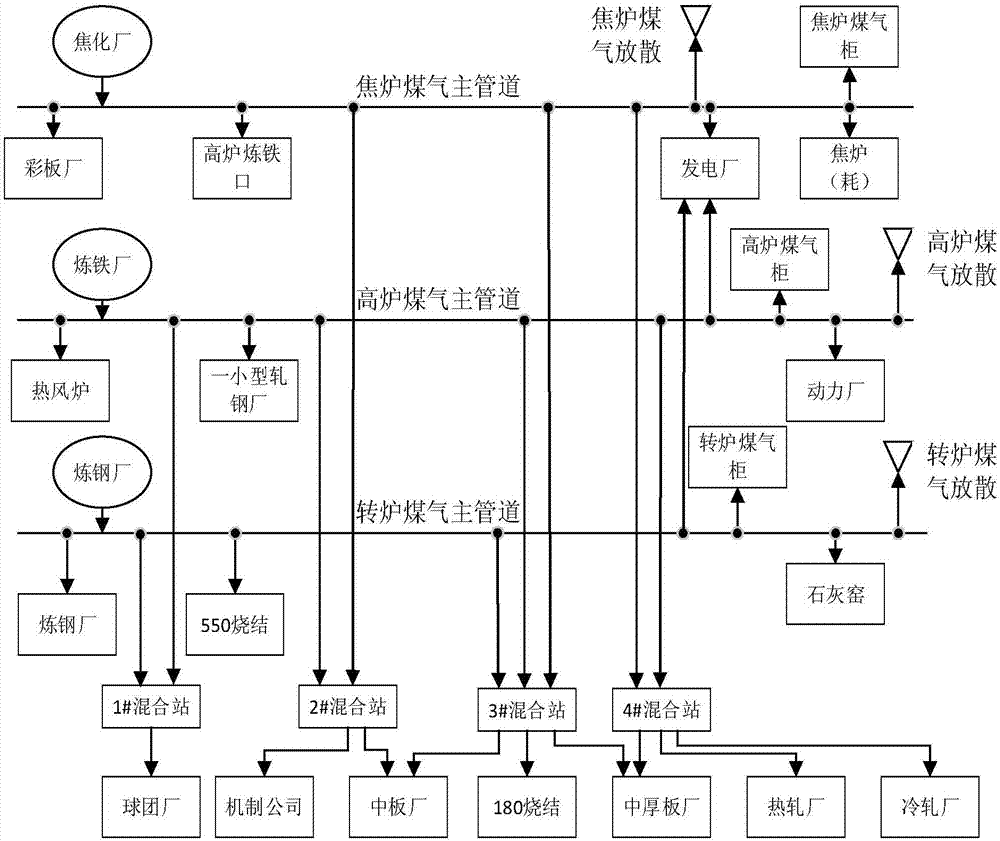

[0075] A timing optimization method for gas consumption equipment in iron and steel enterprises, including three parts, the first part is the classification of gas equipment and the establishment of gas production and consumption characteristic models, the second part is the establishment of timing optimization models for gas consumption equipment, and the third part is the model Solve, the process block diagram of a kind of genetic algorithm-based timing optimization method for iron and steel enterprises of the present invention is as follows figure 1 shown. The object of the model is the gas system of an iron and steel enterprise, such as figure 2 As shown, the system includes gas production equipment, gas consumption equipment, gas buffer equipment, and gas mixing station.

[0076] 1. The specific implementation of the first part abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com