Solar cell backboard and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of short service life, poor durability of the backplane, poor mechanical properties of the backplane, etc., so as to improve the service life, Improved peel strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

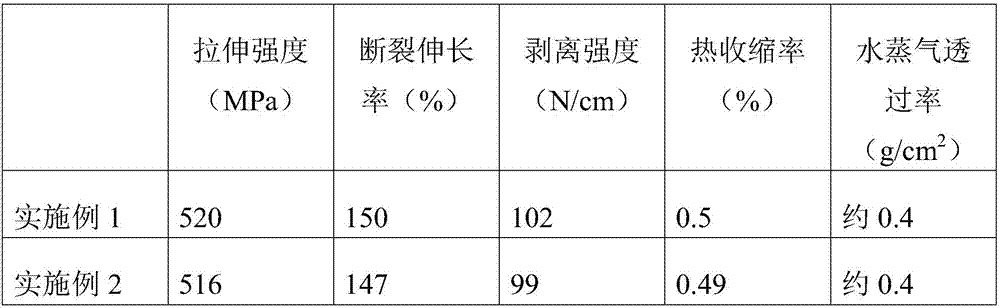

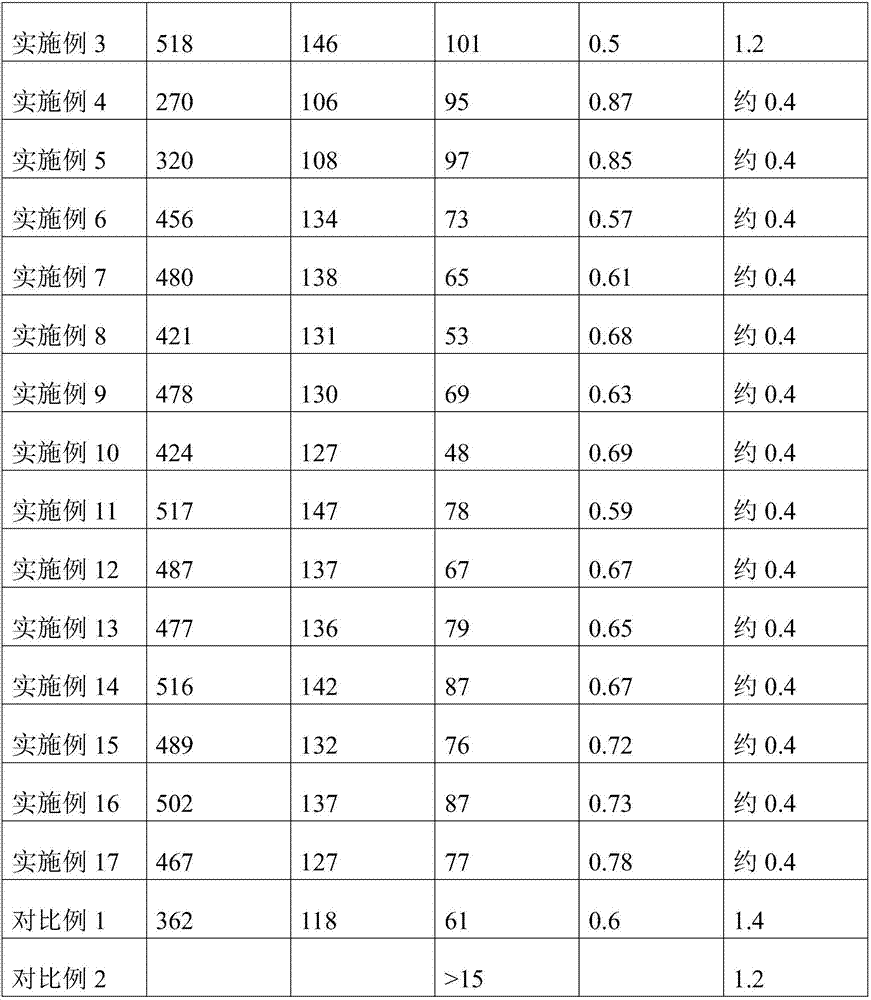

Examples

Embodiment 1

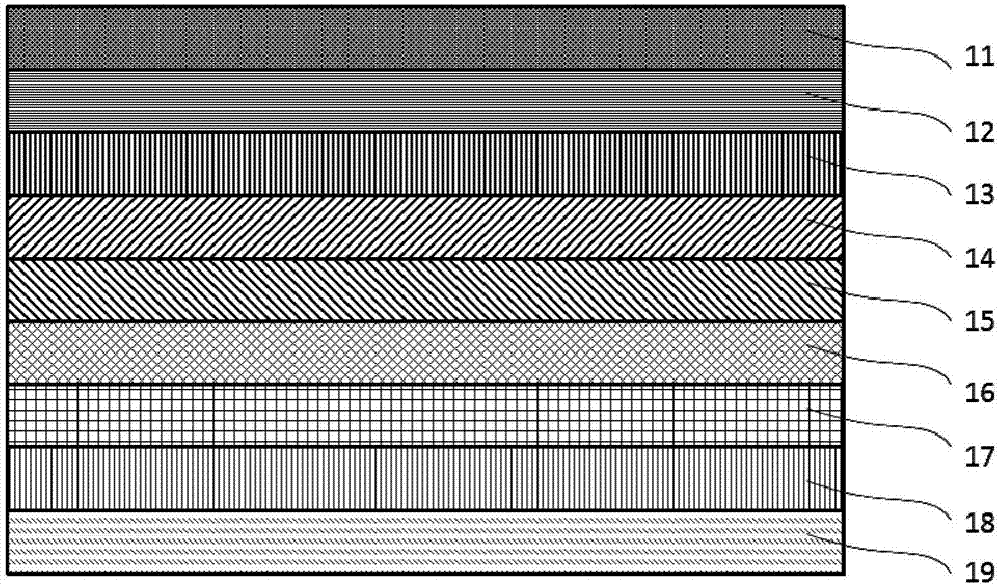

[0024] The solar cell backsheet includes from bottom to top: the bottom inorganic weather-resistant layer, the first polymer weather-resistant layer, the second polymer weather-resistant layer, the first structural reinforcement layer, the second structural reinforcement layer, the third structural reinforcement layer, the Three polymer weather-resistant layers, the fourth polymer weather-resistant layer and the top inorganic weather-resistant layer, wherein, at 150-200°C, the viscosity of the first polymer weather-resistant layer is greater than the viscosity of the second polymer weather-resistant layer, and the second polymer The viscosity of the weather-resistant layer is greater than that of the first structurally enhanced layer, and the viscosity of the first structurally enhanced layer is greater than that of the second structurally enhanced layer. At 150-200°C, the viscosity of the fourth polymer weather-resistant layer is greater than the viscosity of the third polymer...

Embodiment 2

[0026]The solar cell backsheet includes from bottom to top: the bottom inorganic weather-resistant layer, the first polymer weather-resistant layer, the second polymer weather-resistant layer, the first structural reinforcement layer, the second structural reinforcement layer, the third structural reinforcement layer, the Three polymer weather-resistant layers, the fourth polymer weather-resistant layer and the top inorganic weather-resistant layer, wherein, at 150-200°C, the viscosity of the first polymer weather-resistant layer is greater than the viscosity of the second polymer weather-resistant layer, and the second polymer The viscosity of the weather-resistant layer is greater than that of the first structurally enhanced layer, and the viscosity of the first structurally enhanced layer is greater than that of the second structurally enhanced layer. At 150-200°C, the viscosity of the fourth polymer weather-resistant layer is greater than the viscosity of the third polymer ...

Embodiment 3

[0028] The solar cell backsheet includes from bottom to top: the first polymer weather-resistant layer, the second polymer weather-resistant layer, the first structural reinforcement layer, the second structural reinforcement layer, the third structural reinforcement layer, the third polymer weather-resistant layer, Fourth polymer weathering layer. All the other conditions and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com