Novel rotating zigzag high-gravity bed

A supergravity rotating bed, baffled flow technology, applied in chemical/physical/physical-chemical fixed reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc. To solve the problems of limited separation capacity of the equipment, it achieves the effect of low purchase and operation cost, convenient use and maintenance, and low height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

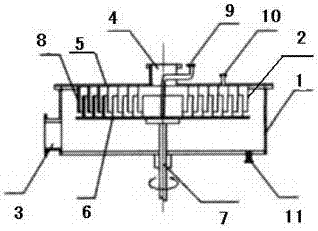

[0009] Such as figure 1 As shown, a new type of baffled supergravity rotating bed is composed of a shell 1 and a baffled rotor 2, the left side of the shell 1 is connected to the gas inlet pipe 3, and the middle part of the upper end of the shell 1 is connected to the gas outlet pipe 4. The baffle rotor 2 is composed of a stationary disk 5 and a rotating disk 6. The stationary disk 5 is fixedly connected to the casing 1, and the rotating disk 6 is connected to the rotating shaft 7 arranged in the middle of the casing 1 and rotates together with the rotating shaft. A certain number of baffle rings 8 are concentrically installed on the disk 5 and the rotating disk 6 according to a certain distance. The stationary disk 5 and the rotating disk 6 outside the baffle rings 8 are nested together. 9. A liquid feed pipe 10 is provided on the right side, and a liquid outlet pipe 11 is provided on the right side of the lower end of the housing 1 .

[0010] There is a certain distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com