Preparation method and application of biological microcapsule

A microcapsule and biological technology, applied in the field of water treatment, can solve problems such as insufficient utilization, and achieve the effects of improving load and stability, simple preparation process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

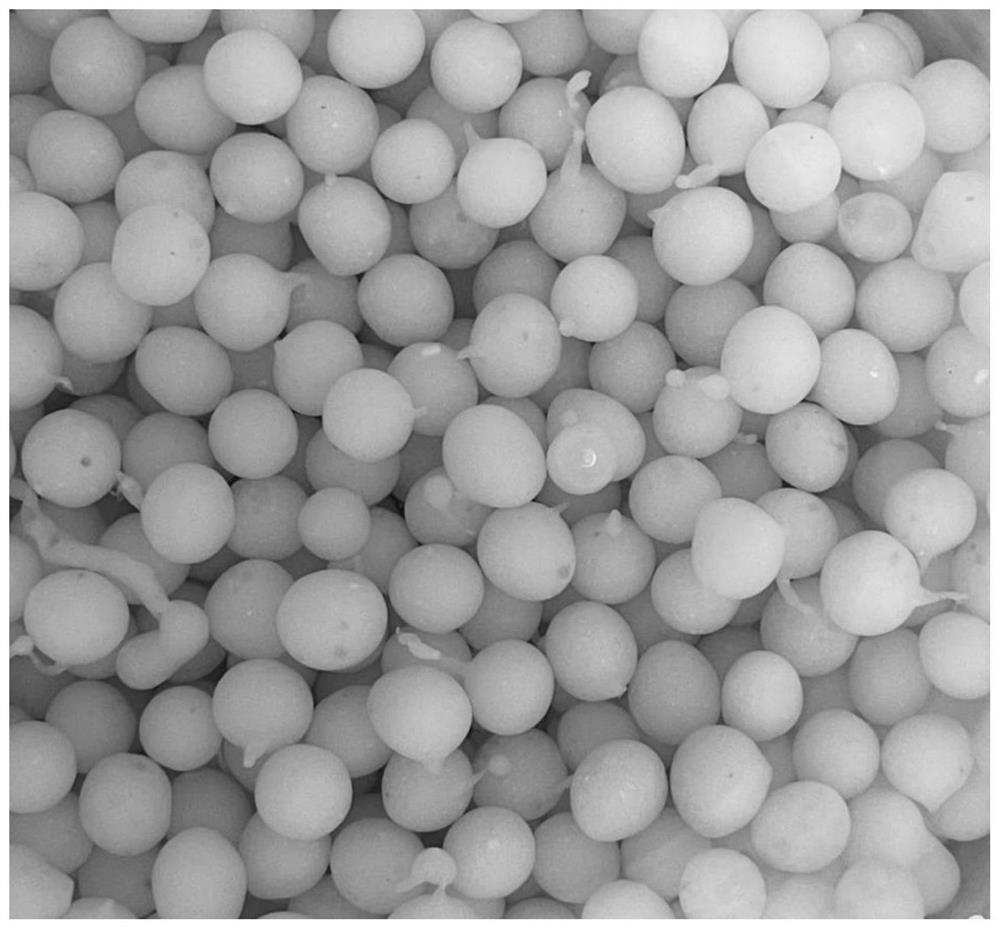

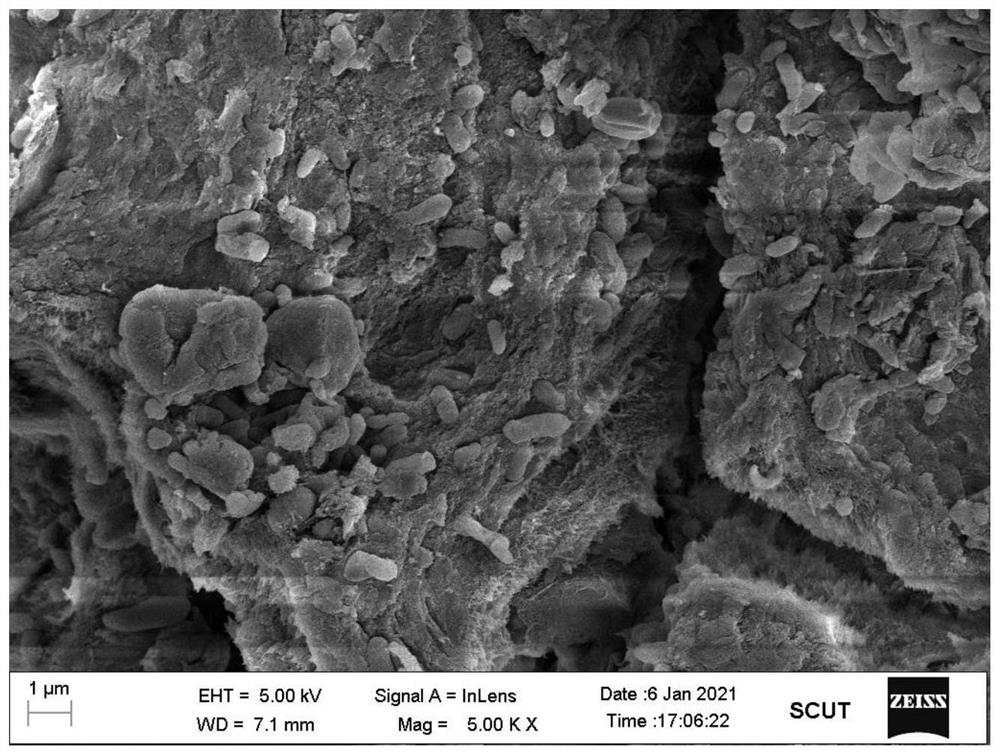

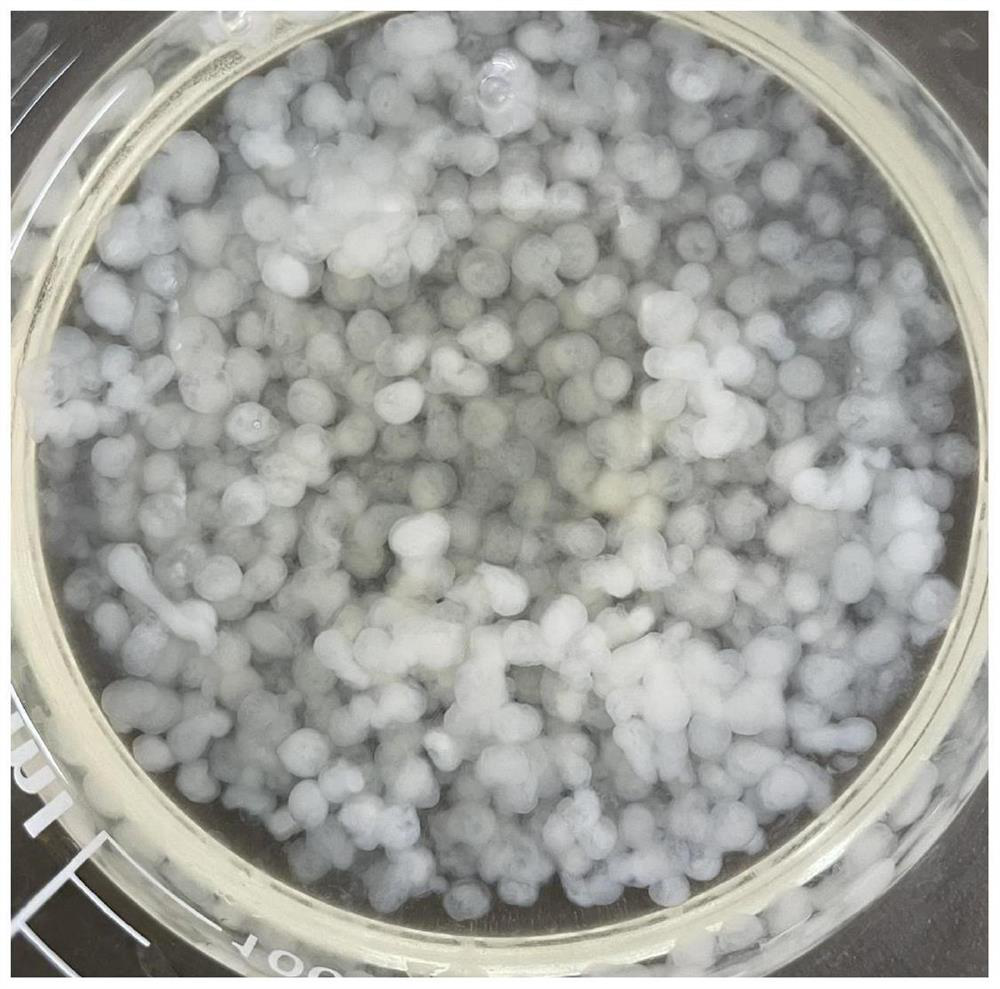

[0043](1) Heat and dissolve 2 g of polyvinyl alcohol (polymerization degree 1700, alcoholysis degree 99%) and 2 g of sodium alginate powder in 50 mL of deionized water at 95°C, and stir until there are no bubbles. Dry, pulverize and sieve 2g of corncobs (0.075-0.180mm) into the polyvinyl alcohol-sodium alginate mixture, put the mixture into a sterilizer, sterilize at 125°C for 20min, and cool to room temperature. Add 20mL microbial growth promoter (containing amino acid solution 10mL, vitamin solution 10mL), add 30mL compound denitrifying bacteria suspension (the volume ratio of nitrifying bacteria and aerobic denitrifying bacteria is 1:1.5) and stir well to mix Evenly, the mixed solution of polyvinyl alcohol, sodium alginate, corn cob, microbial growth-promoting agent and compound denitrification bacteria suspension (corn cob: microbial growth-promoting agent: composite bacteria suspension=2%:20% :30%).

[0044] (2) Add the mixed solution prepared above dropwise into 2% calc...

Embodiment 2

[0046] A kind of biological microcapsule that embeds composite denitrification bacteria, microbial growth-promoting agent and corncob is basically the same as the biological microcapsule prepared in Example 1, the difference is only: the quality of corncob in the biological microcapsule of Example 2 The content is 1g.

[0047] (1) Heat and dissolve 2g of polyvinyl alcohol 1799 type and 2g of sodium alginate powder in 50mL of deionized water at 95°C, and stir evenly. Dry, crush and sieve 1g of corncob (0.075-0.180mm) into the polyvinyl alcohol-sodium alginate mixture, put the mixture into a sterilizer, sterilize at 125°C for 20min, and cool to room temperature. Add 20mL microbial growth promoter (containing amino acid solution 10mL, vitamin solution 10mL), add 30mL compound denitrifying bacteria suspension (the volume ratio of nitrifying bacteria and aerobic denitrifying bacteria is 1:1) and stir well to mix Evenly, the mixed solution of polyvinyl alcohol, sodium alginate, cor...

Embodiment 3

[0050] A kind of biological microcapsule embedded with compound denitrification bacteria, microbial growth promoter and corn cob is basically the same as the biological microcapsule prepared in Example 1, the difference is only: the microbial growth promotion in the preparation method of Comparative Example 1 The dose volume is 10 mL.

[0051] (1) Heat and dissolve 2g of polyvinyl alcohol 1799 type and 2g of sodium alginate powder in 50mL of deionized water at 95°C, and stir evenly. Dry, pulverize and sieve 2g of corn cobs (0.075-0.180mm in particle size) into the polyvinyl alcohol-sodium alginate mixture, then add 10mL of the microbial growth promoter in Example 1, put the mixture into a sterilizer, Sterilize at 125°C for 20 minutes. After cooling to room temperature, add 30mL of the compound denitrification bacteria suspension in Example 1 and stir well to make it evenly mixed to prepare polyvinyl alcohol, sodium alginate, corn cob, microbial growth promoter and compound de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com