Four-jaw chuck

A four-jaw chuck and chuck body technology, applied in auxiliary devices, applications, laser welding equipment, etc., to achieve the effects of improving clamping efficiency, improving position accuracy, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

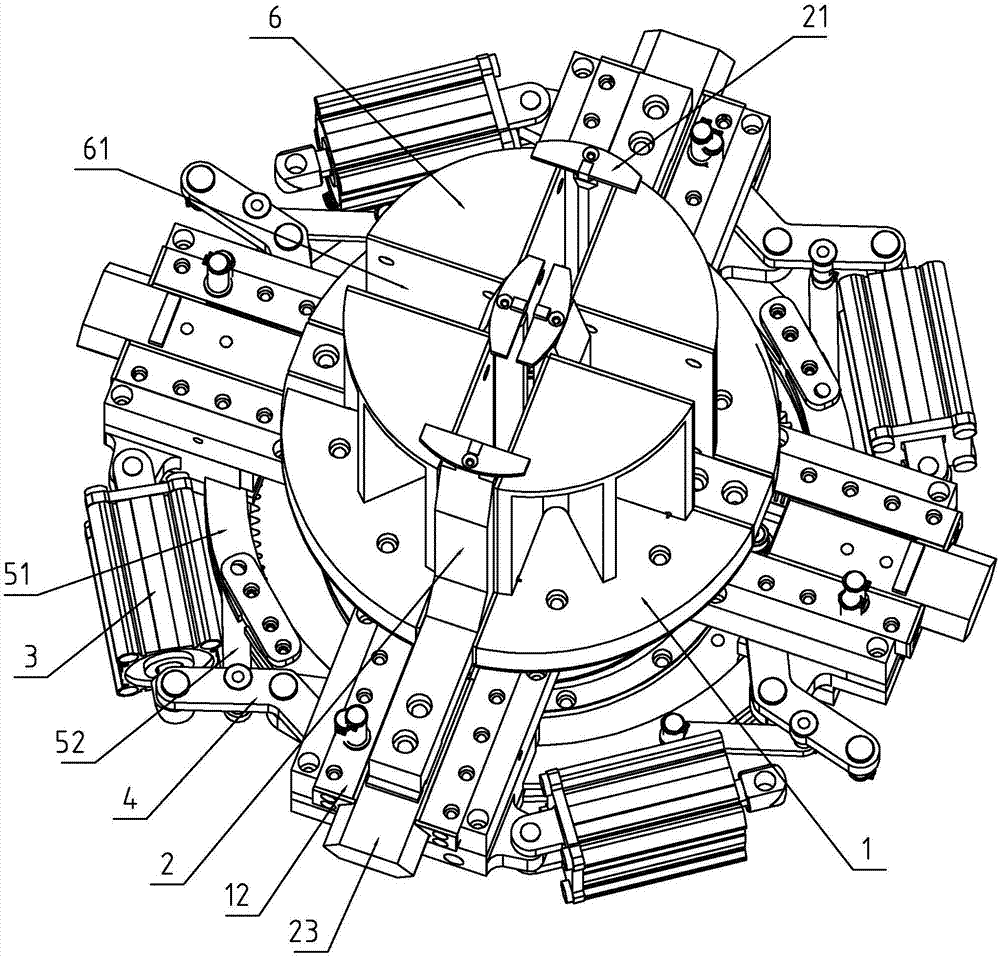

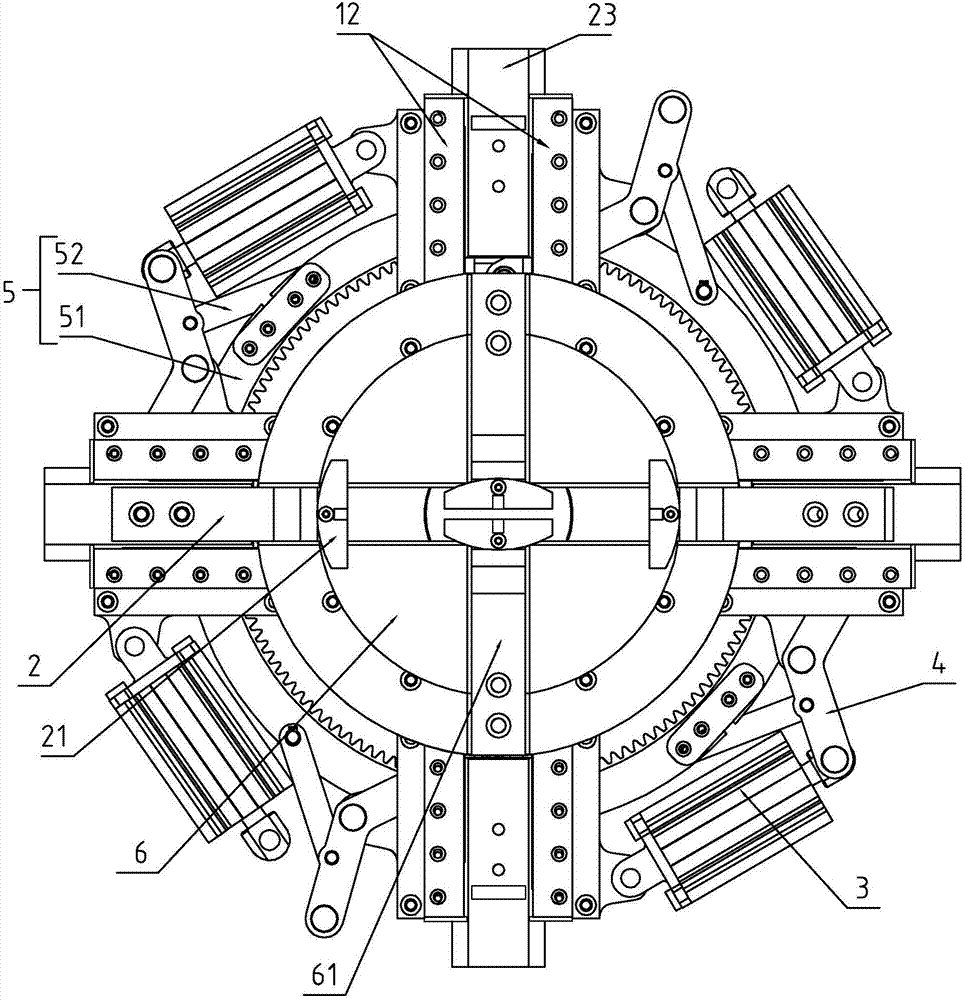

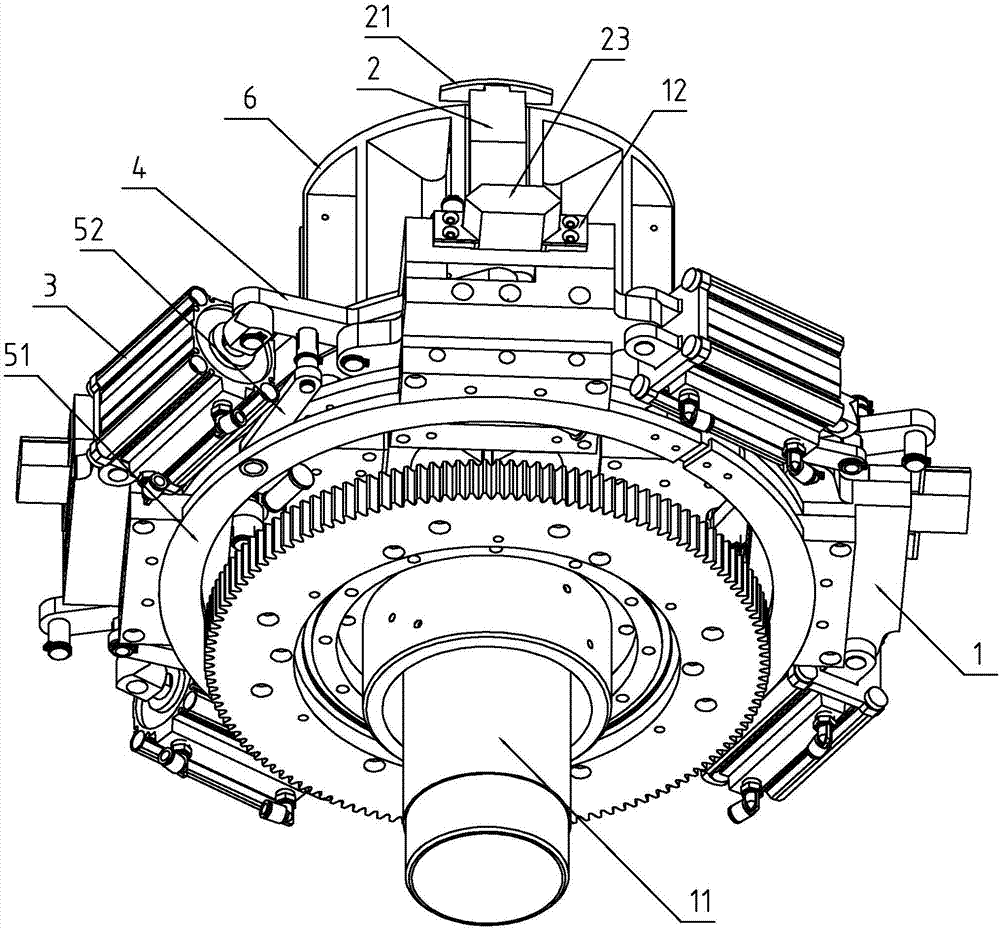

[0018] refer to Figure 1-6 As shown, a four-jaw chuck includes a chuck body 1 and jaws 2 that are slidably connected to the chuck body 1. There are four jaws 2 that are evenly distributed on the chuck body 1 in a ring shape. Above, the four claws 2 are set opposite to each other, and the sliding tracks of the four claws 2 on the chuck body 1 are arranged in a cross-shaped structure, and the intersection point of the cross-shaped sliding track and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com