An energy-saving, heat-insulating, UV-resistant building curtain wall glass

An anti-ultraviolet and anti-ultraviolet coating technology, which is applied in the direction of glass/slag layered products, coatings, chemical instruments and methods, etc., can solve the problem of poor heat insulation and anti-ultraviolet function, loss of installation of glass curtain walls, and unsatisfactory use Requirements and other issues, to achieve the effect of adjustable transparency, improved heat insulation effect, and good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

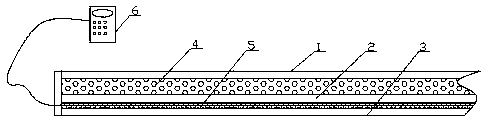

[0015] Embodiment 1: A kind of energy-saving, heat-insulating and anti-ultraviolet building curtain wall glass, as attached figure 1 As shown, it includes a first glass substrate 1 on the outside, a second glass substrate 2 in the middle and a third glass substrate 3 on the inside; the outer surface of the first glass substrate 1 is provided with anti-ultraviolet coating, a silica airgel layer 4 is provided between the first glass substrate 1 and the second glass substrate 2, and a silica airgel layer 4 is provided between the second glass substrate 2 and the third glass substrate 3 Transparent conductive film layer 5, transparent conductive film layer 5 is connected with controller 6; Described anti-ultraviolet coating comprises by weight: 4.9 parts of dimethylformamide, 6.6 parts of polyurethane, 3.5 parts of dodecyl alcohol ester, 0.08 parts of nano-alumina.

[0016] The silica airgel layer 4 is made of hydrophobic silica airgel.

Embodiment 2

[0017] Embodiment 2: A kind of energy-saving, heat-insulating and anti-ultraviolet building curtain wall glass, as attached figure 1 As shown, it includes a first glass substrate 1 on the outside, a second glass substrate 2 in the middle and a third glass substrate 3 on the inside; the outer surface of the first glass substrate 1 is provided with anti-ultraviolet coating, a silica airgel layer 4 is provided between the first glass substrate 1 and the second glass substrate 2, and a silica airgel layer 4 is provided between the second glass substrate 2 and the third glass substrate 3 Transparent conductive film layer 5, transparent conductive film layer 5 is connected with controller 6; Described anti-ultraviolet coating comprises by weight: 3.8 parts of dimethylformamide, 5.1 parts of polyurethane, 2.2 parts of dodecyl alcohol ester, 0.03 parts of nano-alumina.

[0018] The silica airgel layer 4 is made of hydrophobic silica airgel.

Embodiment 3

[0019] Embodiment 3: A kind of energy-saving, heat-insulating and anti-ultraviolet building curtain wall glass, as attached figure 1 As shown, it includes a first glass substrate 1 on the outside, a second glass substrate 2 in the middle and a third glass substrate 3 on the inside; the outer surface of the first glass substrate 1 is provided with anti-ultraviolet coating, a silica airgel layer 4 is provided between the first glass substrate 1 and the second glass substrate 2, and a silica airgel layer 4 is provided between the second glass substrate 2 and the third glass substrate 3 Transparent conductive film layer 5, transparent conductive film layer 5 is connected with controller 6; Described anti-ultraviolet coating comprises by weight: 6.4 parts of dimethylformamide, 8.6 parts of polyurethane, 4.5 parts of lauryl alcohol ester, 0.12 parts of nano-alumina.

[0020] The silica airgel layer 4 is made of hydrophobic silica airgel.

[0021] It is also possible to install a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com