A refining process for reducing chloropropanol esters in camellia oil

The technology of chloropropanol ester and camellia oil is applied in the direction of fat oil/fat refining, fat production, etc., which can solve the problems of reducing the content of chloropropanol ester compounds, increasing the potential harm of 3-chloropropanol ester, etc., and achieves the separation degree. And high yield, improve degumming effect, improve the effect of process procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] A refining process for reducing chloropropanol esters in camellia oil, comprising the following steps:

[0019] 1) Filter the crude oil, which contains a small amount of colloid, remove mechanical impurities through filtration, then preheat, add water for hydration, set aside to settle, and separate to obtain oil and hydration oil; take hydration oil and add water, then add Phosphoric acid, instead of salt, reduces the source of Cl, neutralizes non-hydrophilic colloidal substances, improves the degumming effect, and finally neutralizes it with 0.5% liquid natron, stands for precipitation, and separates oil and soap;

[0020] 2) Crude oil is put into the decolorizing pot for decolorization, and is carried out in the decolorizing pot according to the conventional process;

[0021] 3) Deacidification and deodorization; then heating under the condition of low vacuum in the molecular distillation equipment, with the help of the difference in the free travel of each component...

experiment example

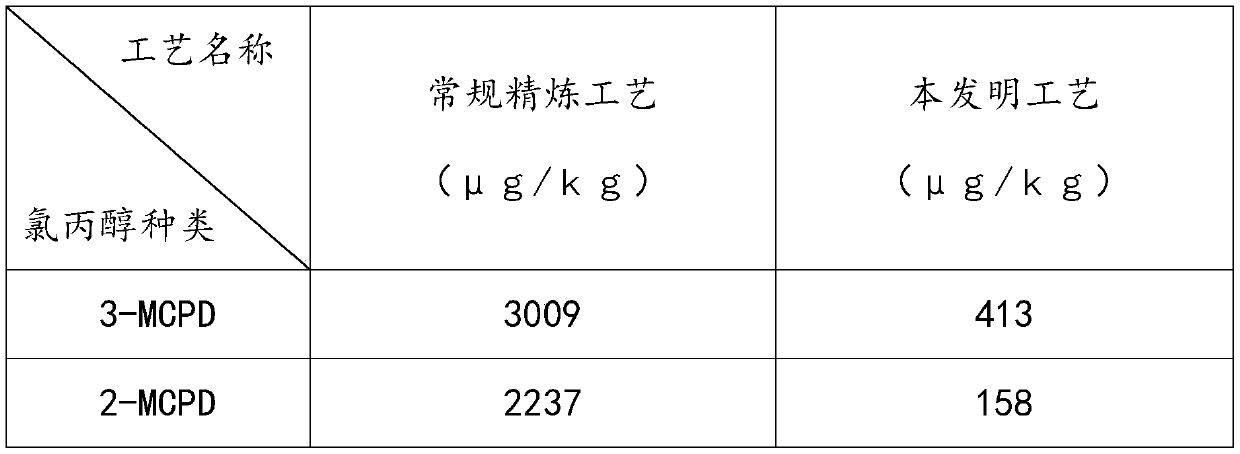

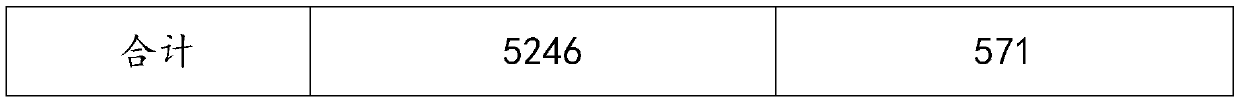

[0027] In addition to complying with the "Hygienic Standard for Edible Oil" GB2716-2005, the oil prepared by the above method also has the following advantages (number of test samples n=9)

[0028]

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com