Flux-cored welding wire for oil and gas transmission pipeline and preparation method thereof

A technology for conveying pipes and flux-cored wires, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of low-temperature toughness of welded joints, unstable low-temperature impact value, unreasonable composition design, etc., to reduce weld structure Impurities, facilitate slag forming and covering performance, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

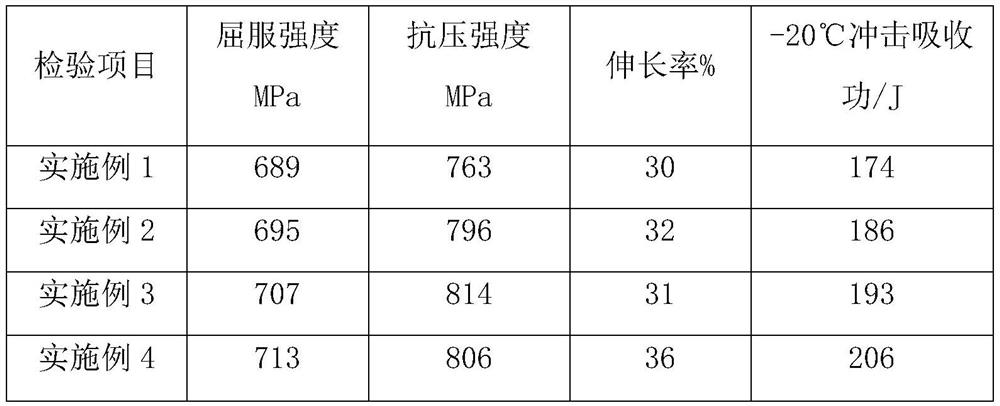

Examples

Embodiment 1

[0025] Flux-cored welding wire for oil and gas transmission pipelines is composed of a flux core and a low-carbon steel strip wrapped around the flux core. The flux core accounts for 12% of the total weight of the flux-cored welding wire for oil and gas transmission pipelines. Redstone powder 5%, nickel powder 3%, zirconium powder 3%, white corundum powder 1%, yttrium trioxide 1%, manganese silicon alloy powder 2%, chromium ferroalloy powder 1%, magnesium oxide powder 1%, molybdenum ferroalloy powder 0.5%, tungsten carbide powder 0.5%, rare earth fluoride 0.5%, cerium oxide 0.1%, and the balance is iron powder. The sum of the mass percentages of the above components is 100%, and the silicon-manganese ratio in the manganese-silicon alloy powder is 30%. : 70; the chromium content in the ferrochrome alloy powder is 30wt%; the molybdenum content in the ferromolybdenum alloy powder is 50wt%.

[0026] The preparation method of flux-cored welding wire for oil and gas pipelines is as ...

Embodiment 2

[0030] Flux-cored welding wire for oil and gas transmission pipelines is composed of a flux core and a low-carbon steel strip wrapped around the flux core. The flux core accounts for 15% of the total weight of the flux-cored welding wire for oil and gas transmission pipelines. Redstone powder 6%, nickel powder 4%, zirconium powder 4%, white corundum powder 2%, yttrium trioxide 2%, manganese silicon alloy powder 3%, chromium ferroalloy powder 3%, magnesium oxide powder 2%, molybdenum ferroalloy powder 1%, tungsten carbide powder 1%, rare earth fluoride 1%, cerium oxide 0.2%, and iron powder as the balance, the sum of the above components by mass percentage is 100%, and the silicon-manganese ratio in the manganese-silicon alloy powder is 30% : 70; the chromium content in the ferrochromium alloy powder is 35wt%; the molybdenum content in the ferromolybdenum alloy powder is 55wt%.

[0031] The preparation method of flux-cored welding wire for oil and gas pipelines is as follows: ...

Embodiment 3

[0035] Flux-cored welding wire for oil and gas pipelines consists of a flux core and a low-carbon steel strip wrapped around the core. The flux core accounts for 20% of the total weight of the flux-cored wire for oil and gas pipelines. The flux core contains the following components in mass percentage: Redstone powder 10%, nickel powder 6%, zirconium powder 6%, white corundum powder 4%, yttrium trioxide 3%, manganese silicon alloy powder 5%, chromium ferroalloy powder 5%, magnesium oxide powder 4%, molybdenum ferroalloy powder 2%, tungsten carbide powder 2%, rare earth fluoride 2%, cerium oxide 0.5%, and the balance is iron powder. The sum of the mass percentages of the above components is 100%, and the silicon-manganese ratio in the manganese-silicon alloy powder is 30%. : 70; the chromium content in the ferrochromium alloy powder is 35wt%; the molybdenum content in the ferromolybdenum alloy powder is 55wt%.

[0036] The preparation method of flux-cored welding wire for oil a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com