Performance optimization method of steam combined cycle unit of medium-power gas turbine

A combined cycle unit and combined cycle technology, applied in steam engine installations, combined combustion mitigation, gas turbine installations, etc., can solve problems such as cost increase, achieve good economic benefits, expand market sales, and rationally use energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

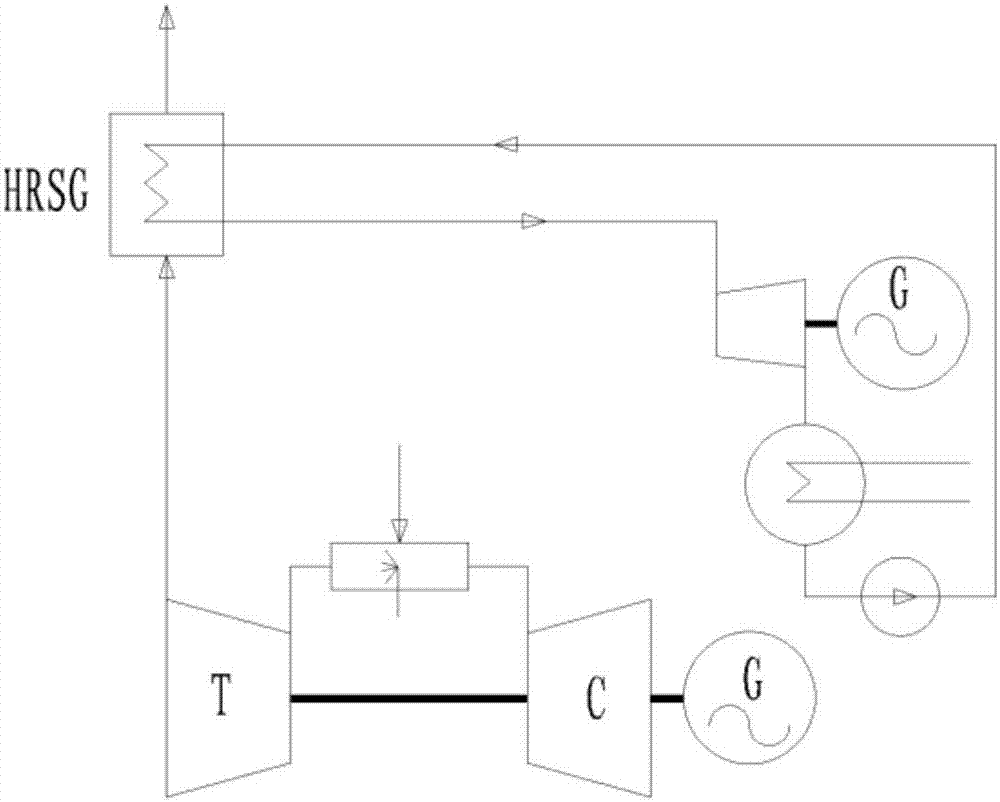

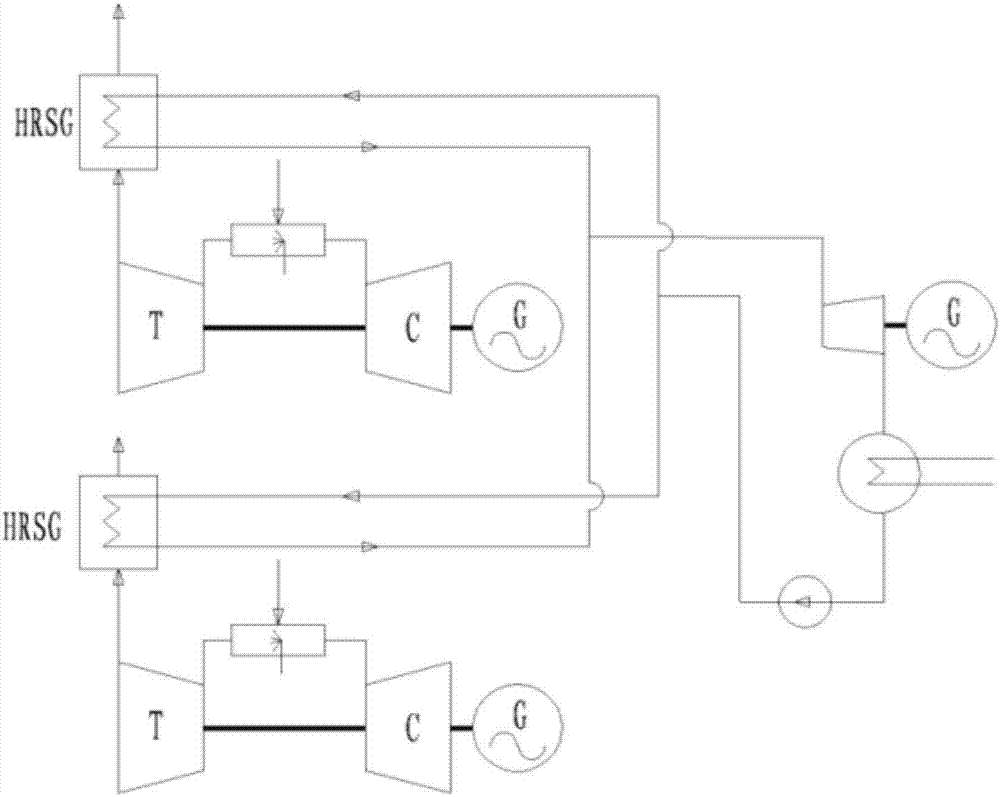

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the accompanying drawings.

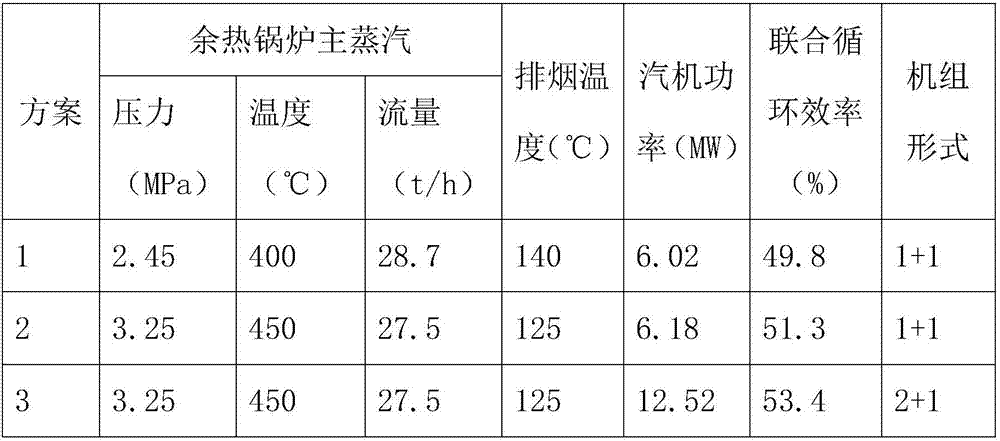

[0013] The gas turbine exhaust temperature is 476°C and the flue gas flow rate is 59.42kg / s. According to the design specifications of the combined cycle, the initial steam temperature depends on the exhaust gas temperature of the gas turbine, and the difference between the two is generally 25-60 °C.

[0014] In the calculation of the waste heat boiler, the temperature at the pinch point is 9°C, the temperature difference at the approach point is greater than 5°C, and the temperature difference between the superheated steam temperature and the flue gas temperature at the superheater inlet is greater than 15°C. According to this, the steam evaporation of the waste heat boiler is calculated, and when the steam pressure changes, the evaporation also changes accordingly, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com