Turbulent flow and rotational flow negative pressure drying machine

A negative pressure drying and turbulent flow technology, applied in the direction of dryers, drying solid materials, drying gas arrangement, etc., can solve the problems of dust particles overflowing, disturbing residents, increasing energy consumption and cost of processing, etc., to achieve heating degree and The degree of pulverization, sufficient pulverization, and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

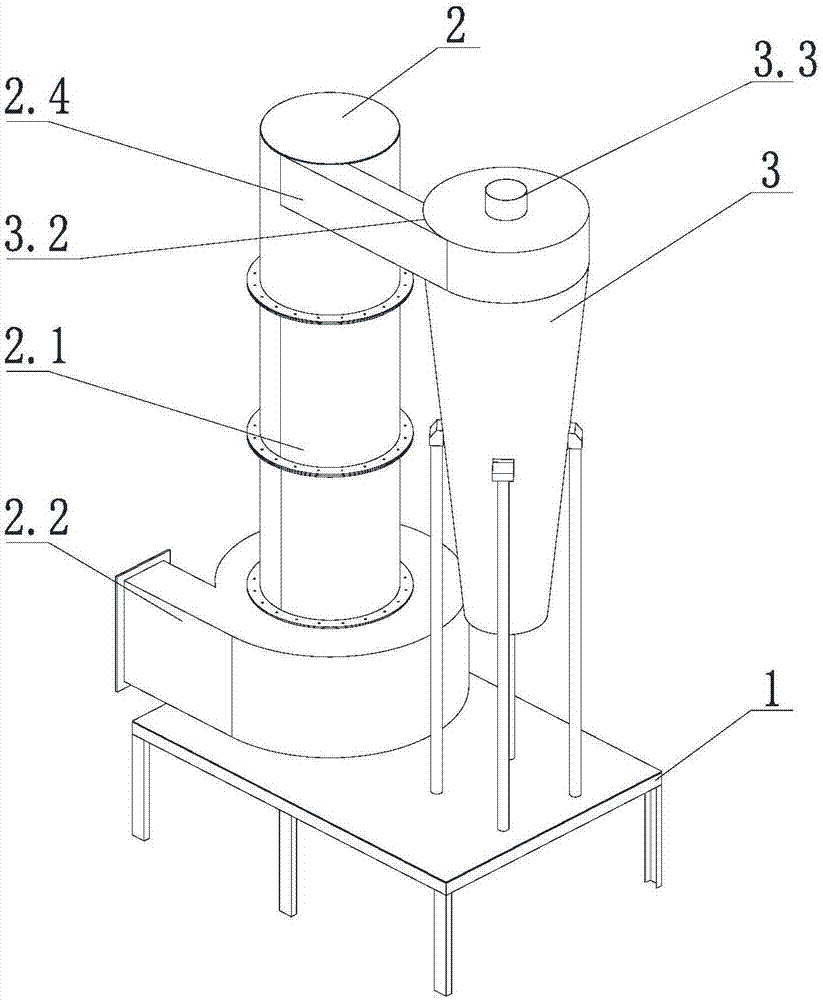

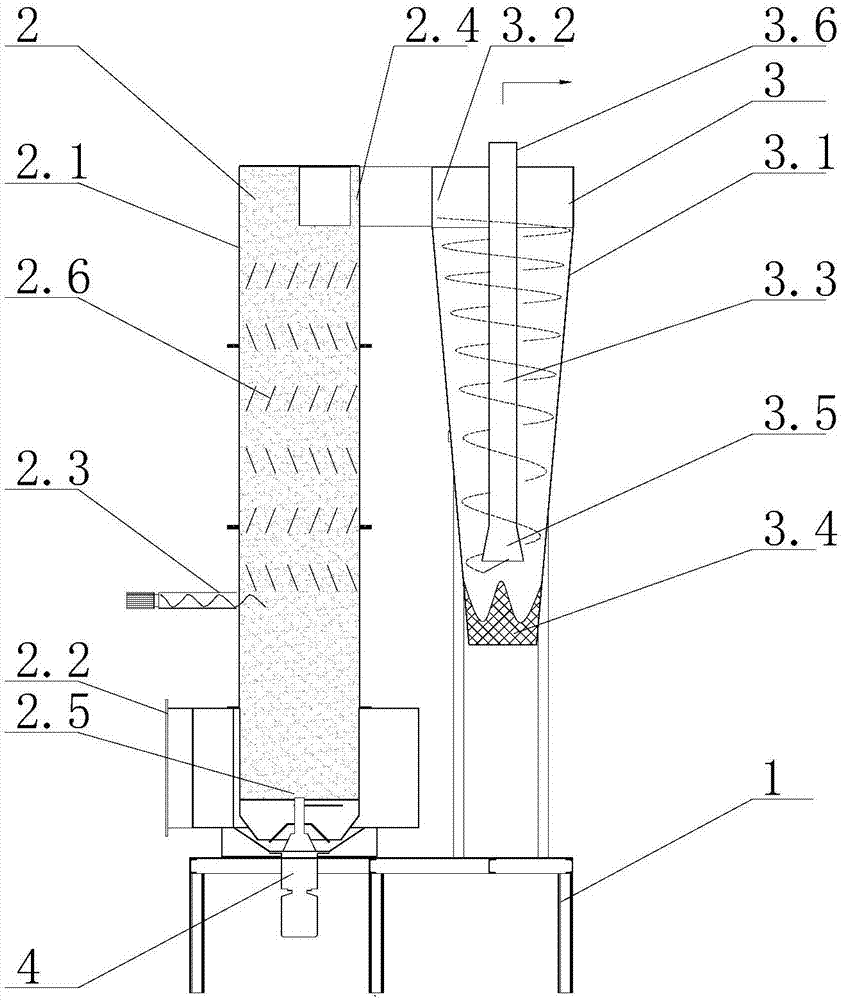

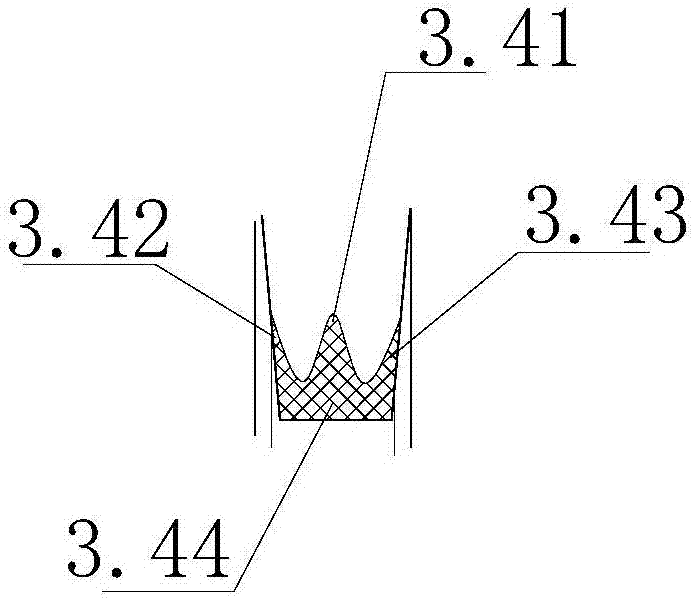

[0026] figure 1 , figure 2 The shown turbulent flow negative pressure dryer includes a machine base 1, on which a connected turbulent section 2 and a swirl section 3 are fixed, the turbulent section 2 includes a cavity 2.1, and the cavity 2.1 is a hollow circle Cylindrical, with airtight top and bottom surfaces, multiple rows of baffle arrays 2.6 for enhancing turbulent flow are arranged on the upper part of the inner wall of the cavity 2.1, a hot air inlet 2.2 is installed at the bottom of the cavity 2.1, and a humid material inlet 2.3 is arranged above the hot air inlet 2.2 , the upper end of the chamber 2.1 is provided with a hot air outlet 2.4, and the inner bottom of the chamber 2.1 is provided with a cutter 2.5 which is driven by a motor and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com