Wiring harness path generating system for full automatic wiring machine

A path generation and wiring machine technology, applied in special data processing applications, instruments, calculations, etc., can solve problems such as difficult to ensure the quality of path generation, reduce wiring harness wiring efficiency, increase worker workload, etc., to achieve intuitive display, enhanced The level of automation and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

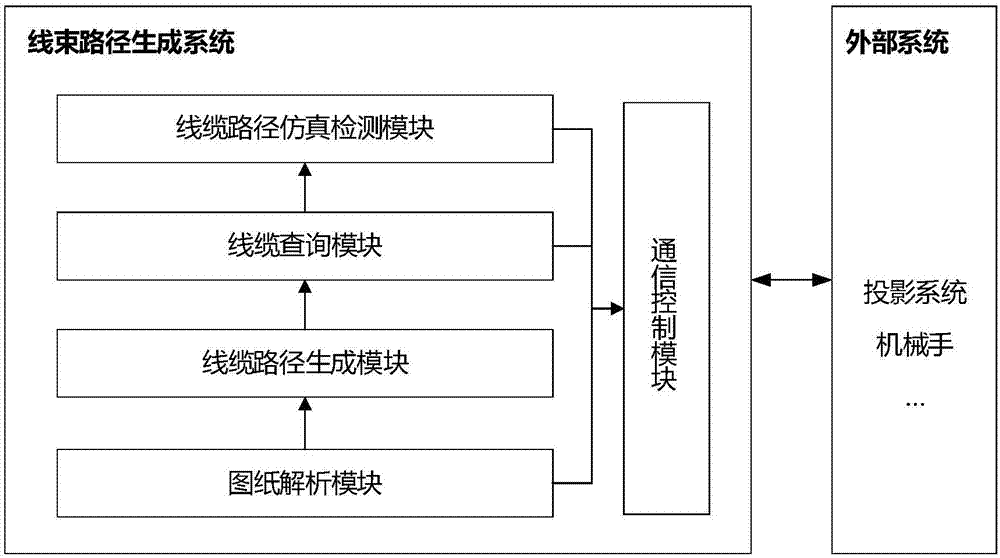

[0025] Such as figure 1 As shown, a wire harness path generation system for a fully automatic wiring machine includes: a drawing analysis module, a cable path generation module, a cable query module, and a path simulation detection module.

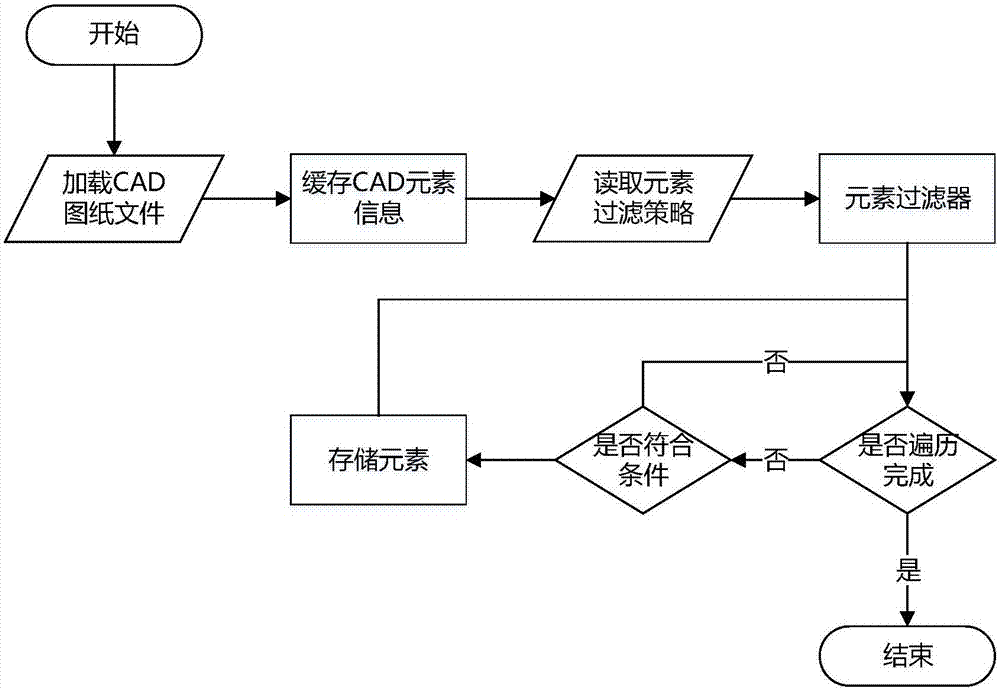

[0026] (1) The drawing parsing module is used to load and process drawing elements: import and read the CAD drawing of the wire harness, remove invalid elements in the drawing through the loaded element filtering strategy, and save the attribute information (such as position, type, handle, etc.) of the remaining valid elements ) are stored in the data cache, and provide data support for the cable path generation module.

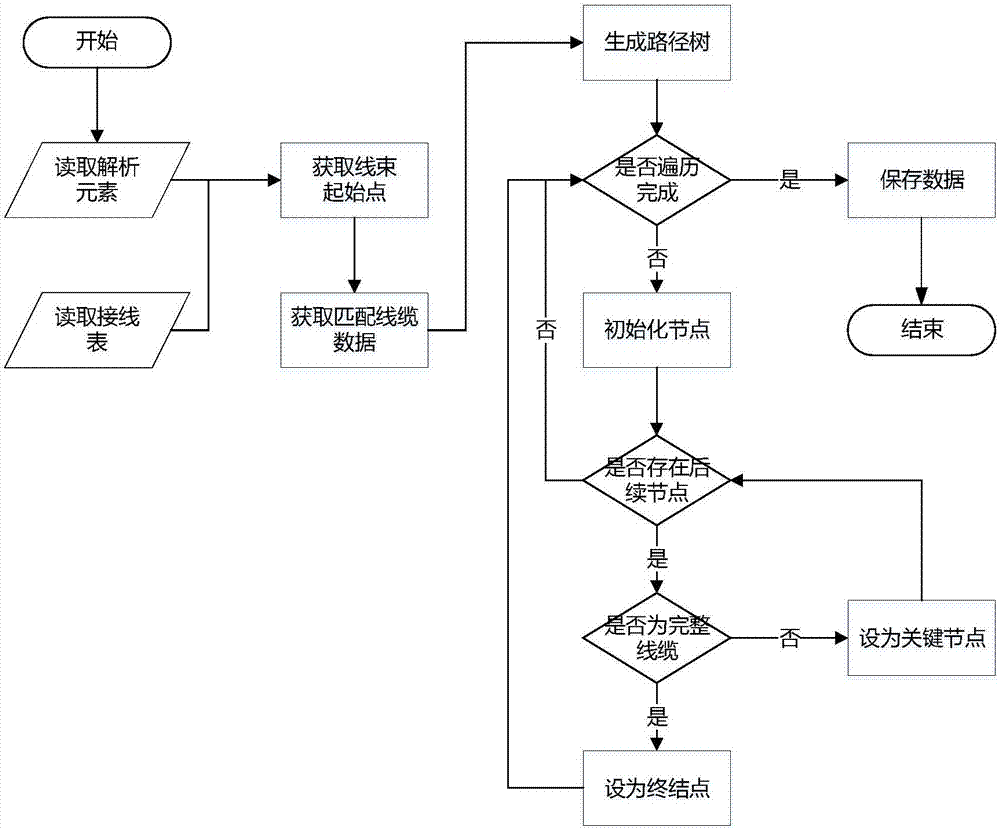

[0027] (2) The cable path generation module determines each cable through the loaded wiring harness wiring table (storing the models of all cables in the wiring harness, starting position, ending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com