Porous film, forming device thereof and application of porous film

A technology of porous film and forming device, which is applied in the field of sanitary products and can solve problems such as body fluid rewet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

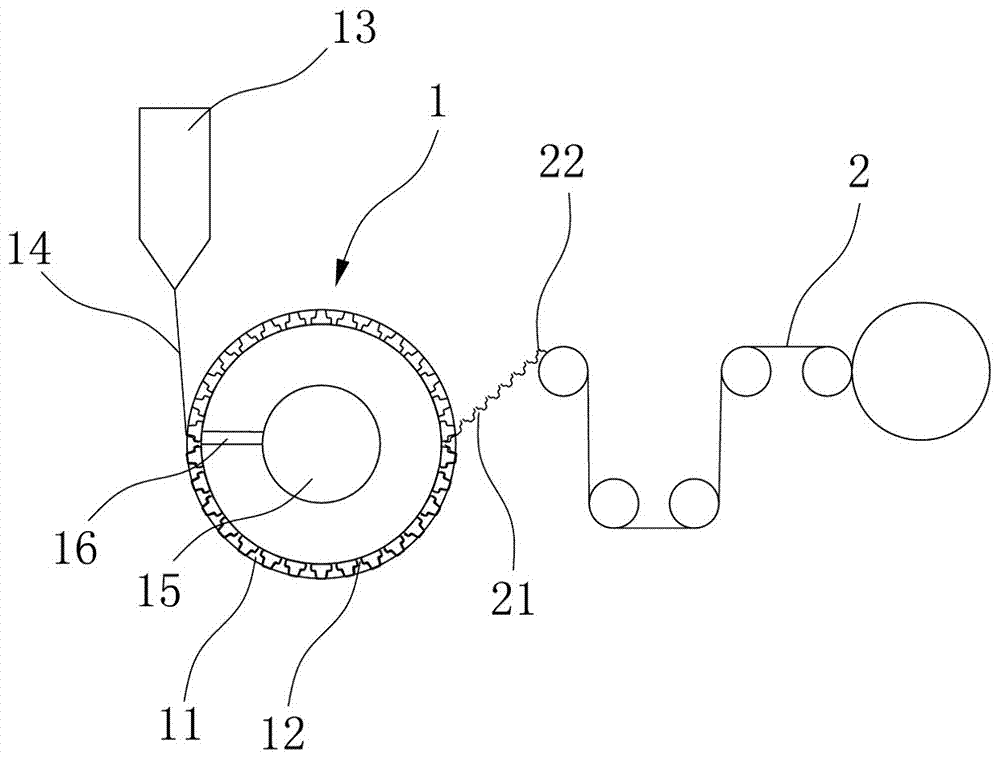

Method used

Image

Examples

Embodiment 1

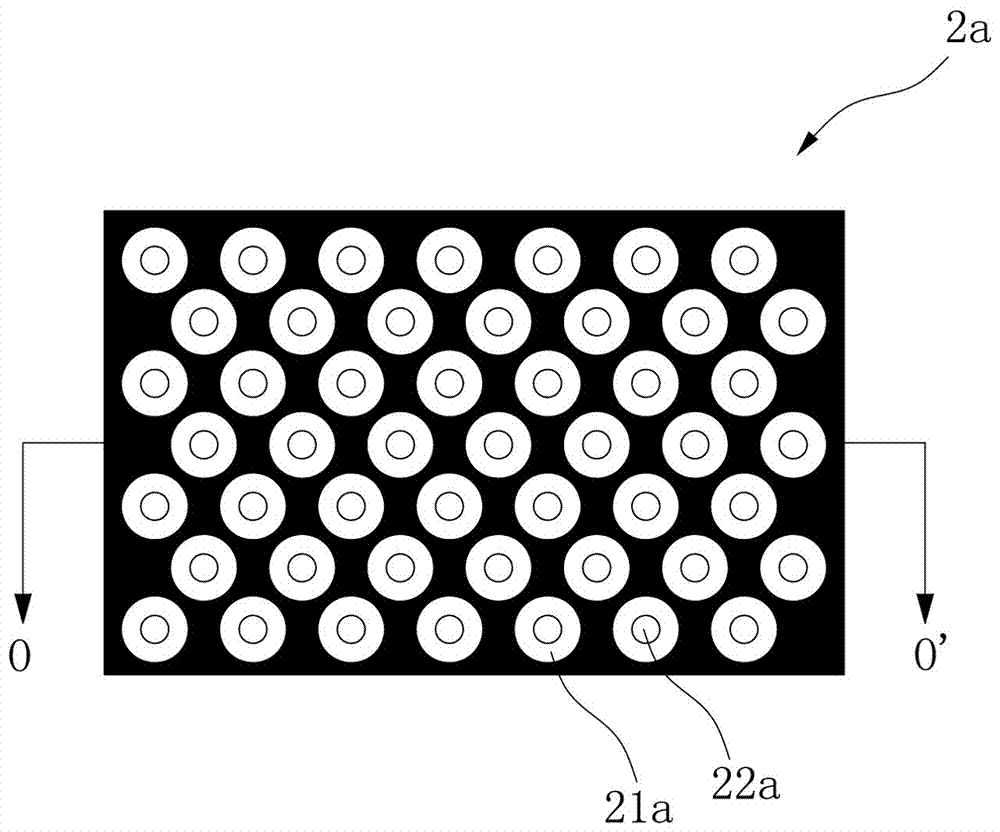

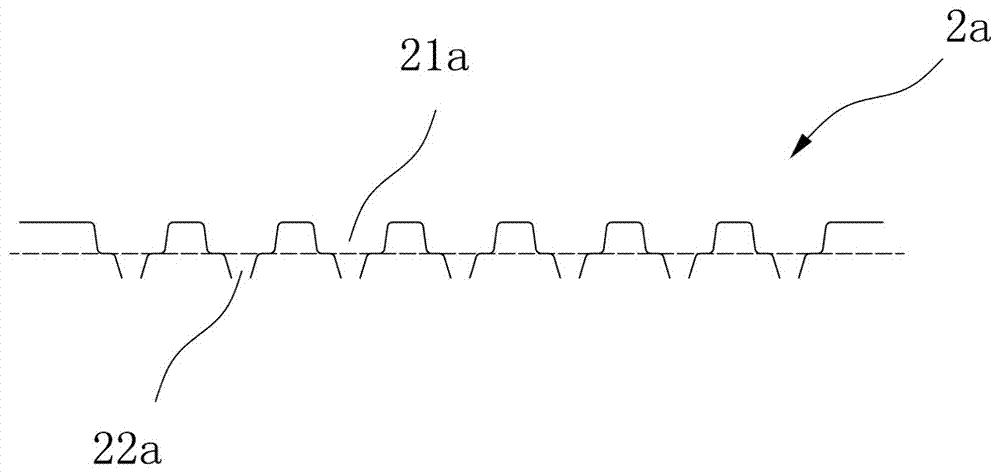

[0064] Such as figure 2 and image 3 As shown, the thickness of the porous film 2a is 0.8mm, the porous film 2a has circular depressions 21a distributed continuously through its surface layer and bottom layer, and a circular small hole 22a is embedded in the bottom of each depression, so The opening surface area of the small hole 22a is greater than the bottom area of the opening, the thickness of the depression 21a is twice the thickness of the small hole 22a, the equivalent diameter of the upper surface of the depression 21a is 1.5mm, and the equivalent diameter of the upper surface of the small hole 22a The diameter is 0.5 mm, the porosity of the upper surface of the depression 21a is 35%, the porosity of the small hole 22a is 15%, the equivalent diameter of the bottom of the depression 21a is greater than the equivalent diameter of the upper surface of the small hole 22a, the The gap between adjacent depressions 21a on the porous film 2a is 2 mm.

[0065] Such as ...

Embodiment 2

[0068] Such as Figure 5 and Figure 6 As shown, the thickness of the porous film 2b is 1.5mm, and the porous film 2b has hexagonal depressions 21b continuously distributed through its surface layer and bottom layer, and four circular small holes 22b are nested at the bottom of the depressions 21b. The opening surface area of the small hole 22b is greater than the bottom area of the opening, and the thickness of the depression 21b is 1.2 times the thickness of the small hole 22b. The equivalent diameter of the upper surface of the depression 21b is 2.5mm, and the upper surface of the small hole 22b The surface equivalent diameter is 0.8mm, the porosity of the depression 21b is 58%, the porosity of the small hole 22b is 20%, the equivalent diameter of the bottom of the depression 21b is larger than the upper surface equivalent diameter of the small hole 22b, the The gap between adjacent depressions on the porous film 2b was 0.8 mm.

[0069] Such as Figure 7 shown, for a...

Embodiment 3

[0072] Such as Figure 8 and Figure 9 As shown, the thickness of the porous film 2c is 1.6mm, and the porous film 2c has hexagonal depressions 21c distributed continuously through its surface layer and bottom layer, and a hexagonal small hole 22c is nested at the bottom of the depression 21c, The opening surface area of the small hole 22c is greater than the bottom area of the opening, and the thickness of the depression 21c is 1.0 times the thickness of the small hole 22c, and the equivalent diameter of the bottom of the depression 21c is equal to the equivalent diameter of the upper surface of the small hole 22c, The equivalent diameter of the upper surface of the depression 21c is 2.5mm, the equivalent diameter of the upper surface of the small hole 22c is 2.0mm, the porosity of the depression 21c is 58%, and the porosity of the small hole 22c is 30%. The gap between adjacent depressions on the porous film 2c is 0.8 mm.

[0073] Such as Figure 10 shown, for a manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gap | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com