A device for efficiently removing the weld reinforcement of composite stainless steel pipes

A technology of stainless steel pipe and weld excess height, which is used in grinding/polishing safety devices, parts of grinding machine tools, machine tools suitable for grinding workpiece edges, etc., can solve the problem of reducing the service life of the cutter head and inconvenient replacement , low welding speed and other problems, to achieve the effect of extending service life, good cutting quality and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

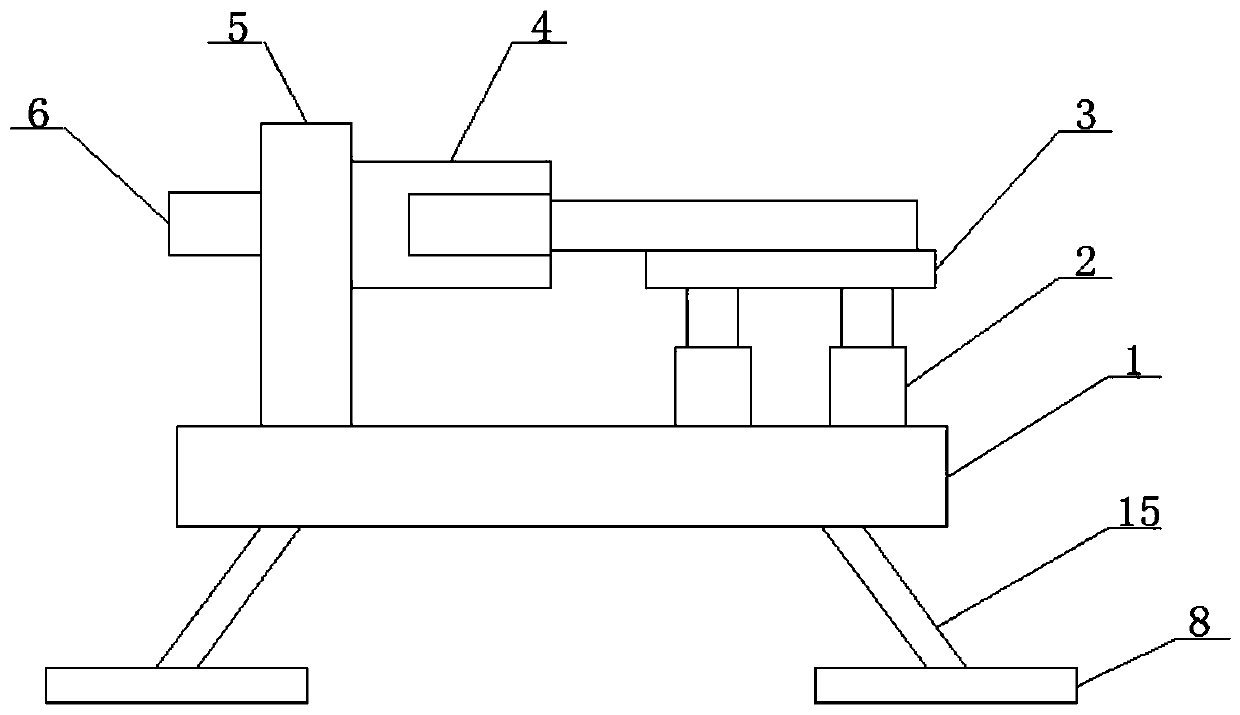

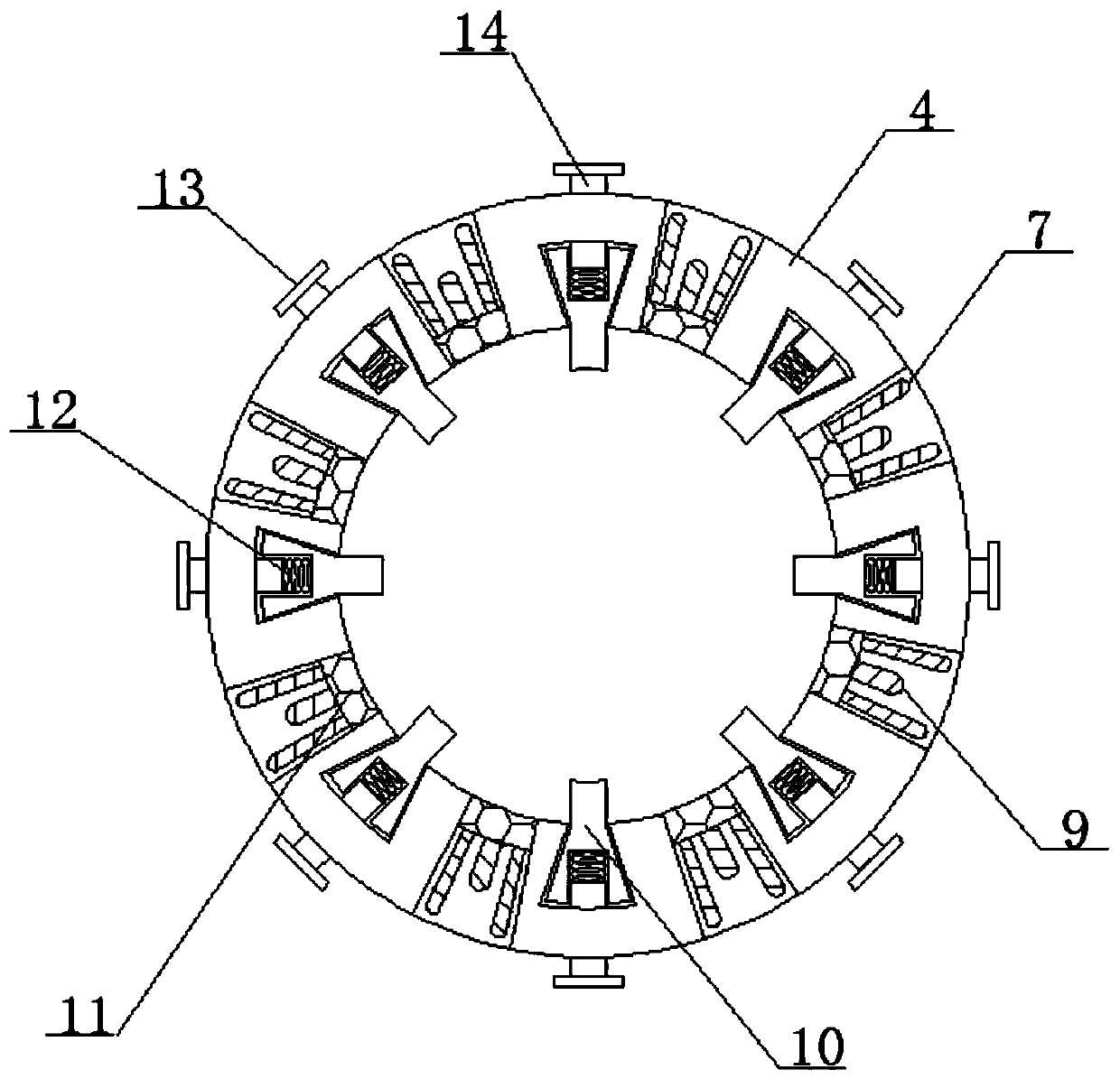

[0015] refer to Figure 1-2 , a device for efficiently removing the weld reinforcement of composite stainless steel pipes, comprising a base 1, the upper end of the base 1 is sequentially provided with a grinding device and a conveying device along the horizontal direction, the conveying device includes a hydraulic cylinder 2 fixedly connected to the upper end of the base 1, and the hydraulic cylinder The telescopic end of 2 is fixedly connected to the conveying platform 3. When in use, the operator puts the steel pipe to be polished on the conveying platform 3, and then turns on the switch of the hydraulic cylinder 2 to adjust the height of the conveying platform 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com