Sponge abrasive material and preparation method thereof

An abrasive and sponge technology is applied in the field of sponge abrasive and its preparation, which can solve the problems of increasing production links, easy falling off of hard abrasives, uneven heating, etc., and achieves the effects of reducing abrasive consumption, reducing production links and improving coating strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

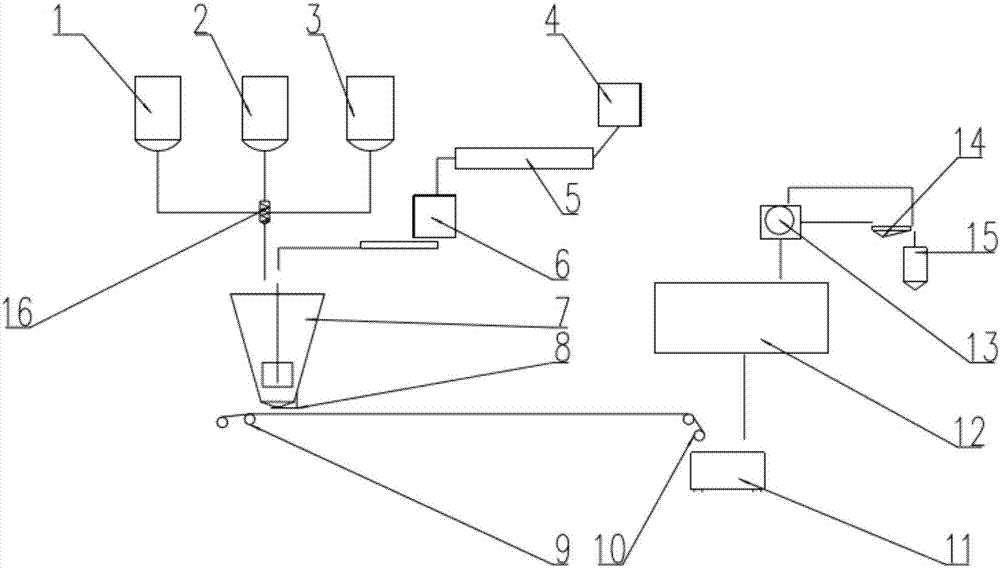

Image

Examples

Embodiment 1

[0032] Example 1 A sponge abrasive, comprising the following components by weight: 0.999 parts of polyurethane elastic material, 0.001 part of red pulp, and 2 parts of corundum.

[0033] The preparation method of above-mentioned sponge abrasive material, comprises the following steps:

[0034] Step 1: Heat the polyurethane elastic material to 40°C and mix it with the red paste to obtain a mixture. The mixture is quantified by a high-speed pouring machine, stirred by a high-speed stirring device, and then flows into a compound stirring device;

[0035] Step 2: Heat the corundum to 40°C through a continuous heating furnace, and then continuously flow into the compound stirring device through the quantitative device;

[0036] Step 3: Stir the mixture of polyurethane elastic material and red pulp flowing into the compound stirring device in step 1 and the corundum flowing into the compound stirring device evenly, so that the corundum is covered, and the compounded material is adju...

Embodiment 2

[0039] Example 2 A sponge abrasive, comprising the following components by weight: 1 part of polyurethane elastic material, 0.01 part of blue slurry, 9 parts of corundum, and 0.08 part of flame retardant.

[0040] The preparation method of above-mentioned sponge abrasive material, comprises the following steps:

[0041] Step 1: Heat the polyurethane elastic material to 60°C and mix it with blue pulp to obtain a mixture. The mixture is quantified by a high-speed pouring machine, stirred by a high-speed stirring device, and then flows into a composite stirring device;

[0042] Step 2: Heat the corundum to 80°C through a continuous heating furnace, and then continuously flow into the compound stirring device through the quantitative device;

[0043] Step 3: Stir the mixture of polyurethane elastic material and blue pulp flowing into the compound stirring device in step 1 and the corundum flowing into the compound stirring device evenly, so that the corundum is evenly distributed ...

Embodiment 3

[0046] Example 3 A sponge abrasive, comprising the following components in parts by weight: 0.999 parts of polyurethane elastic material, 0.005 parts of green slurry, 5 parts of corundum, and 0.05 parts of flame retardant.

[0047] The preparation method of above-mentioned sponge abrasive material, comprises the following steps:

[0048] Step 1: Heat the polyurethane elastic material to 50°C, mix green pulp and flame retardant to obtain a mixture, the mixture is quantified by a high-speed pouring machine, stirred by a high-speed stirring device, and then flows into a compound stirring device;

[0049] Step 2: Heat the corundum to 60°C through a continuous heating furnace, and then continuously flow into the compound stirring device through the quantitative device;

[0050] Step 3: Mix the mixture of polyurethane elastic material and green slurry flowing into the compound stirring device in step 1 and the corundum flowing into the compound stirring device evenly, so that the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com