Monitoring system of industrial robot

An industrial robot and monitoring system technology, applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of customer loss for power outage maintenance, rising labor costs, limited detection frequency and the number of inspectors, etc., to avoid errors report, improve accuracy, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

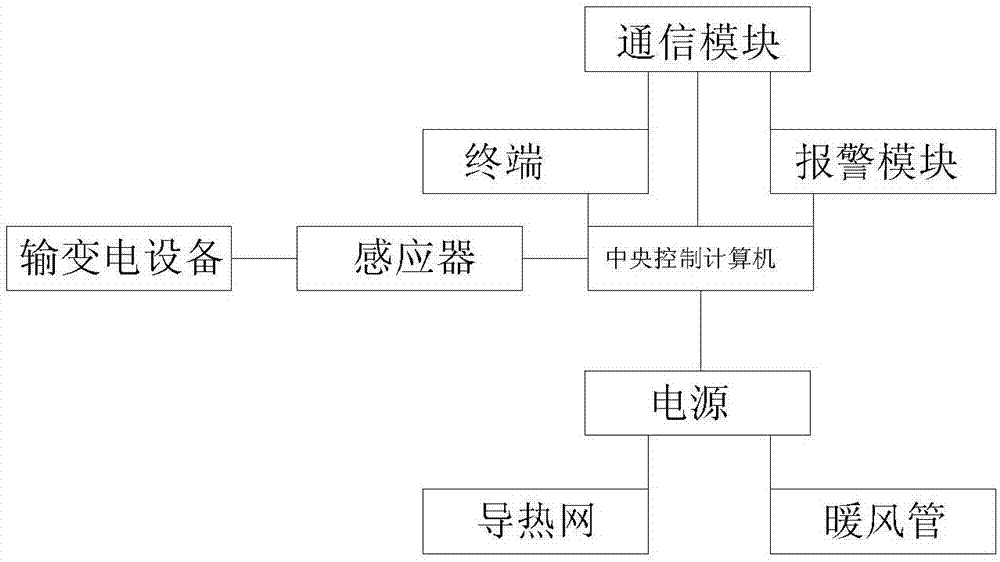

[0019] Such as figure 1 The innovation of the industrial robot monitoring system shown is that it includes a heating module, an inductor, a communication module, a central control computer, a terminal, and an alarm module; the heating module includes a heat conduction network uniformly arranged on the inner wall of the power transmission and transformation equipment , warm air pipe and power supply for providing electricity, the power supply is connected to the heat conduction forget and warm air pipe, the sensor is used to collect its working index parameters, the communication module is used to transmit the working index parameters processed by the controller, and the central control computer is used To monitor the working status of the power transmission and transformation equipment, the terminal is used to query the monitoring results, and the alarm modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com