Ultraviolet-curing adhesive with thermally induced self-healing property based on stepwise polymerization mechanism

A step-by-step polymerization, ultraviolet light technology, used in non-polymer organic compound adhesives, adhesives, etc., can solve problems such as microscopic cracks and bonding failures, avoid internal stress concentration, reliable bonding performance, and a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and comparative example

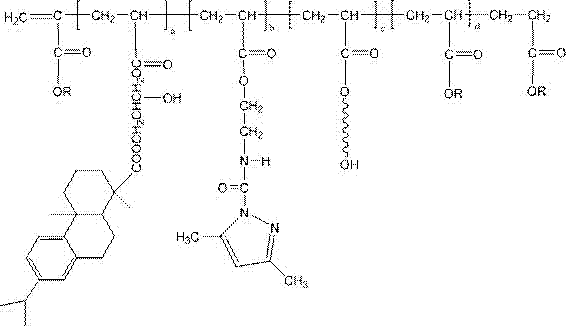

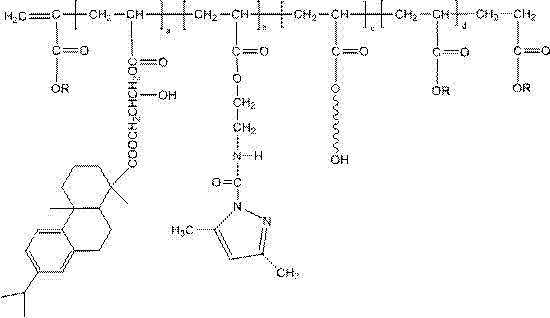

[0026] ①Synthesis of (meth)acrylate random prepolymer

[0027] Add (meth)acrylate viscous monomer, internal polymer monomer, functional monomer, rosin acrylate, blocked isocyanate acrylate and photoinitiator into the three-necked flask in proportion, start stirring at the same time, and purge with high-purity nitrogen solution for 30 minutes until the photoinitiator is completely dissolved, with a light intensity of 0.5 mW / cm 2 The solution is irradiated with ultraviolet light for 30-60s to obtain (meth)acrylate random prepolymer.

[0028] ②Add the multifunctional (meth)acrylate crosslinking agent and photoinitiator in proportion to the above-mentioned (meth)acrylate random prepolymer in sequence, stir and mix evenly to obtain the finished product.

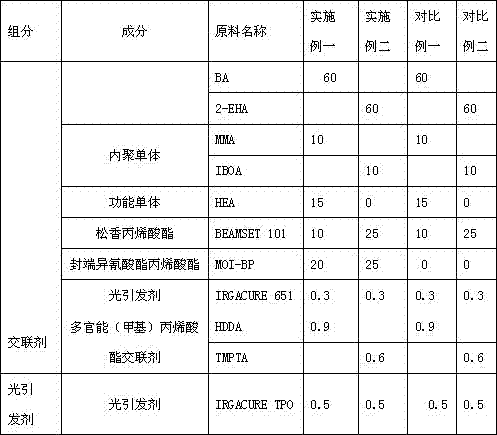

[0029] Table 1: Raw material proportioning of embodiment and comparative example

[0030]

[0031]Description: The raw materials used in the test are EA-ethyl acrylate, BA-n-butyl acrylate, 2-EHA-isooctyl acrylate, MMA-methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com