Dry type flavor substance feeding device of beer crafting fermentation tank

A technology of flavoring substances and feeding devices, which is applied in the field of beer manufacturing, can solve the problems of affecting the fermentation process of wine body, the emission of carbon dioxide and wine body, and the inability to adapt to the requirements of craft beer technology, so as to achieve safe operation and prevent the leakage of alcohol Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

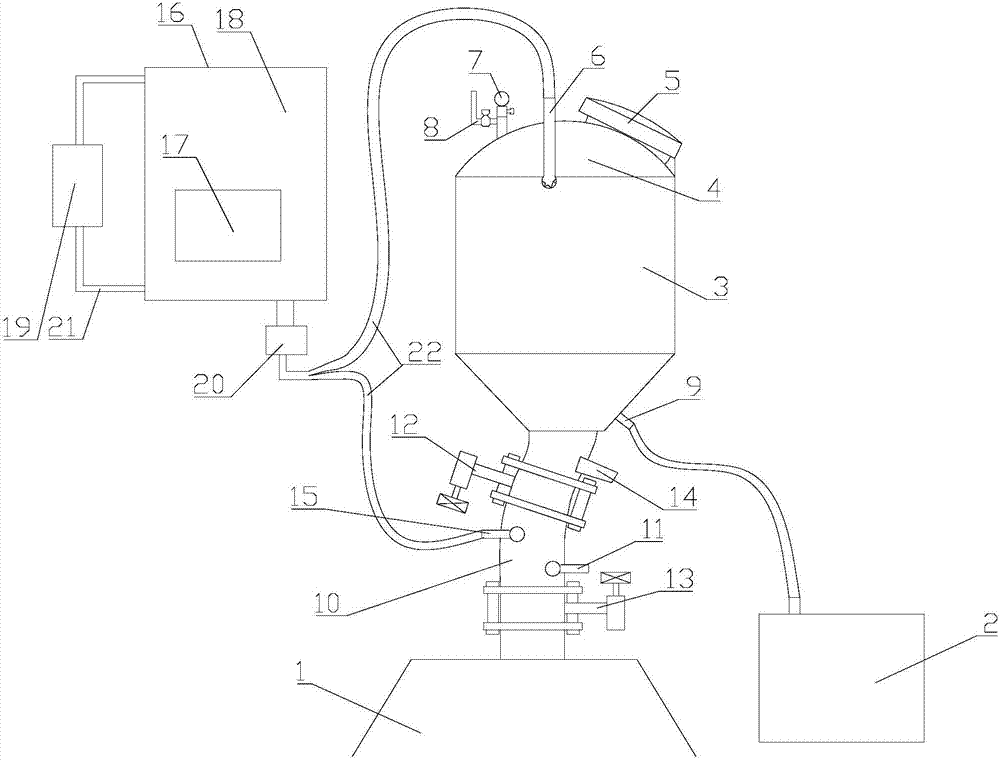

[0020] In order to better illustrate and set forth the content of the present invention, the following will be described in conjunction with schematic diagrams and implementation examples: figure 1 As shown, the present invention provides a dry-type feeding device for flavor substances in a craft beer fermenter, which is arranged on the top of a craft fermenter 1, and a carbon dioxide system and a steam system 2 are provided outside the craft fermenter 1, including a storage container 3 and a CIP cleaning device 16, the top of the storage container 3 is provided with a circular head 4, and the top of the circular head 4 is respectively provided with a circular feeding port 5, a spherical tank washer 6, a pressure gauge 7 and a safety valve with an upward opening The discharge port 8; the bottom of the material storage container 3 is a conical structure and is provided with an air intake channel valve 9, which is connected to the intake air path of the carbon dioxide system and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com