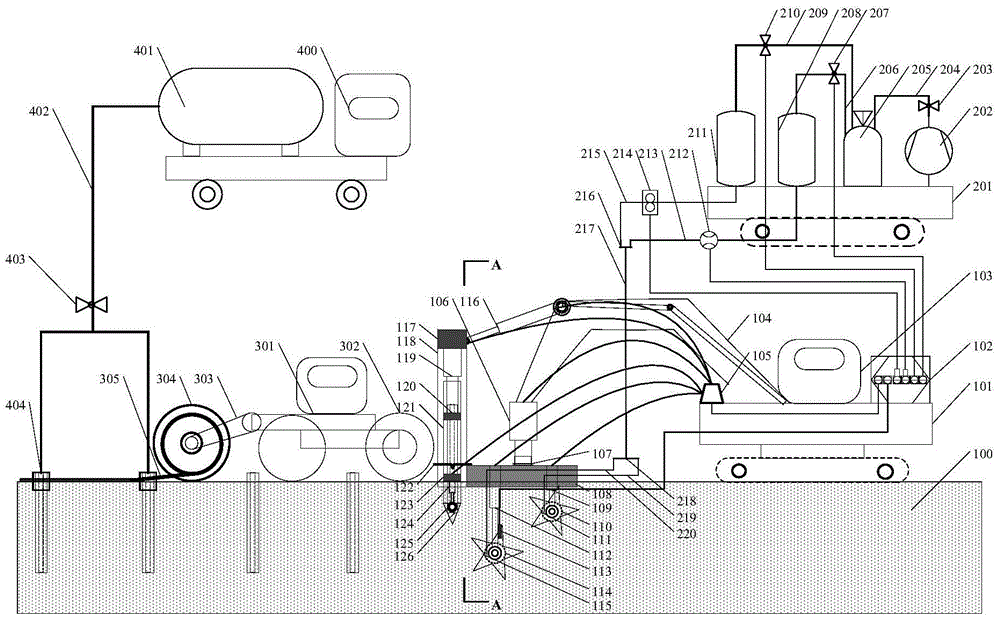

An in-situ carbonization and solidification treatment system for shallow soft foundations

A technology for weak foundation and solidification treatment, which is used in foundation structure engineering, soil protection, sheet pile walls, etc., and can solve problems such as increasing the amount and cost of foundation treatment, higher requirements for stabilization time, and insignificant increase in strength. , to achieve the effect of being less prone to failure, improving carbonization efficiency, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

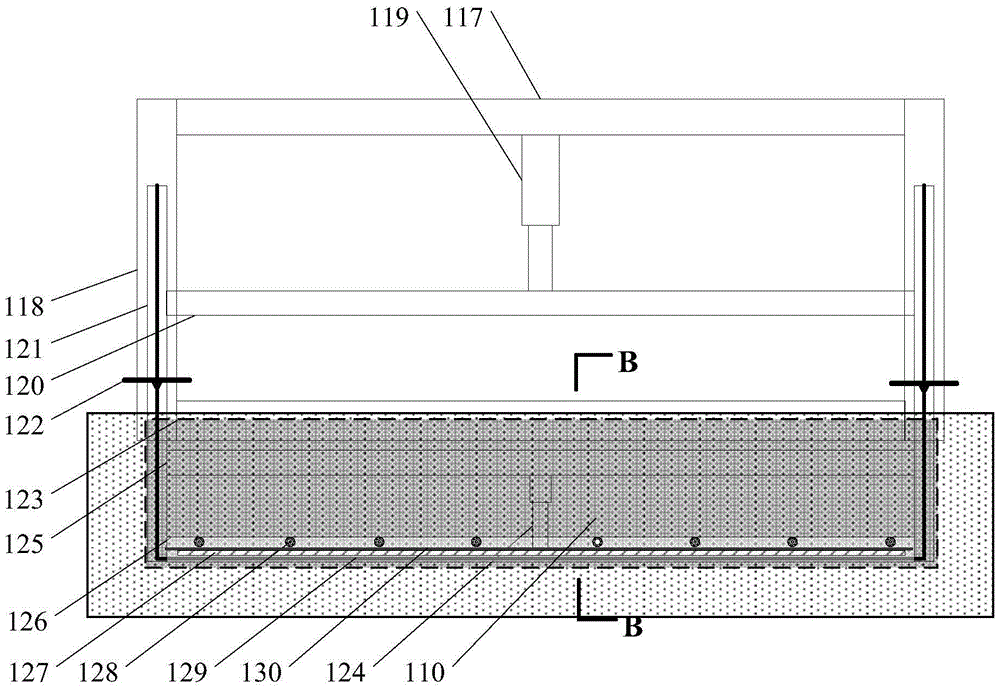

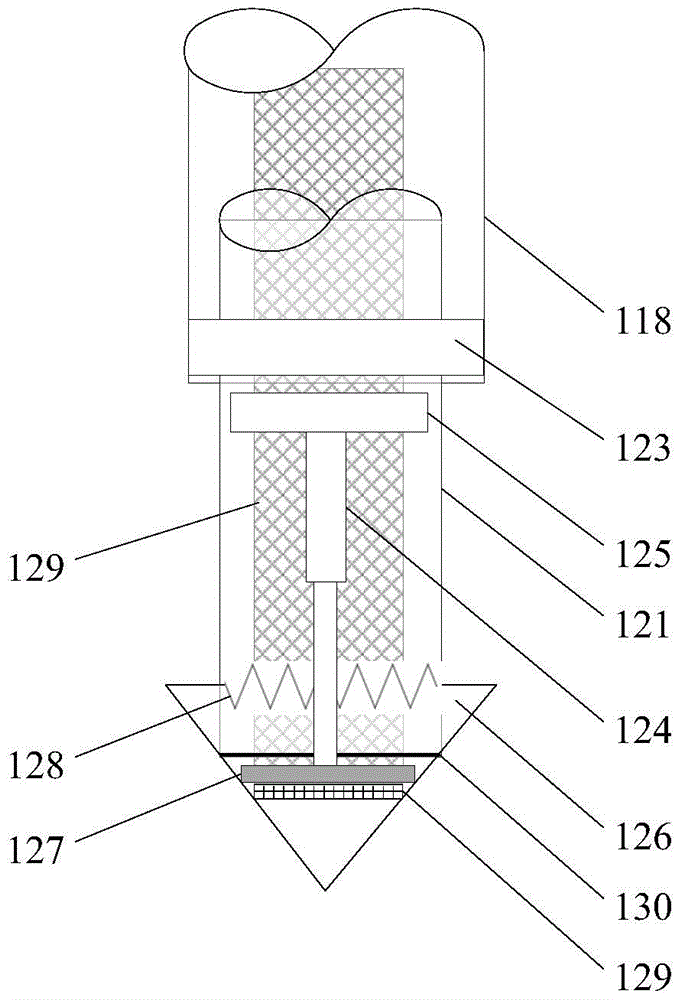

[0066] If the pretreated foundation soil 100 is sandy soil with a depth of 1.0m, the stirring radius of the first stirring device 110 and the second stirring device 114 is 0.3~0.5m, and the positive and negative rotation speeds of stirring are 15~25 r / min. The walking speed of the mixer 101 is 2.0~2.5 km / h, the mixing width is 3.0~3.5m, and the amount of curing agent is 300 kg / m 3 , when the test reading of the moisture content sensor 113 is less than 25%, when the first curing agent is selected as active magnesium oxide powder and the second curing agent is anhydrous calcium chloride powder, the delivery rate of the curing agent is 2.5~5.0 kg / s ; The delivery rate of the second curing agent is 0.05~0.1 kg / s.

[0067] The first stirring device 110 and the second stirring device 114 are first set to forward rotation to break the soil, and then reverse stirring when spraying the curing agent. After the on-site mixing of the pretreated foundation soil 100 is completed, the air-p...

Embodiment 2

[0070] If the pretreated foundation soil 100 is silt soil with a depth of 1.0 m, the stirring radius of the first stirring device 110 and the second stirring device 114 is 0.3 ~ 0.5 m, and the forward and reverse speeds of stirring are 15 ~ 25 r / min. The walking speed of type mixer 101 is 2.0~2.5 km / h, the mixing width is 3.0~3.5m, and the dosage of curing agent is 350 kg / m 3 When the first curing agent is selected as active magnesium oxide powder and calcium oxide powder (mass ratio is 3:1), the second curing agent is anhydrous calcium chloride powder, when the test reading of the moisture content sensor 113 is 25~30%, Then the delivery rate of the curing agent is 5.0-8.0 kg / s, and the delivery rate of the second curing agent is 0.05-0.1 kg / s.

[0071] The first stirring device 110 and the second stirring device 114 are first set to forward rotation to break the soil, and then reverse stirring when spraying the curing agent. After the on-site mixing of the pretreated foundat...

Embodiment 3

[0074] If the pretreated foundation soil 100 is silt with a depth of 1.0 m, the stirring radius of the first stirring device 110 and the second stirring device 114 is 0.3-0.5 m, and the forward and reverse rotation speeds of the stirring are 25-40 r / min. The walking speed of the mixer 101 is 2.0~2.5 km / h, the mixing width is 3.0~3.5m, and the amount of curing agent is 300 kg / m 3 When selecting the first curing agent to be activated magnesium oxide powder, the second curing agent to be anhydrous magnesium chloride powder, when the test reading of the moisture content sensor 113 is 30~35%, the delivery rate of the curing agent is 5.0~8.0 kg / s, The delivery rate of the second curing agent is 0.2~0.4 kg / s.

[0075] The first stirring device 110 and the second stirring device 114 are first set to forward rotation to break the soil, and then reverse stirring when spraying the curing agent. After the on-site mixing of the pretreated foundation soil 100 is completed, the air-permeabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com