Near-shore area three-sided combined cofferdam

A side combination and area technology, which is applied in the field of trilateral combined cofferdams in near-shore areas, can solve the problems of unguaranteed waterproofing and stability, difficult construction of steel sheet pile cofferdams, etc., and achieve the effect of improving waterproofness and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a three-side combined cofferdam in the nearshore area, which is obtained through the following method of construction, and the method includes the following steps:

[0026] S1: Install two rows of parallel outer steel pipe piles 5' on the bedrock, and install inner steel pipe piles 5 on the bedrock and the bottom cover layer of the riverbed, and the inner steel pipe piles 5 form a "U" shape with openings facing the bedrock arrangement;

[0027] S2: Set beam supports 6 on the outer steel pipe piles 5′ and inner steel pipe piles 5, respectively set inner guide frames 7 on the beam supports 6 outside each row of inner steel pipe piles 5, A "U"-shaped outer guide frame 7' is set between the outer steel pipe pile 5' and the inner steel pipe pile 5 on the girder 6, and the height of the girder 6 is higher than the height of the bottom cover concrete 4 to be poured;

[0028] S3: insert and drive steel sheet piles along the inner guide frame 7 between ...

Embodiment 2

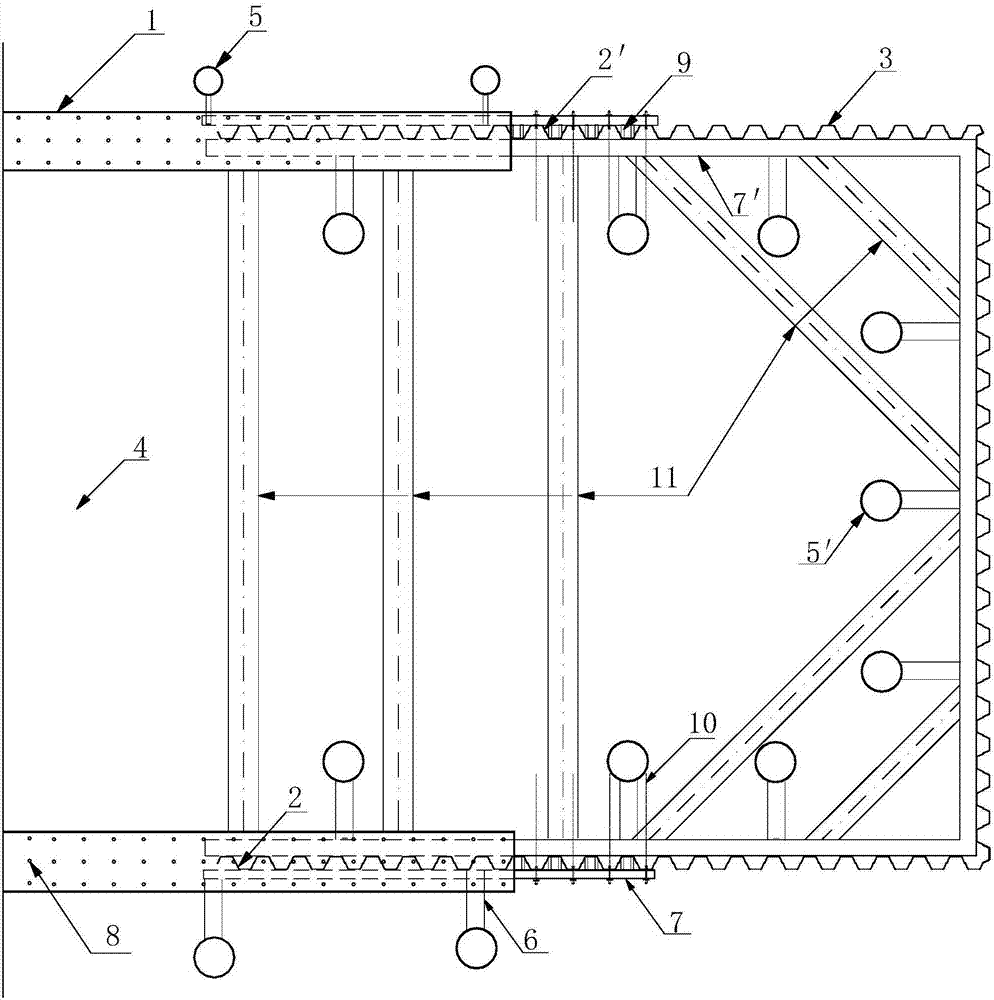

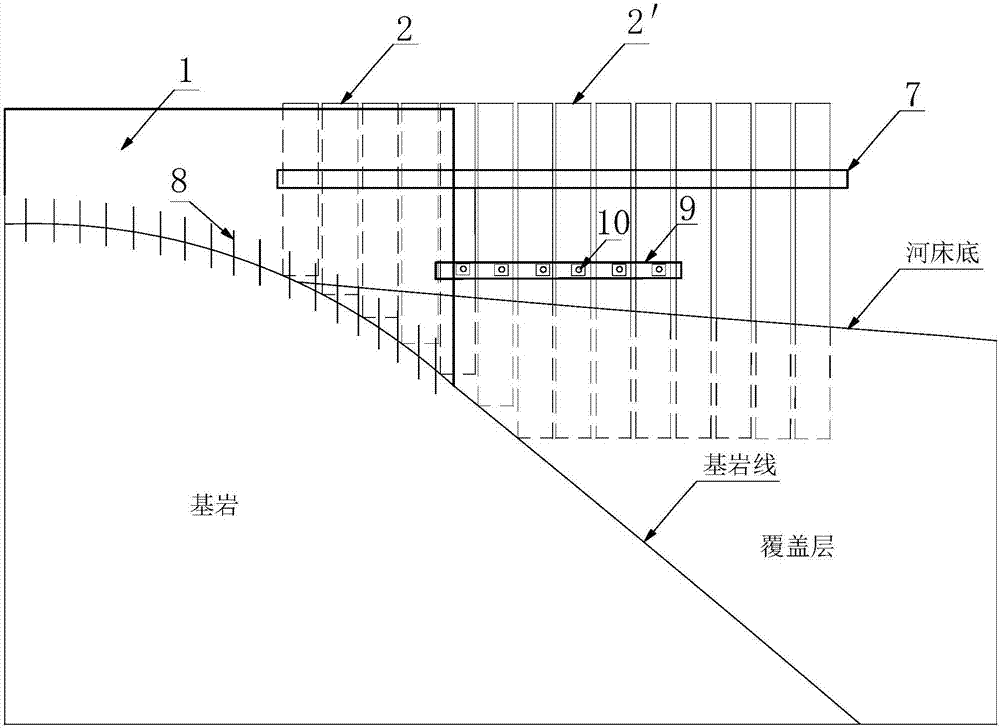

[0038] This embodiment provides a three-side combined cofferdam structure in the nearshore area, such as figure 1 or 2, including:

[0039] Two vertical cofferdams far away from the bank and a cofferdam along the river connecting the two vertical cofferdams parallel to the bank; The shallow buried area is embedded with concrete wall steel sheet pile 2, the shallow buried area steel sheet pile 2' inserted into the river bed bottom covering layer, and the cofferdam along the river is the deep buried area steel sheet pile 3 inserted into the river bed bottom covering layer, and the bottom of the cofferdam is sealed Concrete 4;

[0040] In the shallow buried area, there are several outer steel pipe piles 5 arranged side by side on the outer side of the steel sheet pile 2 embedded in the concrete wall. In the shallow buried area, the steel sheet pile 2 is embedded in the concrete wall, and the steel sheet pile 2' in the shallow buried area is inserted along and through the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com