Assembly-type cast-in-place concrete structure disassembly-free template pipe gallery

A technology for concrete structures and formwork-free dismantling, which is applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of uneven foundation resistance, unfavorable ecological environment protection, water-stop belt cracking, etc., and achieves improved construction. Speed and construction accuracy, the effect of reducing natural resource consumption and increasing construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

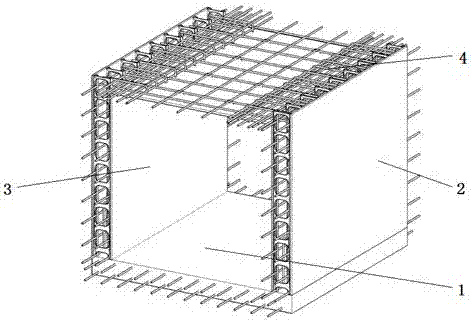

[0028] combine figure 1 , The first embodiment of the present invention includes a cast-in-place concrete base 1 , two prefabricated non-demolition formwork system wall panels 2 , 3 and a prefabricated non-demolition floor panel 4 .

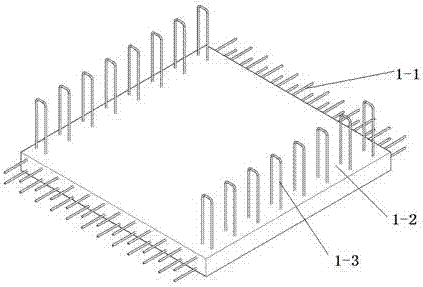

[0029] combine figure 2 , the cast-in-place concrete floor specifically includes bottom reinforcement 1-1, poured concrete layer 1-2 and reserved wall anchorage reinforcement 1-3 on both sides, and the wall anchorage reinforcement is preferably n-type.

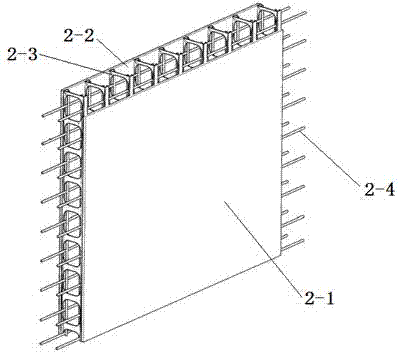

[0030] combine image 3 , the prefabricated no-demolition formwork system wall panel specifically includes a metal truss composed of section steel 2-3 and steel bars 2-4, a no-demolition formwork 2-2 installed on the outside of the metal truss, and a no-demolition formwork 2-1 installed on the inside of the metal truss . The demolition-free formwork is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com