Clean and efficient novel mining hydraulic excavator

A hydraulic excavator, high-efficiency technology, applied to mechanically driven excavators/dredgers, liquid separators, earth movers/shovels, etc., can solve the health hazards of excavator operators, pollute the surrounding environment, Noise pollution and other issues can be achieved to improve the working environment of workers, ensure personal safety, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

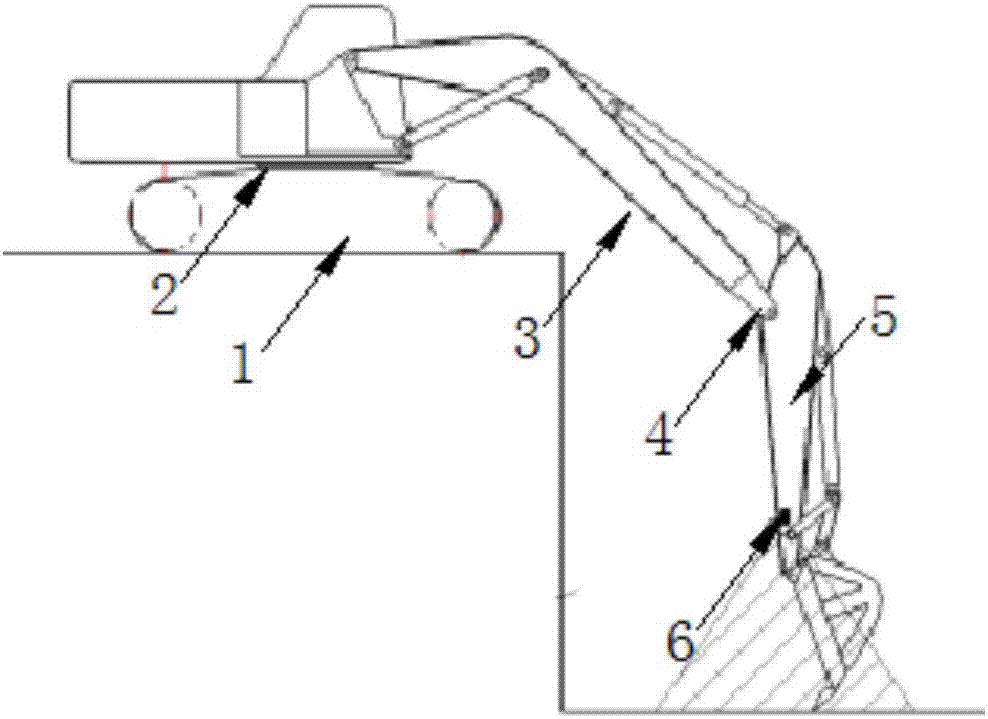

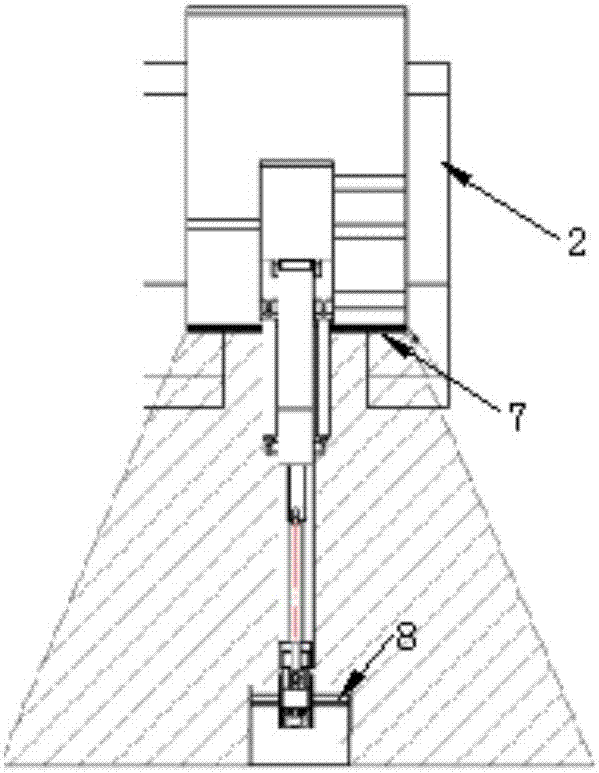

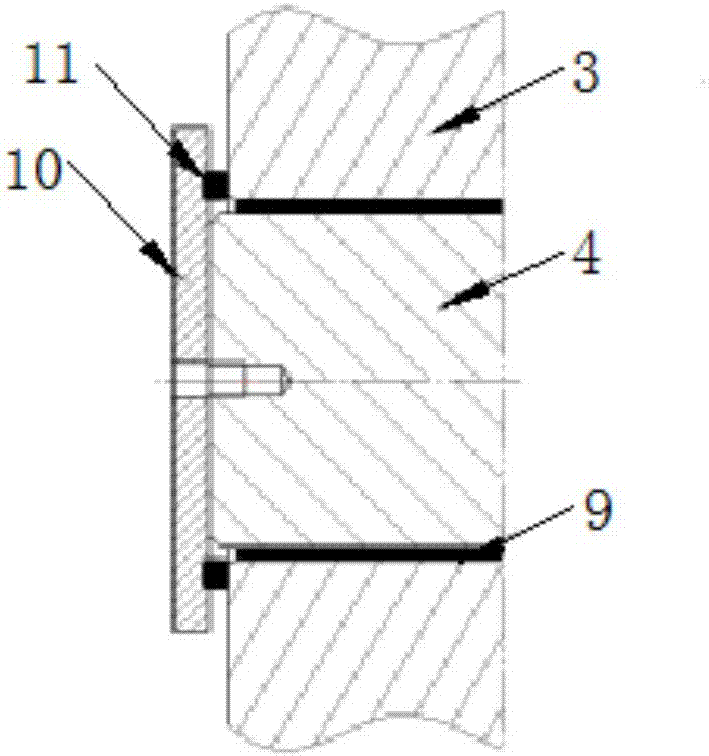

[0017] Example: such as Figure 1-3 As shown, a clean and high-efficiency new mining hydraulic excavator of the present invention includes a body 1, the body 1 includes a rotary platform 2 installed therein, and the body 1 is equipped with a driver's cab through the rotary platform 2, and the body 1 passes through the A boom 3 is movably installed in the cab inside, and a stick 5 is movably installed at the end of the boom 3 through the boom pin 4 , and a bushing 9 is nested at the connection between the outer end surface of the boom pin 4 and the boom 3 , A pin baffle 10 is fixedly inserted into the side end surface of the boom pin 4, and the pin baffle 10 is closely connected with the boom 3 through a retaining ring 11, and a bucket 8 is movably installed at the bottom of the arm 5, and the arm 5 The bucket nozzle group 6 is installed near the bucket 8 at the front end, and the bucket nozzle group 7 is fixedly installed on the beam of the rotary platform 2. The shaft sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com