Horizontal splicing method of built-in steel rib type shear wall

A shear wall and horizontal technology, applied to walls, building components, buildings, etc., can solve the problems of difficult control of precision, low construction efficiency, poor quality assurance, etc., achieve convenient and simple structure processing, improve construction efficiency, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

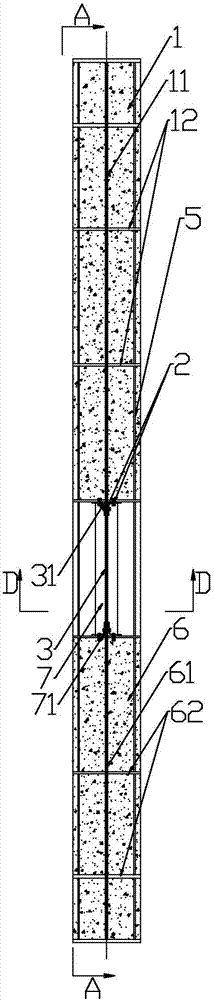

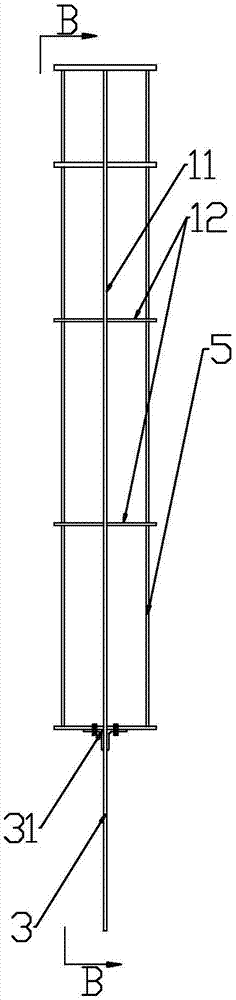

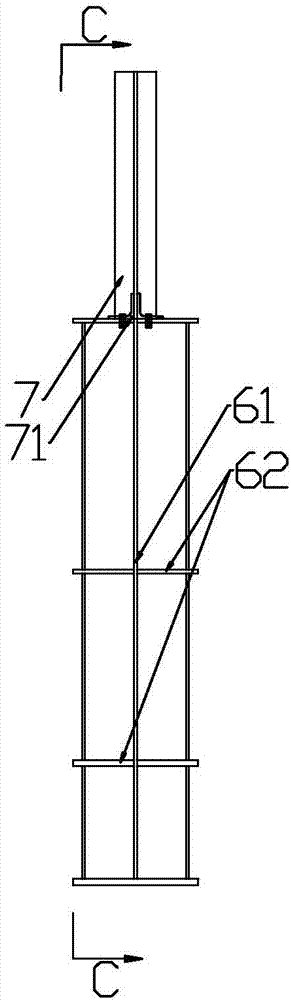

[0028] In this embodiment, a horizontal splicing method for embedded steel frame shear walls combines figure 1 with Figure 4 , Figure 5 , the combined wall includes an upper wall 1, a lower wall 6 and a middle web, the upper wall 1 and the lower wall 6 are provided with middle plates and ribs, and the ribs are arranged in multiples and installed on the middle plate; the middle The web is connected between the upper wall 1 and the lower wall 6, and is connected with the end ribs of the upper wall 1 and the end ribs of the lower wall 6 with angle steel, that is, the connection between the upper wall 1 and the lower wall is realized. After the horizontal docking of the wall body 6, the flat steel 5 is welded on the ribs of the docking part, and the concrete is cast in place, that is, the horizontal splicing of the embedded steel frame shear wall is completed.

[0029] In order to achieve more effects, the above scheme can also be added in the following way:

[0030] combine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com