Building 3D printer and building 3D printing method

A 3D printer and construction technology, which is applied in construction, building structure, and processing of building materials, etc., can solve the problems of limited printing height of 3D printing device, small size of 3D printing device, low work efficiency, etc., and achieve lightweight and lightweight , a wide range of applications, the effect of simplified construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

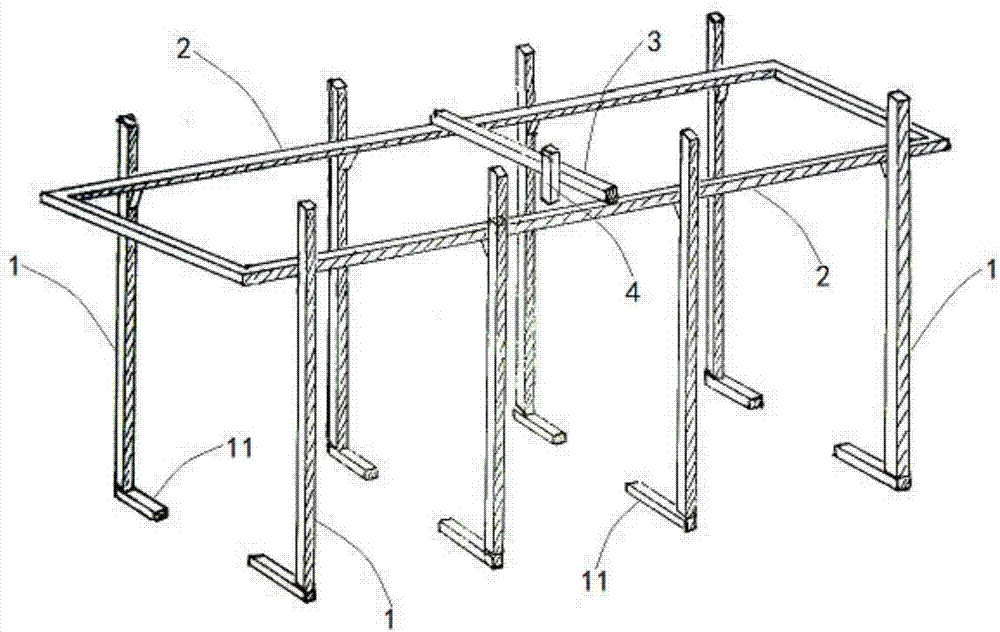

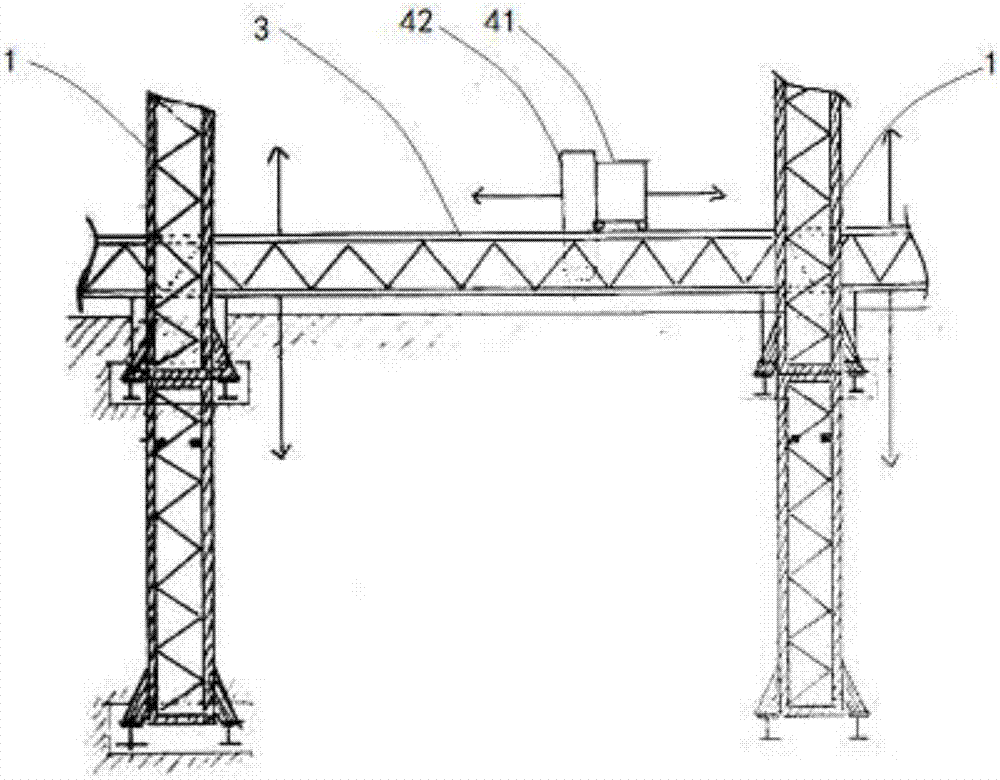

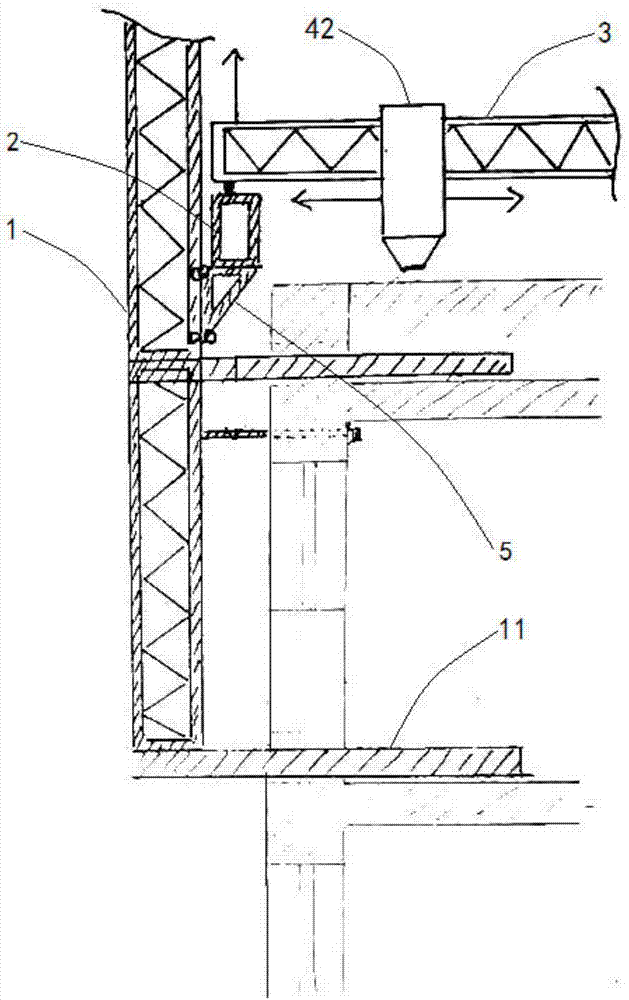

[0039] Such as figure 1 As shown, a construction 3D printer includes two sets of Z-axis pillars 1 , two X-axis beams 2 , Y-axis moving beams 3 and printing components 4 . The two groups of Z-axis pillars 1 are all arranged vertically and arranged oppositely. One side of the Z-axis pillars 1 is connected with a plurality of horizontally arranged racks 11, and the racks are plugged into the reserved parts on the wall. In the hole; two X-axis crossbeams 2 are arranged parallel to each other, and the X-axis crossbeam 2 is vertically arranged with the Z-axis pillar 1 and is slidably connected; the two ends of the Y-axis moving beam 3 are respectively connected to the two X-axis The axis beam 2 is slidingly connected; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com