Receiving Clamp, Component, Carrying System, And Components Of Receiving Clamp And Working Apparatus

A technology of working equipment and carrying system, applied in the field of accommodating clips, can solve the problems of complicated connection between the guide rod and the carrying system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

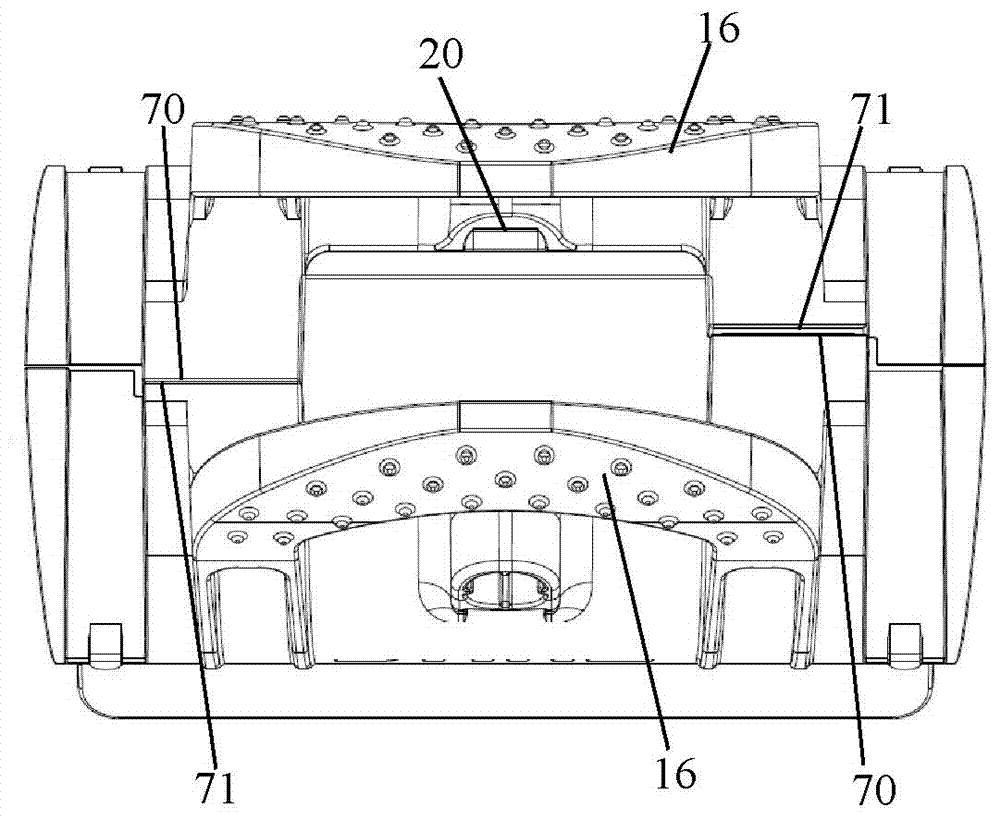

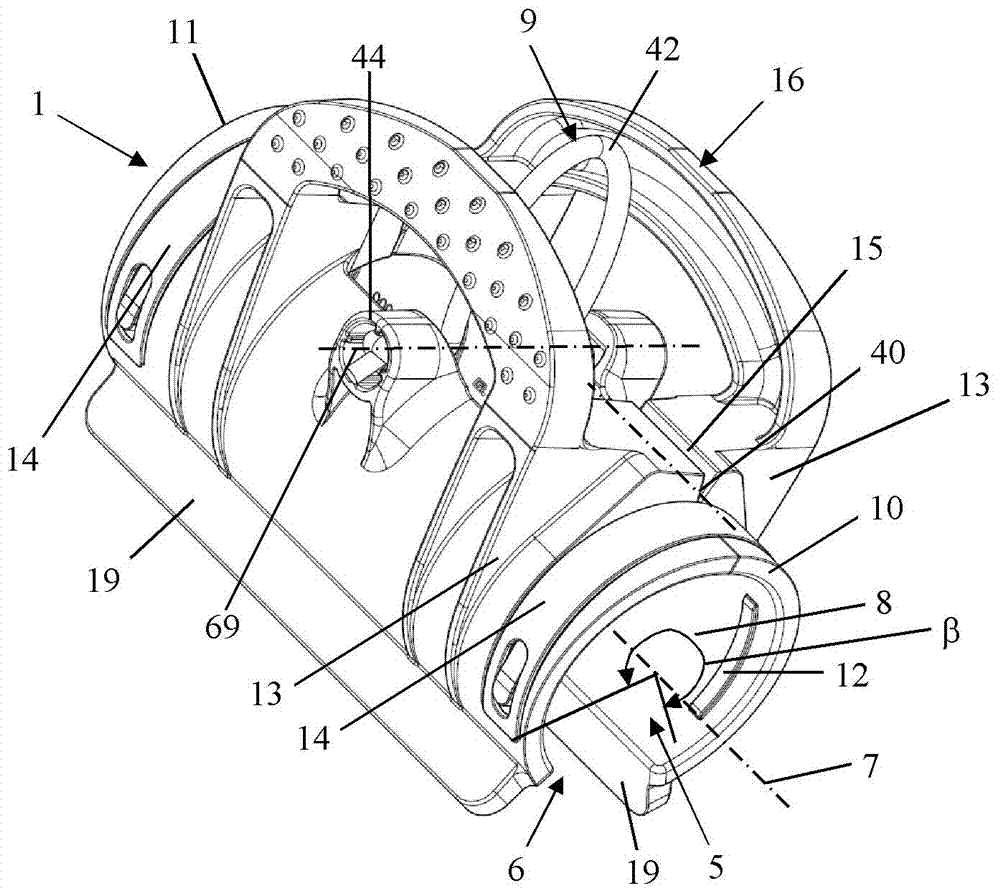

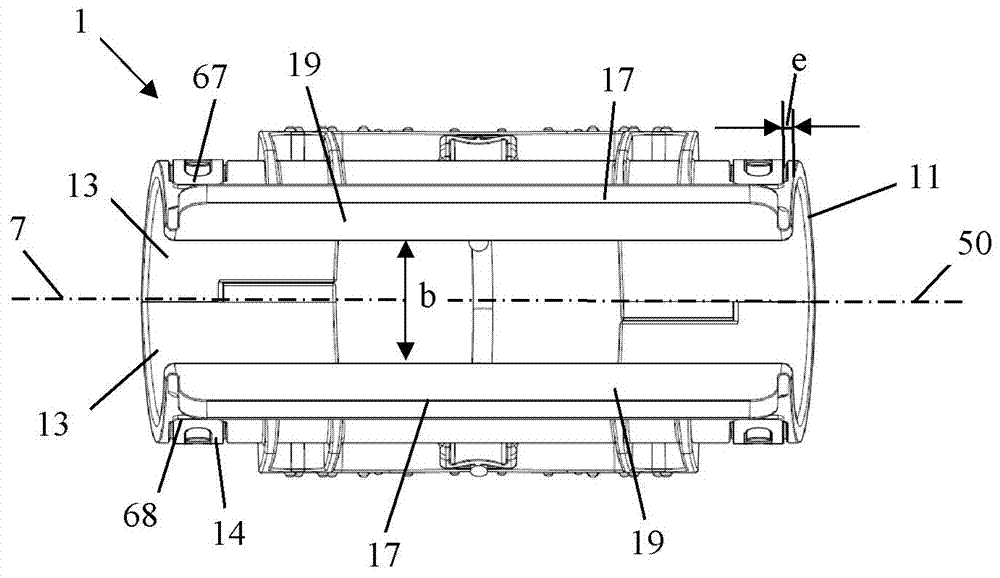

[0046] exist figure 1 An operator 21 is shown in , who uses the carrier system 3 on which the power tool 2 with the guide rod 18 is arranged. The power tool 2 can be, for example, a pruner, a free-cut cutter or another portable power tool 2 with a guide rod 18 . The carrier system 3 is designed to at least partially absorb the weight of the work implement 2 via the shoulders and / or the torso and / or the buttocks of the operator 21 . The carrying system 3 advantageously comprises a carrying plate 22 carried by the operator 21 by means of a waist belt 25 , a back belt 24 and two shoulder belts 23 . The carrying arm 4 is fixed on the carrying plate 22 . The carrying arm 4 protrudes upwards from the operator 21 in the direction of the guide rod 18 of the power tool 2 . In this exemplary embodiment, the first end 27 of the connecting piece 29 is fastened at the protruding end of the carrier arm 4 . The connection piece 29 is in particular flexurally flexible. In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com