Automatic solder mask exposure frame module and exposure machine

A technology of exposure tables and frame molds, which is applied in microlithography exposure equipment, photolithography exposure devices, optics, etc., and can solve problems affecting product quality, low efficiency, and insufficient adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

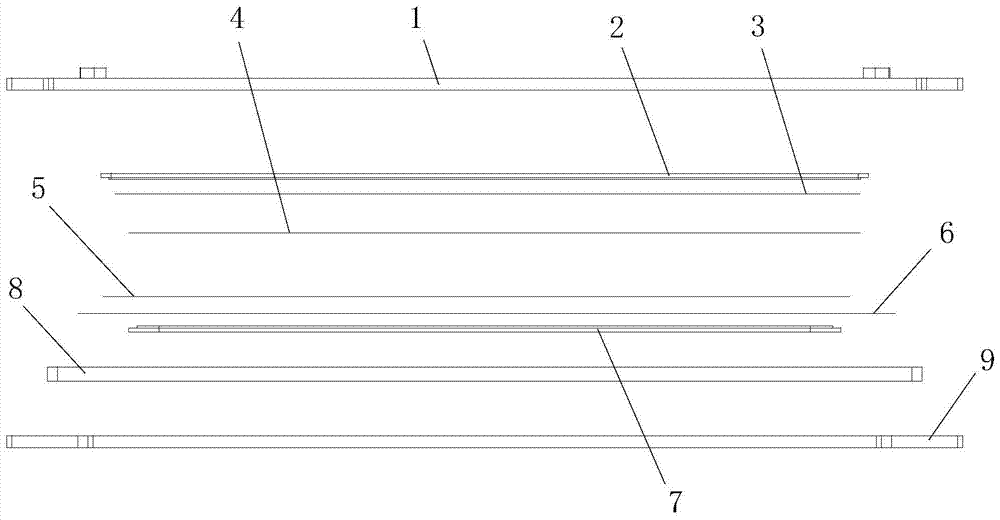

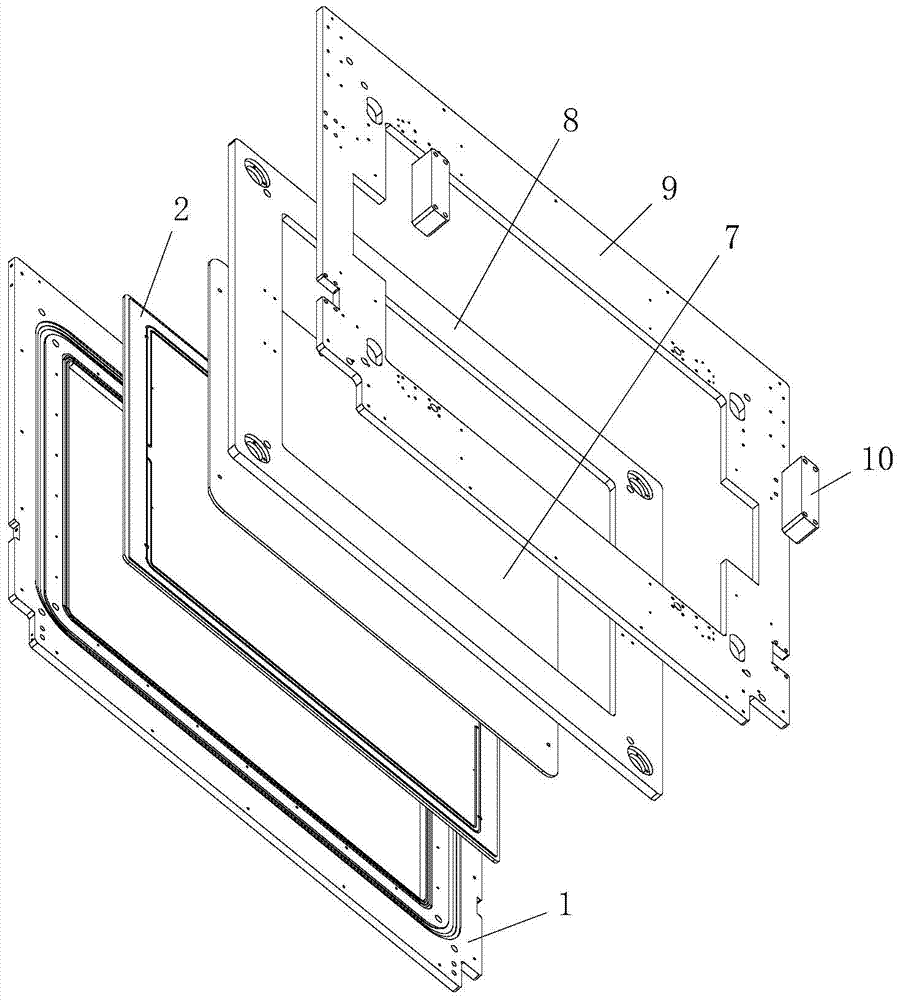

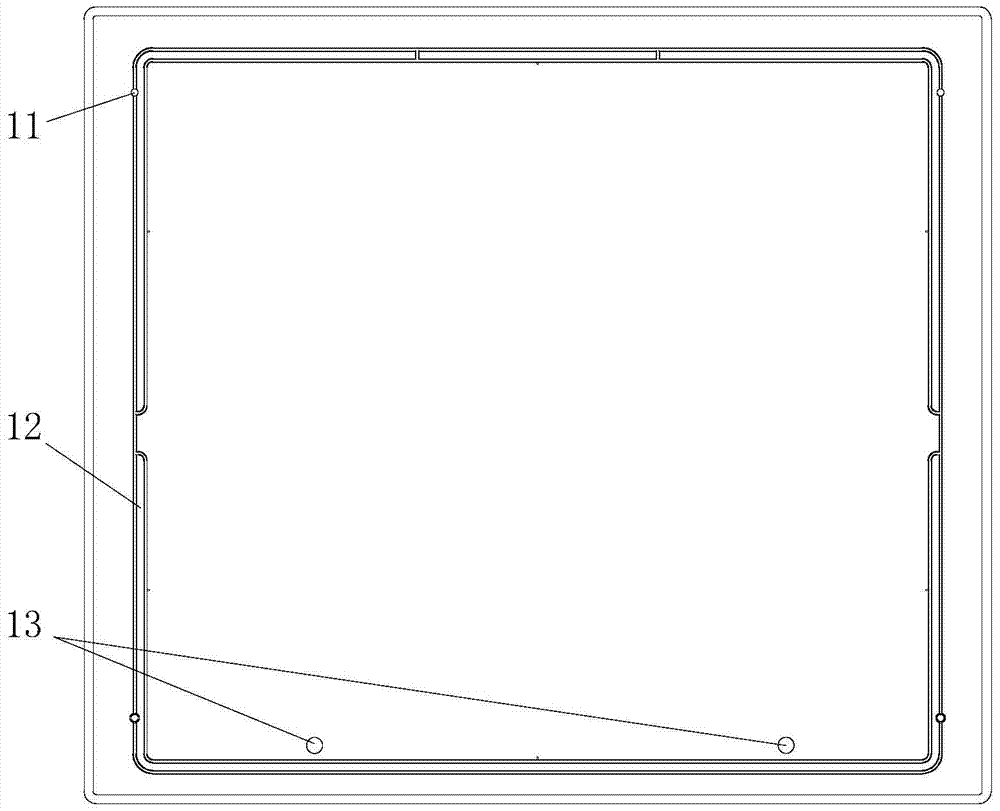

[0029] Embodiment 1, for automatic double-sided exposure, refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the automatic solder mask exposure table frame module and the exposure machine, the table frame module is installed in the host 14 of the automatic solder mask exposure machine, the host 14 is connected with a control mechanism 15, the host 14 has an alignment platform 18, an optical alignment Device 17 (such as a CCD lens), frame module 16, exposure chamber 20, exposure light source and power supply mechanism, frame module 16 is installed in the host 14, and the transfer mechanism in the host 14 exposes the frame module 16 The transfer inside and outside the chamber 20; the exposure light source exposes the circuit boards in the frame module transferred to the exposure chamber; the alignment platform 18 and the optical alignment device 17 cooperate to align the circuit boards in the frame module; The table frame module includes an upper frame 1, ...

Embodiment 2

[0044] Embodiment 2 is used for automatic single-sided exposure. The difference from automatic double-sided exposure is that only the lower glass 7 and the lower negative film 5 need to be removed, and the step of alignment between the circuit board 4 and the lower negative film 5 is omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com