Vacuum pipe clamp valve applied to vacuum system and control method of vacuum pipe clamp valve

A vacuum system and vacuum tube technology, applied in the direction of diaphragm valves, valve devices, engine components, etc., to achieve the effect of ensuring sealing, ensuring normal operation, and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

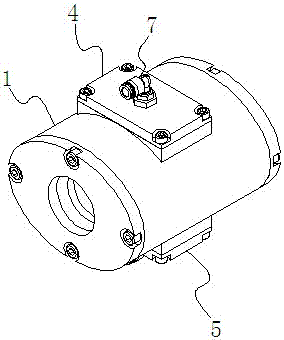

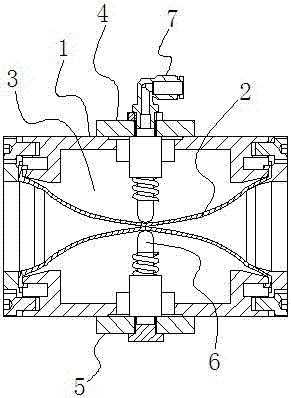

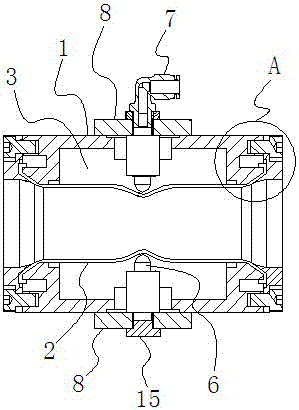

[0029] Example: such as Figure 1 to Figure 3 As shown, a vacuum pipe pinch valve applied to a vacuum system includes a pinch valve pipe body 1 and a sleeve 2 arranged inside the pinch valve pipe body 1, between the inner wall of the pinch valve pipe body 1 and the outer wall of the sleeve 2 Set as a sealed space 3, on the outer side of the pinch valve body 1, there are also elastic pressing block device one 4 and elastic pressing block device two 5, elastic pressing block device one 4 and elastic pressing block device two 5 The pressure block 6 extends into the sealed space 3 and clamps the sleeve 2 closed by the pressure block 6 in the elastic pressure block device 1 and the pressure block 6 in the elastic pressure block device 2, and the sleeve 2 is clamped in the pinch valve body 1 The outer part is also provided with a vacuum tube interface 7 for evacuating the sealed space. When the sealed space 3 is evacuated through the vacuum tube interface 7, the pressure block 6 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com