Model bracket attack angle mechanism

An angle-of-attack mechanism and model technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of not being able to obtain the conditions of the angle of attack and the speed of the angle of attack, and achieve the effect of flexible adjustment and guaranteed cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

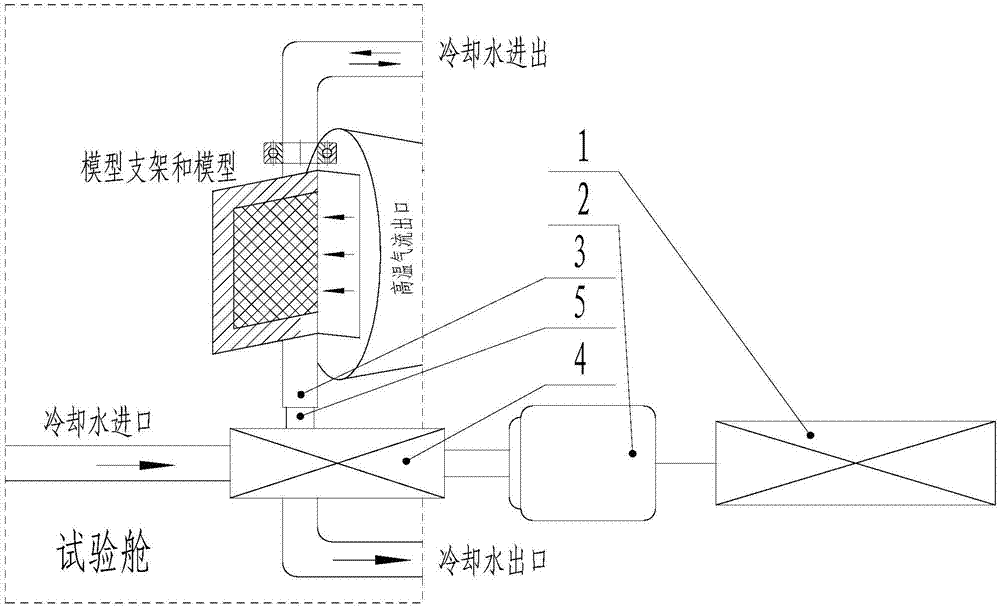

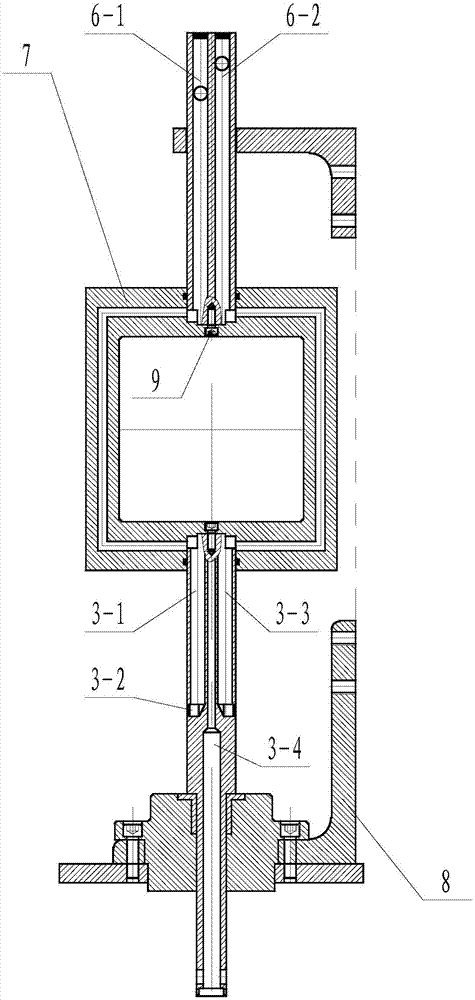

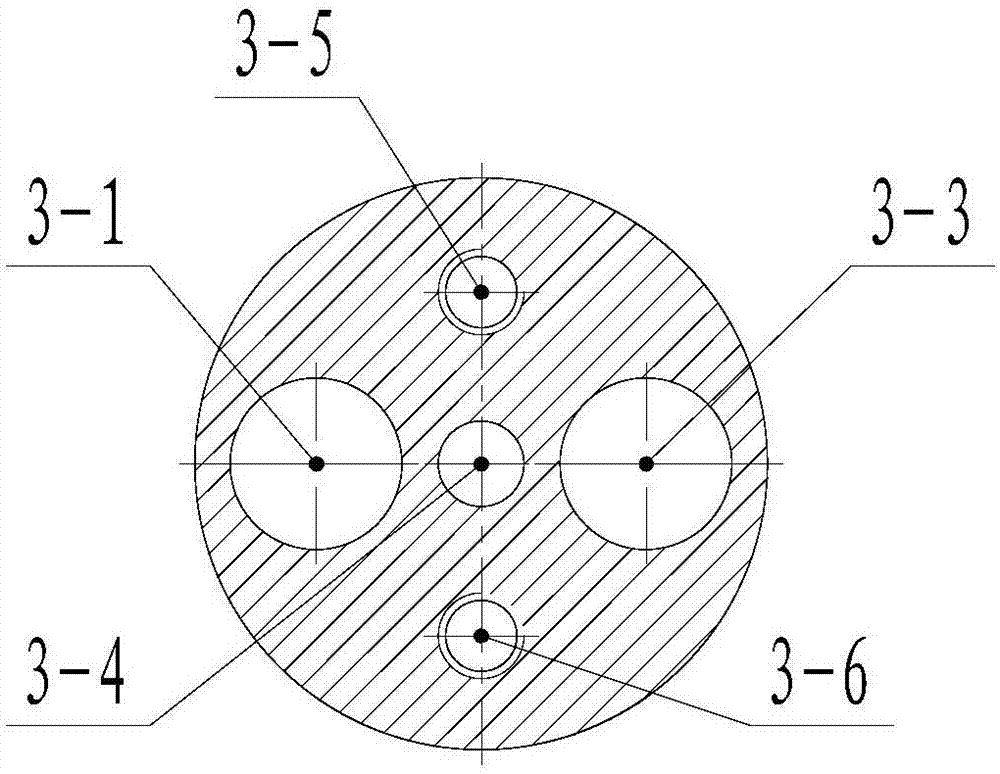

[0033] Such as figure 1 As shown, the angle-of-attack mechanism of the model support is mainly composed of a controller 1, a servo motor 2, a lower transmission shaft 3, an upper transmission shaft 6, a water-cooled reducer 4, an angle sensor 5 and a bracket 7. The controller 1 drives the servo motor 2 to rotate, and the water-cooled reducer 4 decelerates to make the water-cooled lower transmission shaft 3 drive the bracket 7 to rotate, and the angle sensor 5 feeds back the angle signal of the bracket 7 rotation to the controller. The controller 1 adopts closed-loop feedback control technology according to the signal of the angle sensor 5, and can accurately change the attack angle of the model support and the change speed of the attack angle.

[0034] The support 7 is a rectangular block, the upper surface of the middle part is a groove, the test model is inside the groove, and the heat insulating material is placed at the bottom of the groove to avoid the influence of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com