Permanent magnet synchronous direct-driven motor bearing structure of the stirring industry

A permanent magnet synchronous and motor shaft technology, which is applied in the direction of electric components, casings/covers/supports, electrical components, etc., can solve the problems of accelerated gear wear, shortened life of the reducer, and low overall efficiency, and optimize the bearing structure , optimize the force condition, optimize the effect of the bearing span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

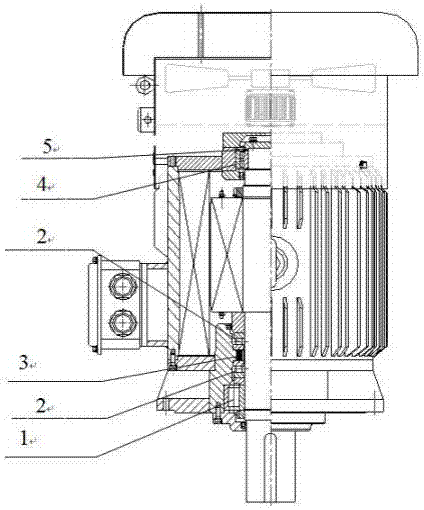

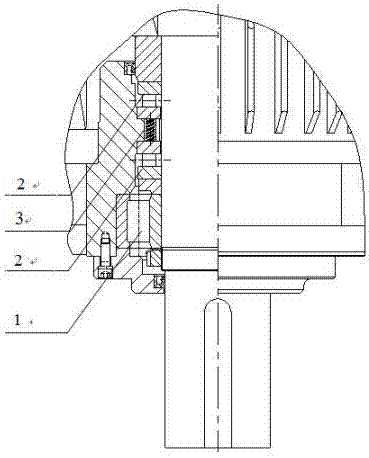

[0026] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides a bearing structure for permanent magnet synchronous direct drive motors in the stirring industry. The bearing structure includes a shaft end bearing and a tail bearing. The shaft end bearing is arranged at one end of the motor shaft extension, and the tail The bearing is located at the tail of the motor.

[0027] The shaft extension end bearing includes a set of cylindrical roller bearing 1 and two sets of cylindrical roller thrust bearings 2. The cylindrical roller bearing 1 and cylindrical roller thrust bearing 2 are arranged in sequence along the motor shaft extension end to the motor tail. An adjustment spring 3 is provided between the two sets of cylindrical roller thrust bearings 2, and the two sets of cylindrical roller thrust bearings 2 are arranged symmetrically relative to the adjustment spring 3; the adjustment springs.

[0028] The tail bearing includes a set of self-alig...

Embodiment 2

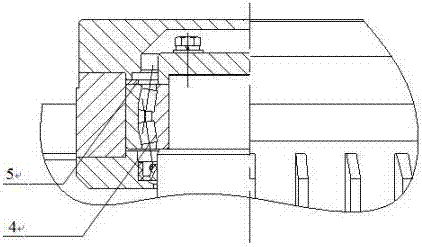

[0032] Such as figure 1 , figure 2 with Figure 4 As shown, the present invention provides a bearing structure for permanent magnet synchronous direct drive motors in the stirring industry. The bearing structure includes a shaft end bearing and a tail bearing. The shaft end bearing is arranged at one end of the motor shaft extension, and the tail The bearing is located at the tail of the motor.

[0033] The shaft extension end bearing includes a set of cylindrical roller bearing 1 and two sets of cylindrical roller thrust bearings 2. The cylindrical roller bearing 1 and cylindrical roller thrust bearing 2 are arranged in sequence along the motor shaft extension end to the motor tail. An adjustment spring 3 is provided between the two sets of cylindrical roller thrust bearings 2, and the two sets of cylindrical roller thrust bearings 2 are arranged symmetrically relative to the adjustment spring 3; the adjustment springs.

[0034] The tail bearing includes a set of self-ali...

Embodiment 3

[0038] Such as figure 1 , figure 2 with Figure 5 As shown, the present invention provides a bearing structure for permanent magnet synchronous direct drive motors in the stirring industry. The bearing structure includes a shaft end bearing and a tail bearing. The shaft end bearing is arranged at one end of the motor shaft extension, and the tail The bearing is located at the tail of the motor.

[0039] The shaft extension end bearing includes a set of cylindrical roller bearing 1 and two sets of cylindrical roller thrust bearings 2. The cylindrical roller bearing 1 and cylindrical roller thrust bearing 2 are arranged in sequence along the motor shaft extension end to the motor tail. An adjustment spring 3 is provided between the two sets of cylindrical roller thrust bearings 2, and the two sets of cylindrical roller thrust bearings 2 are arranged symmetrically relative to the adjustment spring 3; the adjustment springs.

[0040] The tail bearing includes a set of self-ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com