Crushing device having vibration reduction function

A technology of crushing device and function, applied in the field of scrap steel processing and recycling, can solve problems such as affecting the working environment, noise pollution, serious problems, etc., and achieve the effect of optimizing the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution will be described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

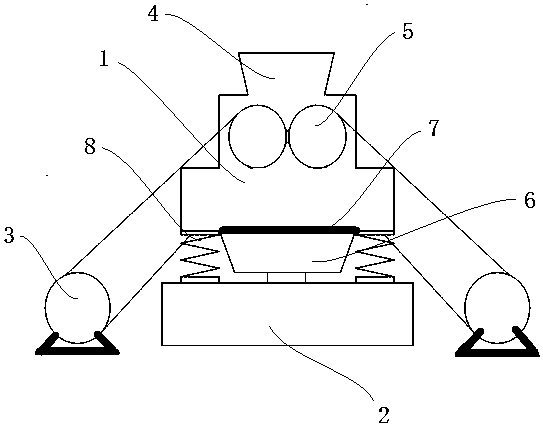

[0016] Such as figure 1 As shown, a crushing device with a vibration damping function includes a crushing box 1, a machine base 2 and a drive motor 3, the crushing box 1 is arranged above the machine base 2, and the top of the crushing box 1 is provided with a feed Bin 4, the inside of the crushing box 1 is provided with a pair of roller shafts 5, and the pair of roller shafts 5 are provided with several meshing blades refined from high alloy, and the pair of roller shafts 5 are connected with the drive motor 3 through a transmission mechanism connected, the bottom end of the crushing box 1 is provided with a discharge bin 6, the connection between the crushing box 1 and the discharge bin 6 is provided with a filter screen 7, and the crushing box 1 and the base 2 are installed with a Two spring shock a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com