Linear motion platform with ultrasonic-assisted friction overcoming function

A linear motion, ultrasonic-assisted technology, applied in the field of motion platforms, can solve problems such as difficult to establish high-precision friction models, complex compensation control methods, etc., and achieve the effect of simple structure, high positioning accuracy, and compact platform design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

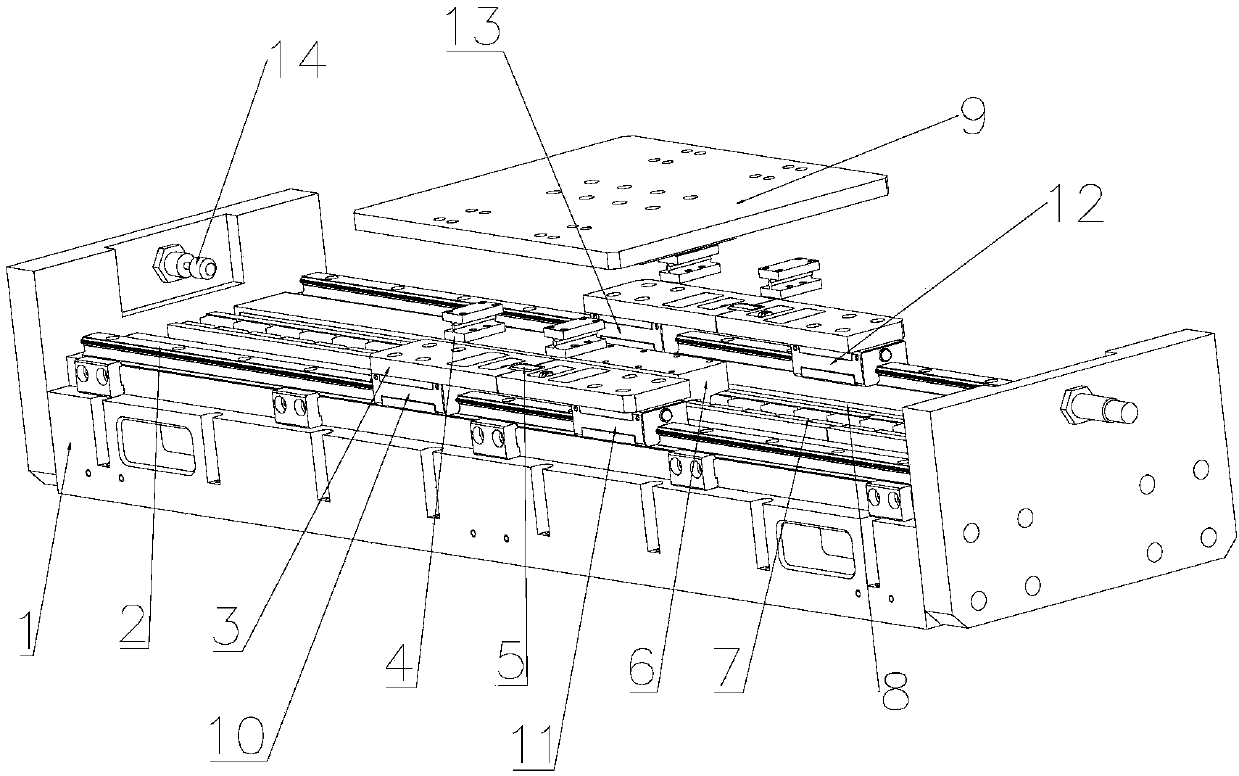

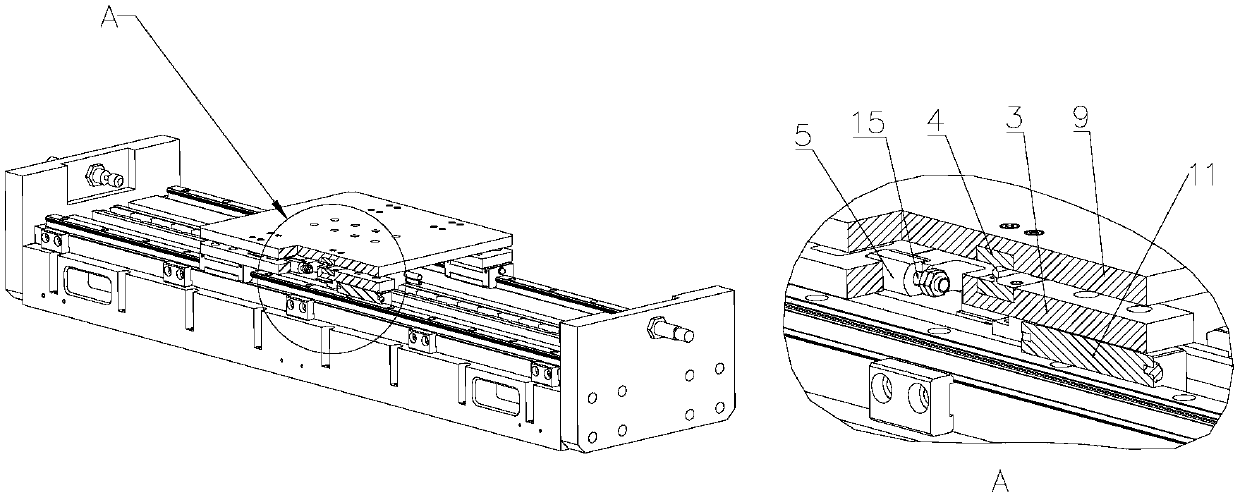

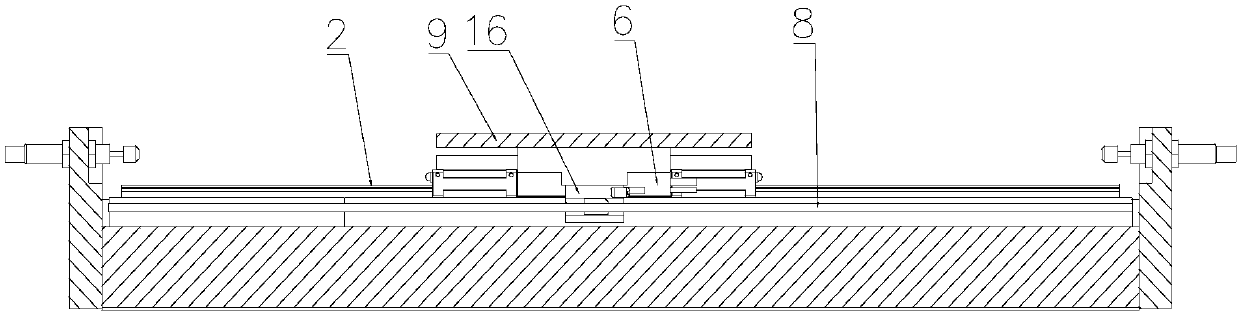

[0023] The accompanying drawings are for illustrative purposes only, and should not be construed as limitations on this patent; in order to better illustrate this embodiment, certain components in the accompanying drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art It is understandable that some well-known structures and descriptions thereof may be omitted in the drawings. The positional relationship described in the drawings is for illustrative purposes only, and should not be construed as a limitation on this patent.

[0024] Such as Figure 1-3 As shown, the ultrasonic-assisted friction-overcoming linear motion platform includes a machine base 1, which carries all structures. The linear guide rail 2 is installed on the machine base. The linear motor driver is composed of a linear motor mover 6 and a linear motor stator 7 . Wherein, the linear motor mover 6 can apply a driving force to the workta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com