Secondary air pump driven by brushless motor

A technology of brushless motors and secondary air, which is applied in the direction of electrical components, electric components, and parts of pumping devices for elastic fluids, etc. It can solve problems such as poor sealing effect, deviation of installation dimensions, and inconvenient assembly and molding. Achieve the effects of high air volume control stability, elimination of frictional resistance, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

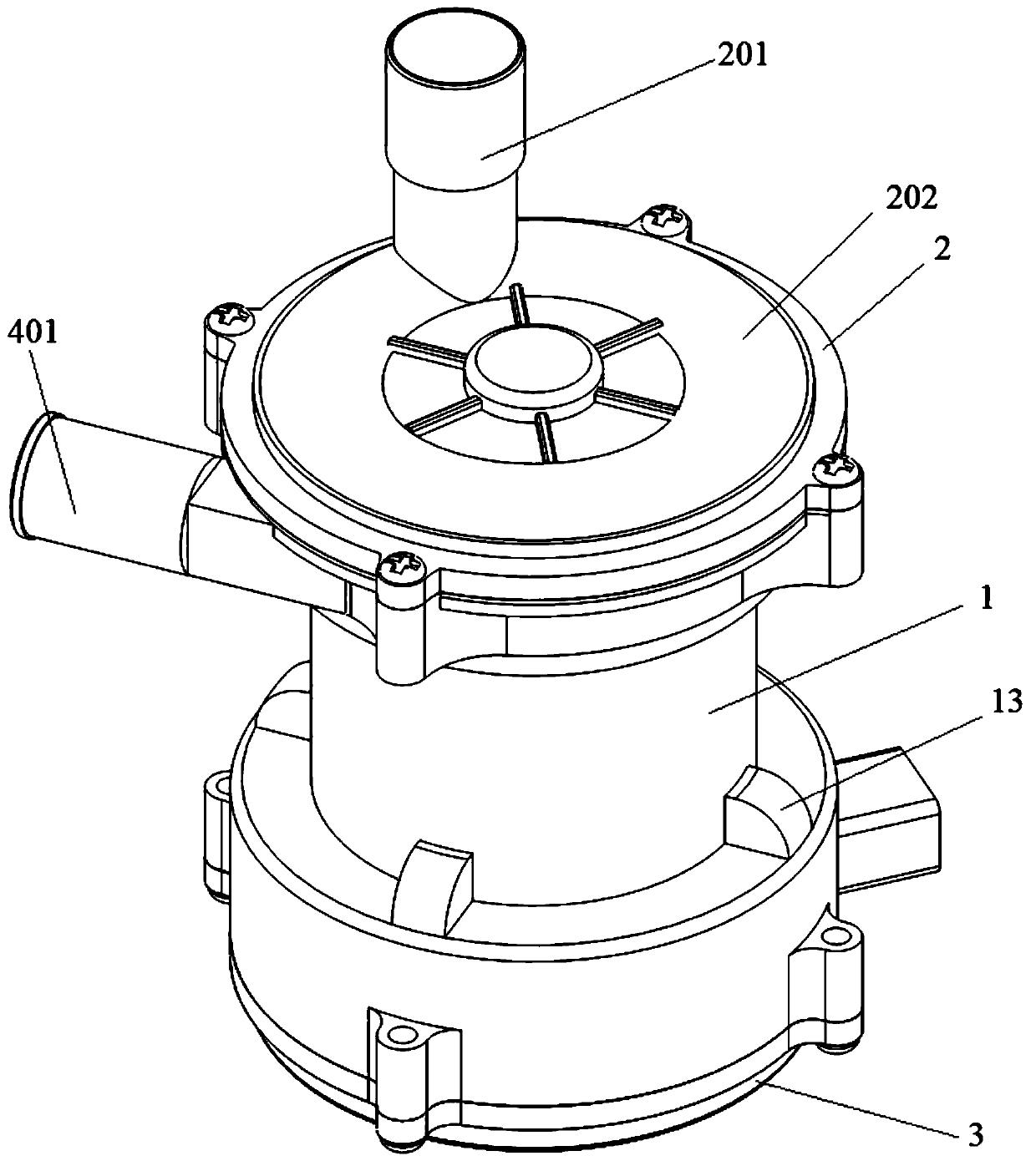

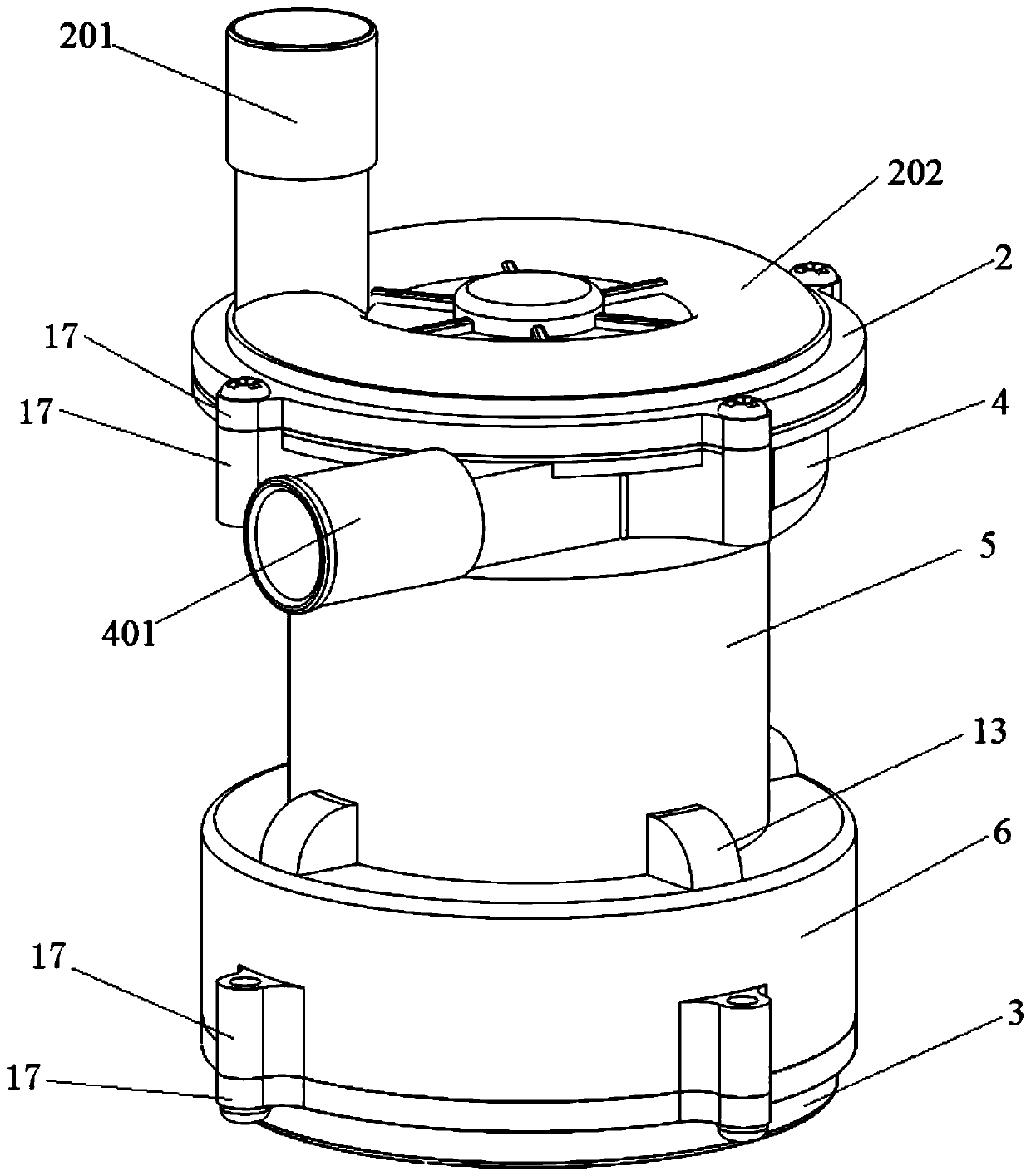

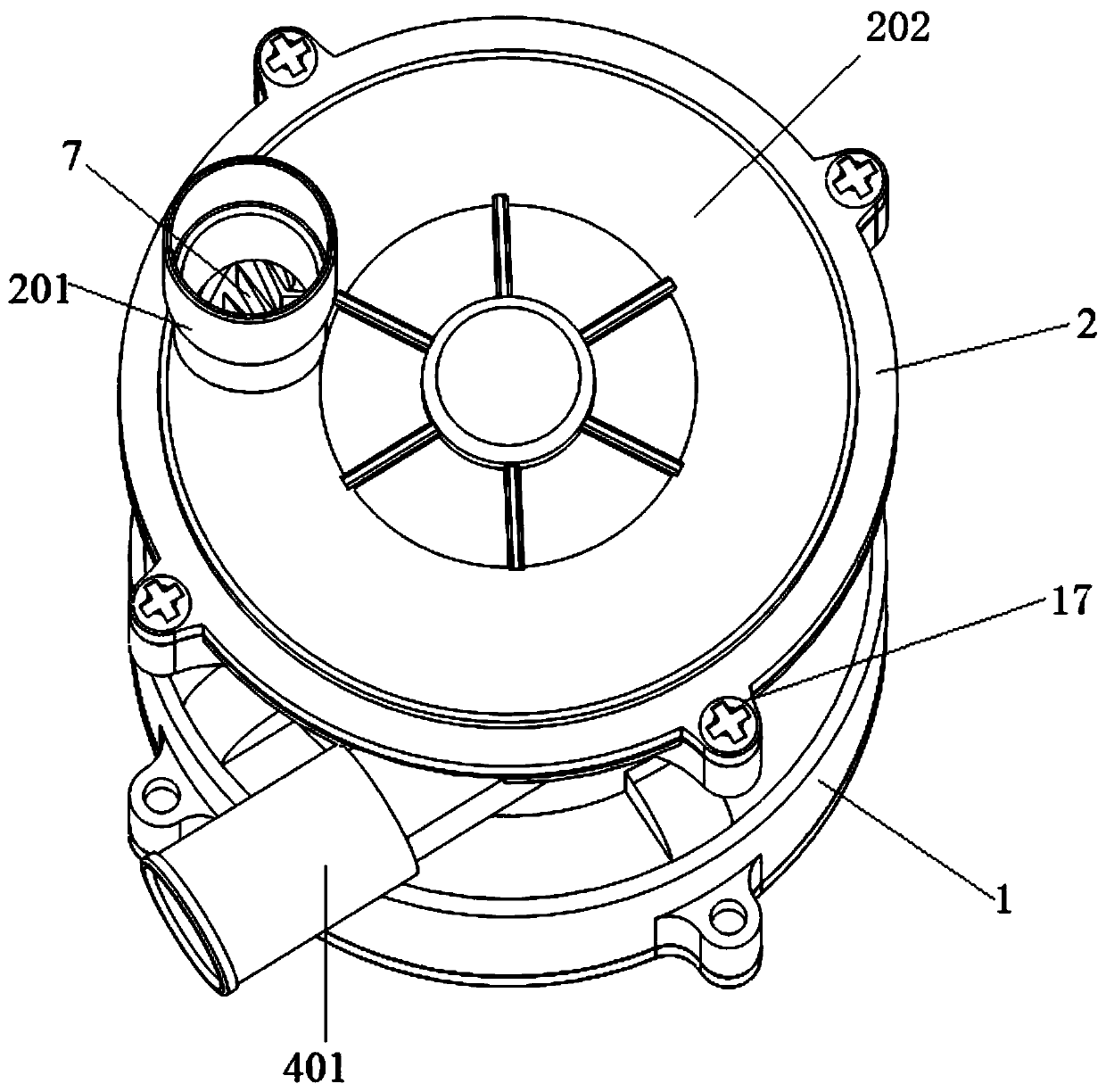

[0050] Such as Figure 1-Figure 15 As shown, the secondary air pump driven by a brushless motor of the present invention includes a pump housing 1, a front end cover 2 and a rear end cover 3, and the front end cover 2 and the rear end cover 3 are respectively fixed on the sides of the pump housing 1. The upper and lower ends make the pump casing 1 form a closed space, which is compact in structure and small in size, which is convenient for use by cars and easy to assemble.

[0051] The pump housing 1 is sequentially divided into an impeller chamber 4, a brushless motor bearing chamber 5, and a controller installation chamber 6 from top to bottom, and an isolation pad is arranged between the brushless motor bearing chamber 5 and the controller installation chamber 6 plate 18, modular partitioning, to facilitate the assembly of the internal parts of the pump housing 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com