Double-chain reversing oil pumping method and oil pumping unit

A technology of double chain and pumping unit, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., which can solve the problems of special chain link fatigue damage, increased risk of equipment fatigue damage, and additional alternating stress. and other problems, to achieve the effect of eliminating additional alternating stress, reducing equipment adjustment time, and reducing failure rate and maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] refer to Figure 1 to Figure 7 ,Such as Figure 1 to Figure 7 A kind of double-chain reversing oil pumping method shown, comprises the following steps:

[0040] Step S10, the motor 40 drives the reducer 30 to rotate through the belt, so that the driving output shaft 31 and the driven output shaft 33 rotate;

[0041] Step S11, the driving output shaft 31 and the driven output shaft 33 simultaneously drive the chain 83 and the reversing mechanism 90 to form continuous motion;

[0042] Step S12, the reversing mechanism 90 drives the reciprocating frame 85 to move up and down;

[0043] Step S13, the reciprocating frame 85 drives the traction belt 60 to move up and down;

[0044] Step S14, the traction belt 60 drives the wire suspension rope 70 to move up and down through the first belt roller 55 and the second belt roller 56;

[0045] In step S15, the front end of the steel wire suspension rope 70 is connected to the sucker rod to realize the up and down reciprocating m...

Embodiment 2

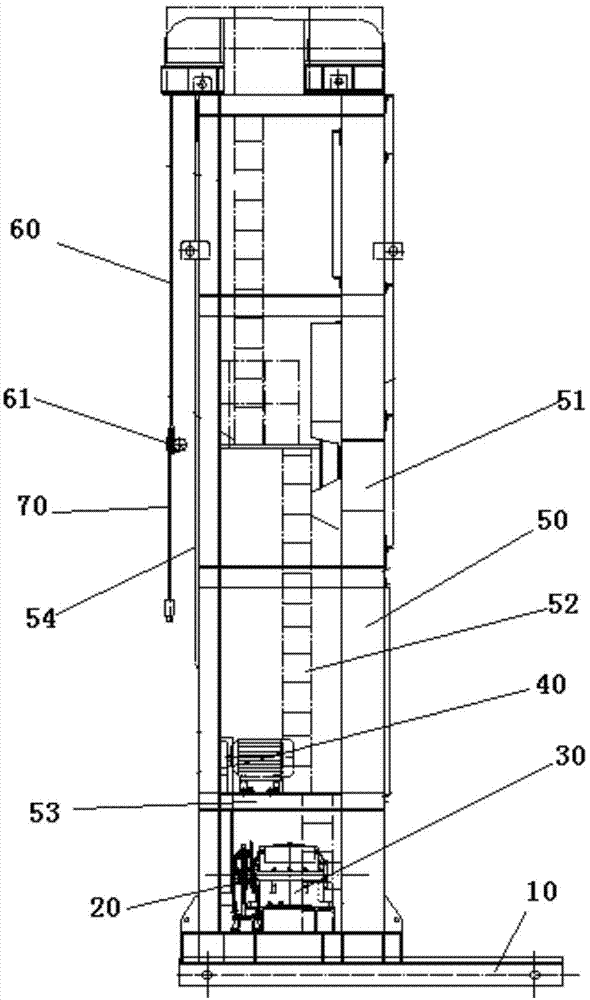

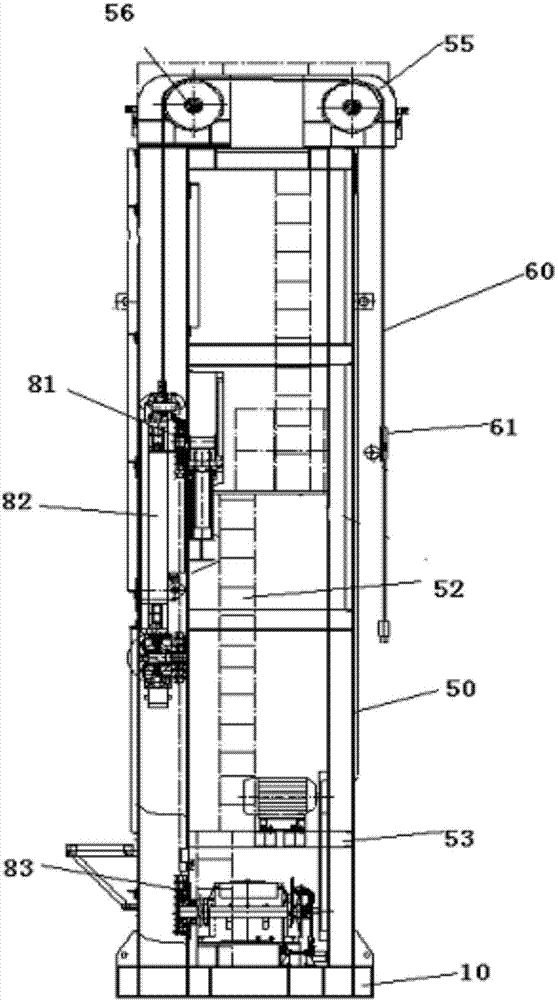

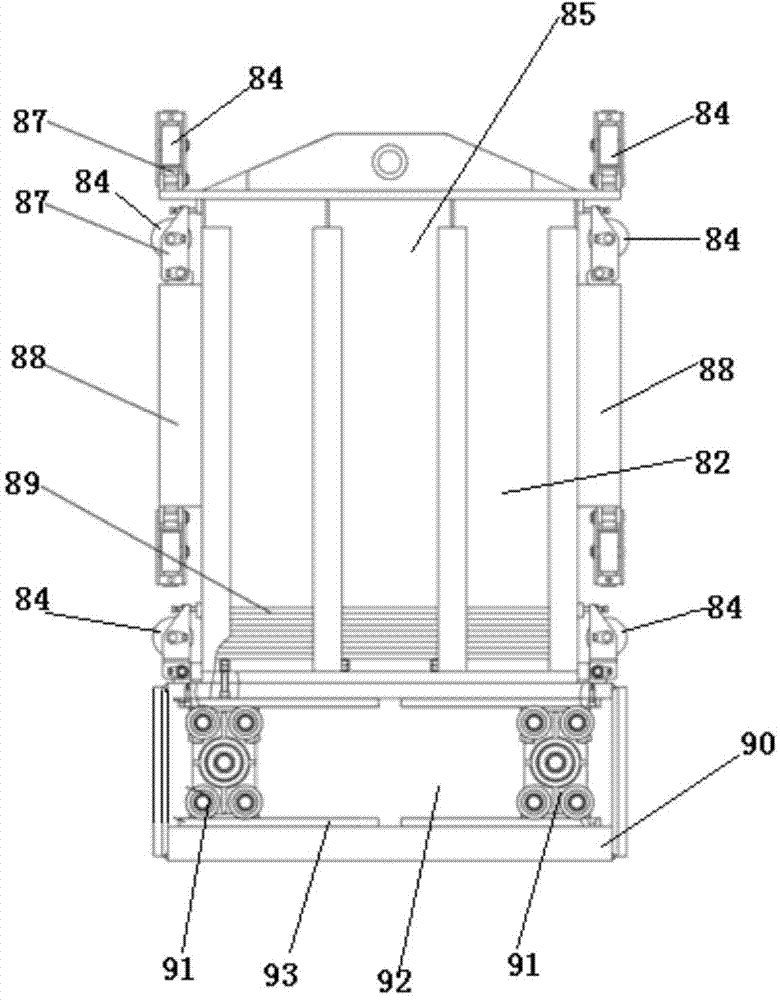

[0049] refer to Figure 1 to Figure 7 ,Such as figure 1 The shown double chain reversing pumping unit includes a base 10 and a tower 50 arranged on the base 10, wherein the top of the tower 50 is provided with a first belt roller 55 and a second belt roller parallel to each other 56, the first belt roller 55 and the second belt roller 56 balance and support the traction belt 60, so that the force on the tower 50 is balanced, and the tower 50 is provided with two sets of lower sprockets 81 and two sets of upper sprockets 86, The lower sprocket 81 and the upper sprocket 86 are provided with a chain 83, one side of the tower 50 is provided with a reciprocating frame 85, and the bottom of the reciprocating frame 85 is provided with a reversing mechanism 90, and the reversing mechanism 90 is provided with The reversing wheel group 91, the reversing wheel group 91 is provided with the chain link 914 that is connected with the chain 83, and the traction belt 60 is connected to the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com