Pure electric vehicle heat pump air conditioning system

A technology for pure electric vehicles and heat pump air conditioners, applied in vehicle components, air handling equipment, heating/cooling equipment, etc., to solve problems such as limited thermal energy, frost around heat exchangers, and inability to reach a comfortable temperature, saving space and cost, to achieve high temperature protection, the effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

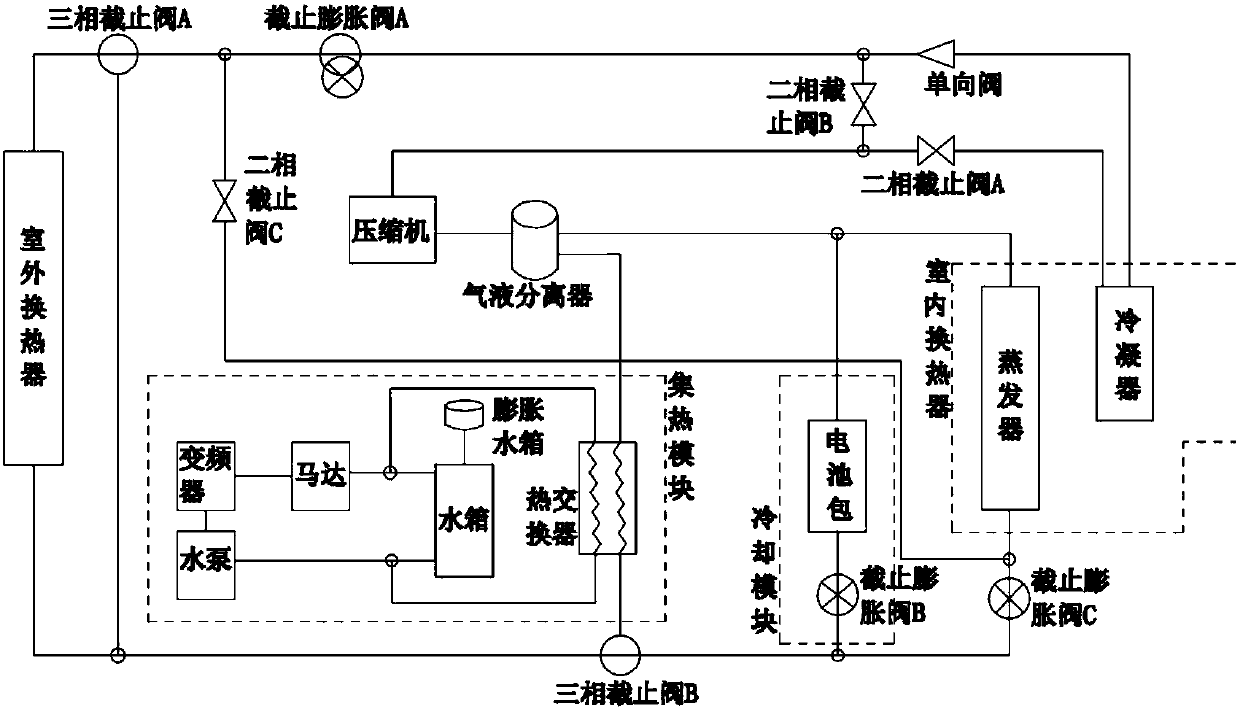

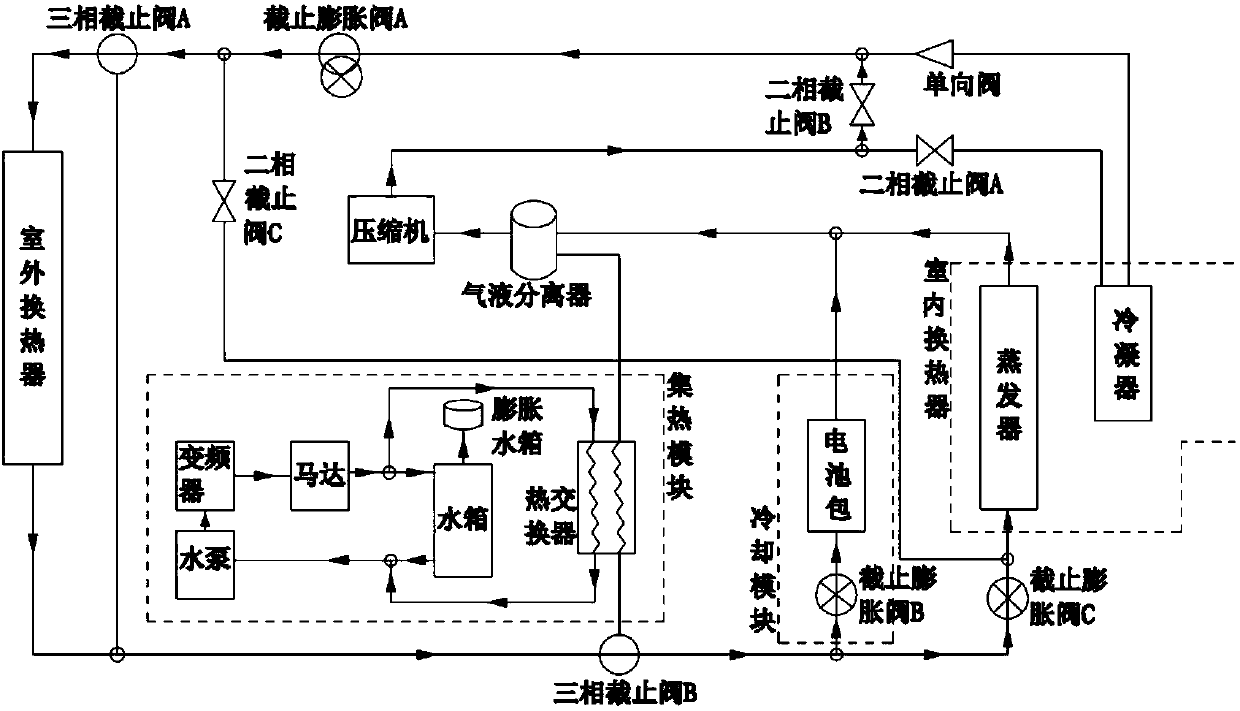

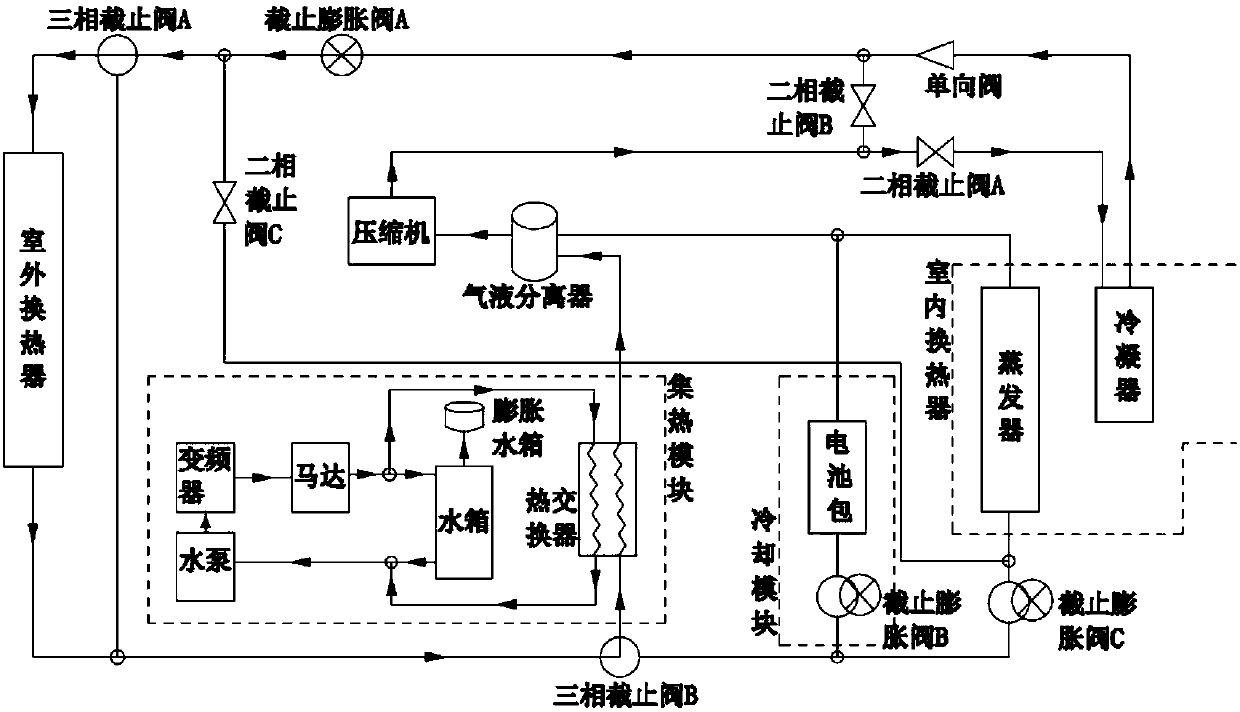

[0023] see Figure 1-Figure 7 As shown, the technical solution adopted in this specific embodiment is: it includes a compressor, a two-phase shut-off valve A, a two-phase shut-off valve B, a shut-off expansion valve A, a two-phase shut-off valve C, a three-phase shut-off valve A, an outdoor heat exchange device, three-phase cut-off valve B, cut-off expansion valve C, indoor heat exchanger, gas-liquid separator, cooling module and heat collection module; The cooling module includes a battery pack and a cut-off expansion valve B, and the heat collection module includes a water pump, a frequency converter, a motor, a water tank, an expansion tank, and a heat exchanger; the water pump, frequency converter, motor, and water tank are connected in series in sequence, and the expansion The water tank is connected to the water tank; the compressor, two-phase stop valve A, condenser, stop expansion valve A, outdoor heat exchanger, three-phase stop valve B, stop expansion valve C, evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com