Graded heating pulverizing system based on heat pipe technology and control method thereof

A technology of graded heating and pulverization system, which is applied in lighting and heating equipment, indirect heat exchangers, grain processing, etc., can solve the problem of low temperature of air-powder mixture at the explosion-proof safety outlet of coal mills, and avoid the arrangement of heat exchange devices , high heat transfer efficiency, and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

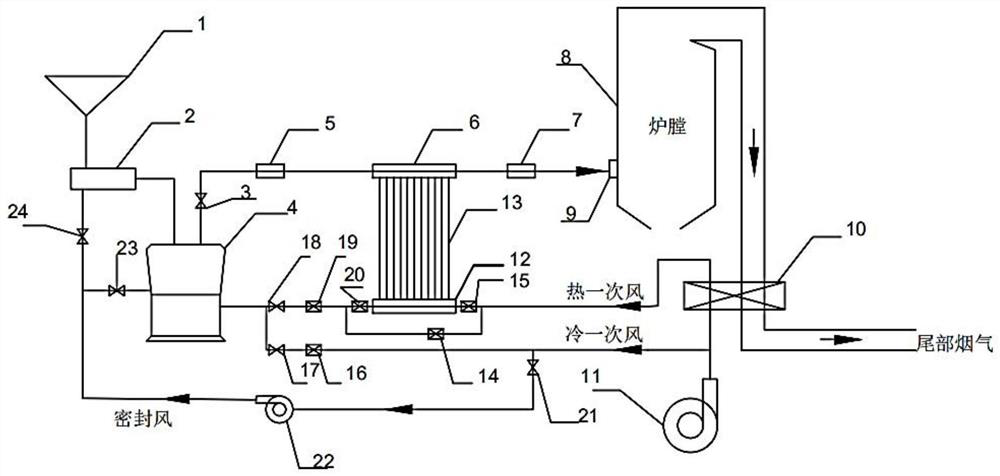

[0034] Such as figure 1 As shown, this embodiment provides a graded heating pulverization system based on heat pipe technology, which is divided into two stages of heating. The first stage of heating is hot primary air that passes through the coal mill to dry the raw coal and mixes and heats the pulverized coal during the process of conveying the pulverized coal. The secondary heating is to use the heat pipe technology to absorb the heat of the high-temperature hot primary air after the primary heating to further heat the pulverized coal transported. The system of this embodiment can basically eliminate or alleviate the problem of air powder energy mismatch before and after the coal pulverizer in the power plant boiler pulverizing system, and the problem that a certain amount of cold air needs to be mixed in order to reduce the temperature of the wind entering the coal pulverizer, and improve the efficiency of the boiler.

[0035] The graded heating pulverizing system includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com