Afterburner oil supply device

A technology of afterburner and fuel supply device, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problem of affecting the service life and safety of the engine, uneven distribution of atomized droplet diameter, and increasing the fuel cycle. The distribution range and other problems can be overcome to overcome the large inlet airflow velocity, reduce the length and improve the thrust-to-weight ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

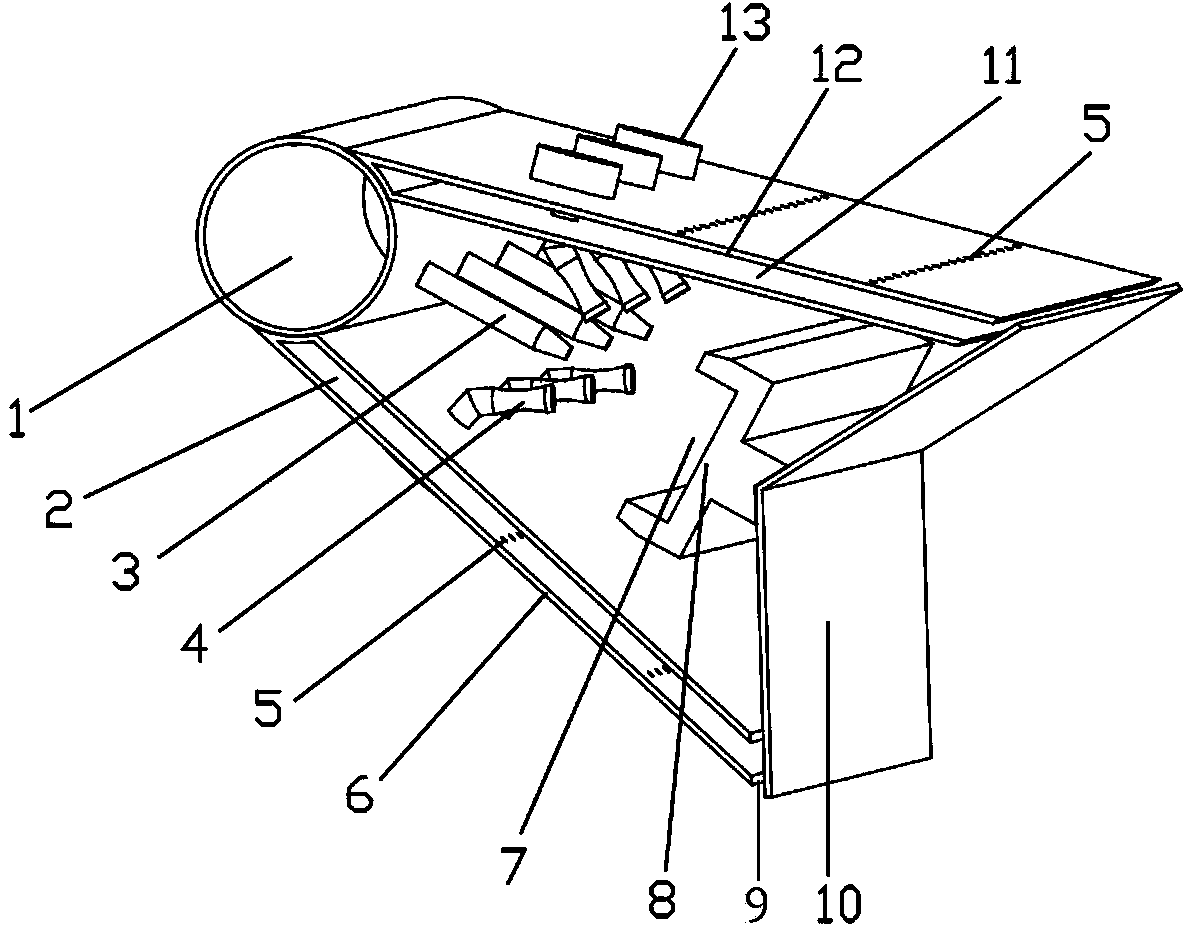

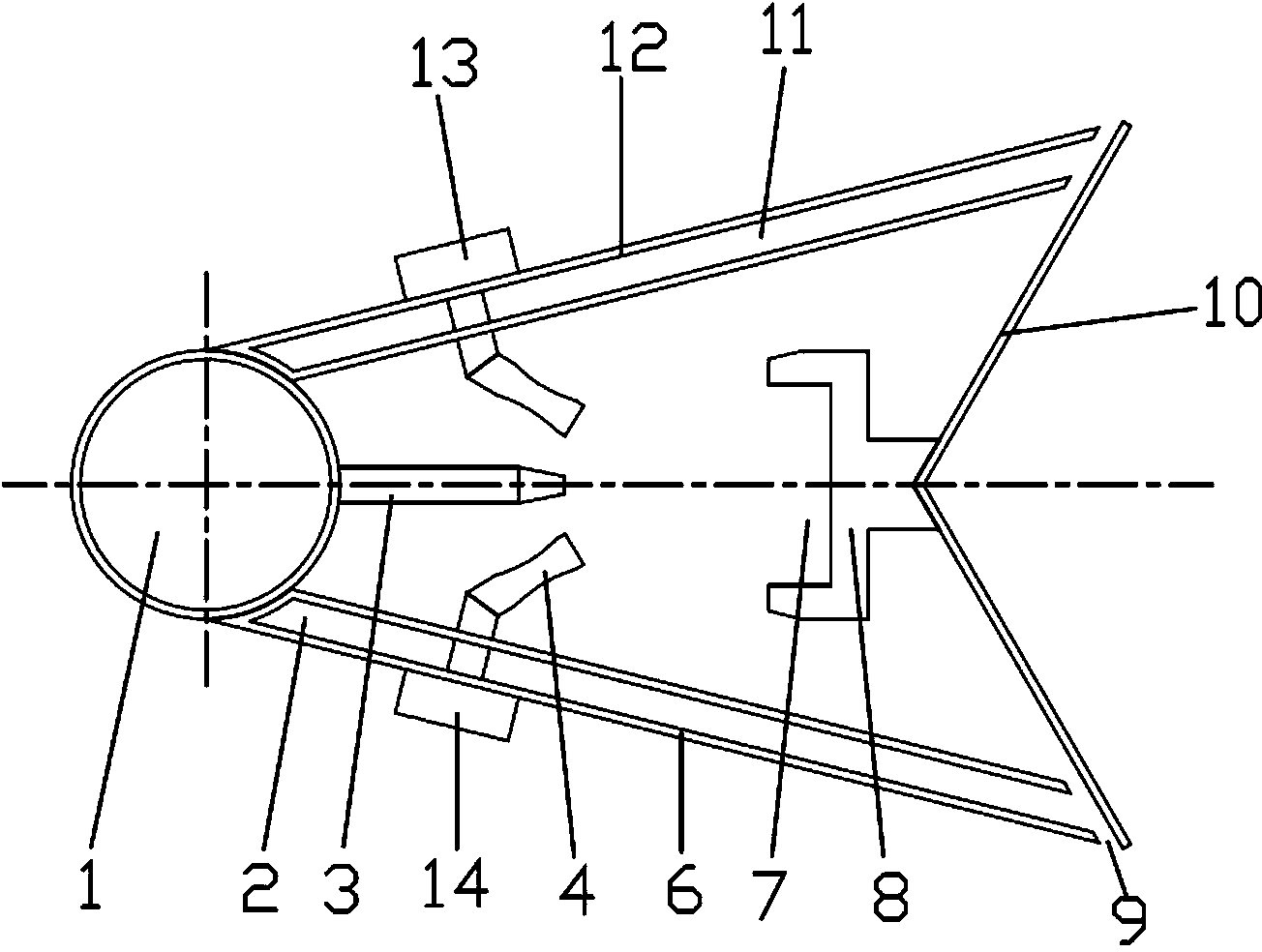

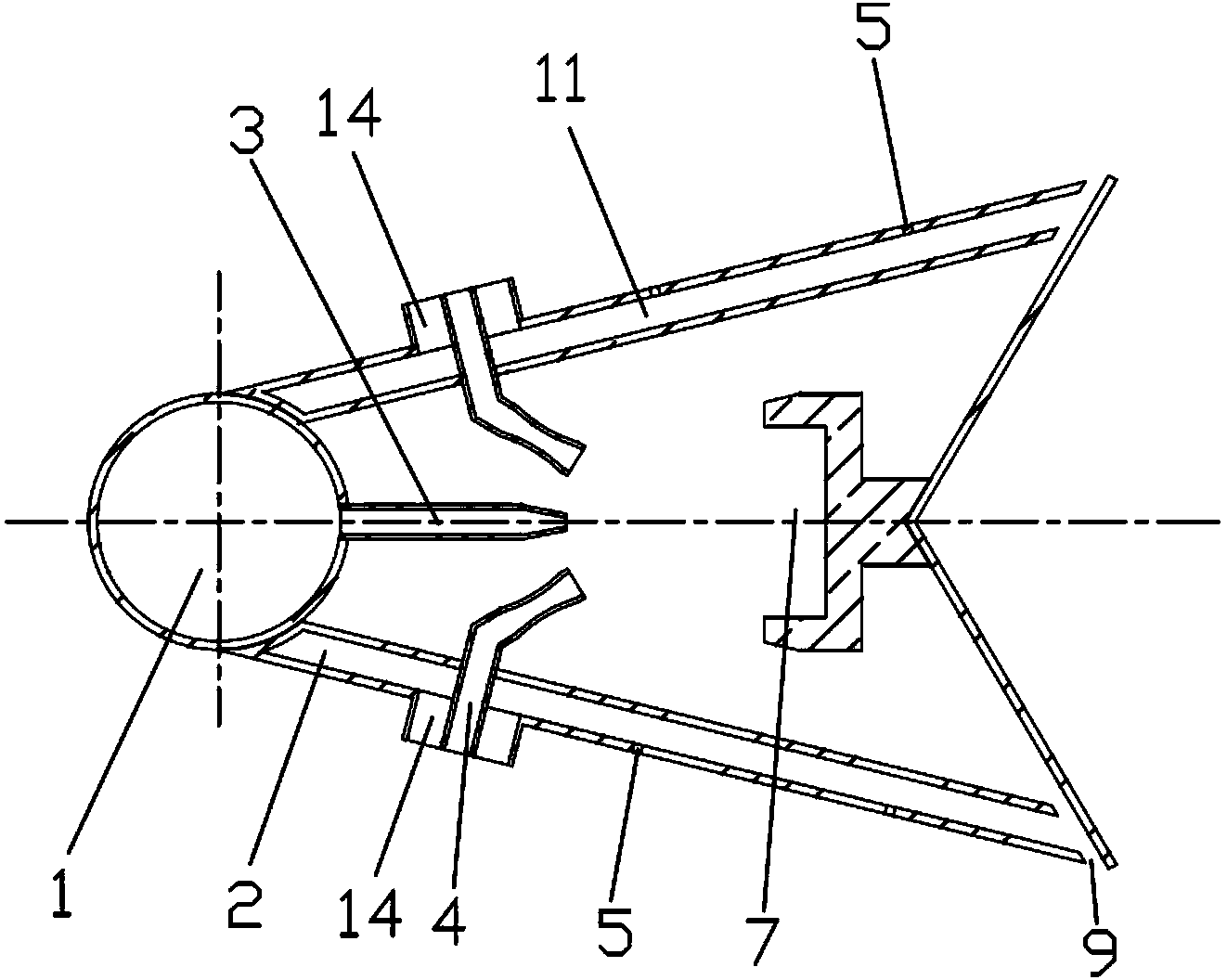

[0023] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, that is, the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0024] like Figure 1~4 As shown, the embodiment of the present invention is provided with a fuel supply pipe 1, an inner cooling chamber 2, a fuel nozzle 3, an air supply pipe 4, an inner wall surface 6, a resonant cavity 7, a resonant cavity body 8, a slot 9, a V-shaped baffle 10, Outer cooling cavity 11, outer wall surface 12, outer cooling cavity air inlet 13, inner cooling cavity air inlet 14.

[0025] The fuel supply pipe 1 is located at the head of the fuel supply device, and is in direct contact with the heat flow from the outlet of the low-pressure turbine of the aero-engine during operation. When the fuel flows in the fuel supply pipe 1, it can be preliminarily heated. The g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com