A method for producing sustainable composite materials designed for the production of elements for structural or non-structural use, and the material obtained

A composite material and structural technology, applied in the direction of building components, building materials, building structures, etc., can solve the problems of non-containment and retention, and achieve the effect of reducing deformation, improving performance, and high mechanical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

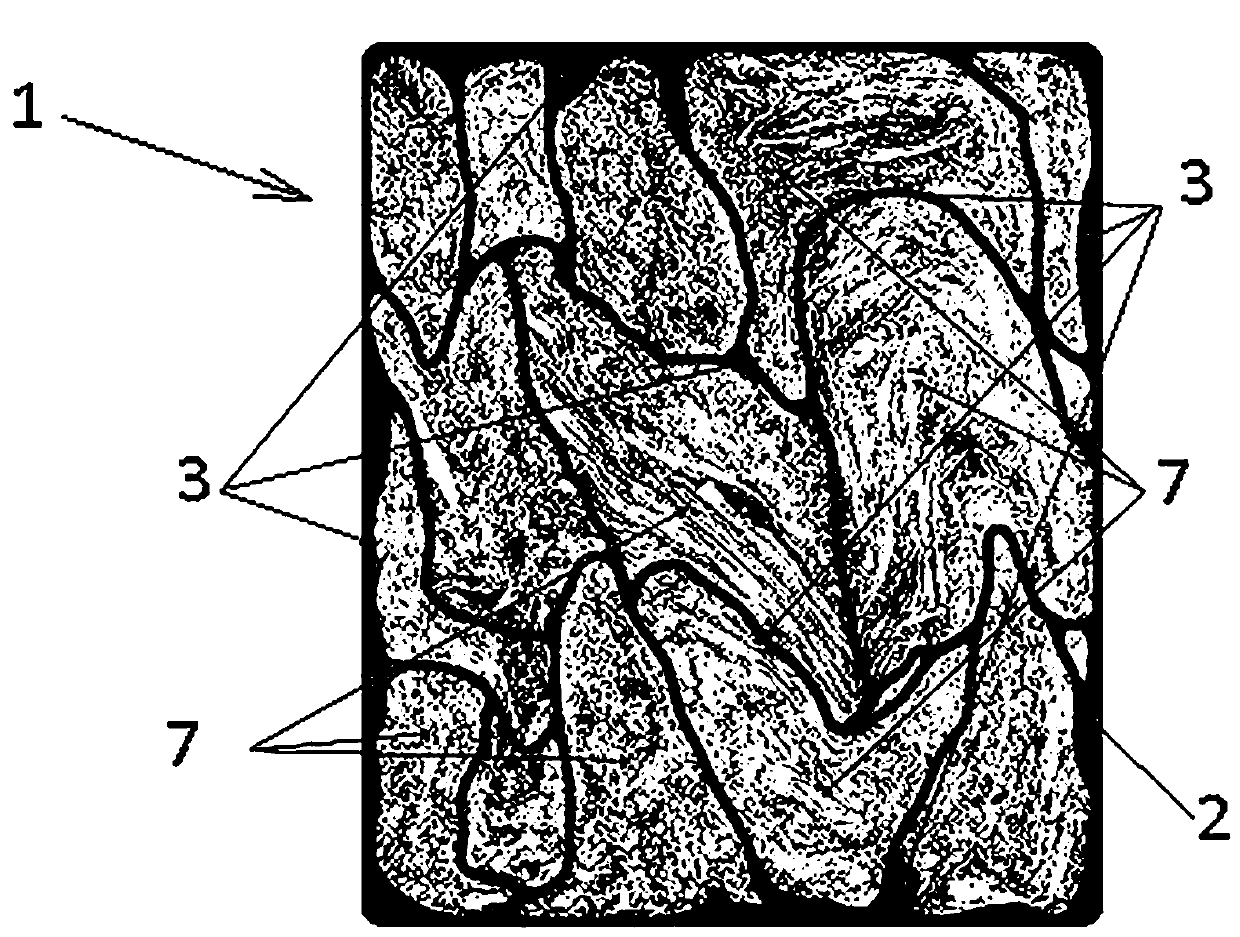

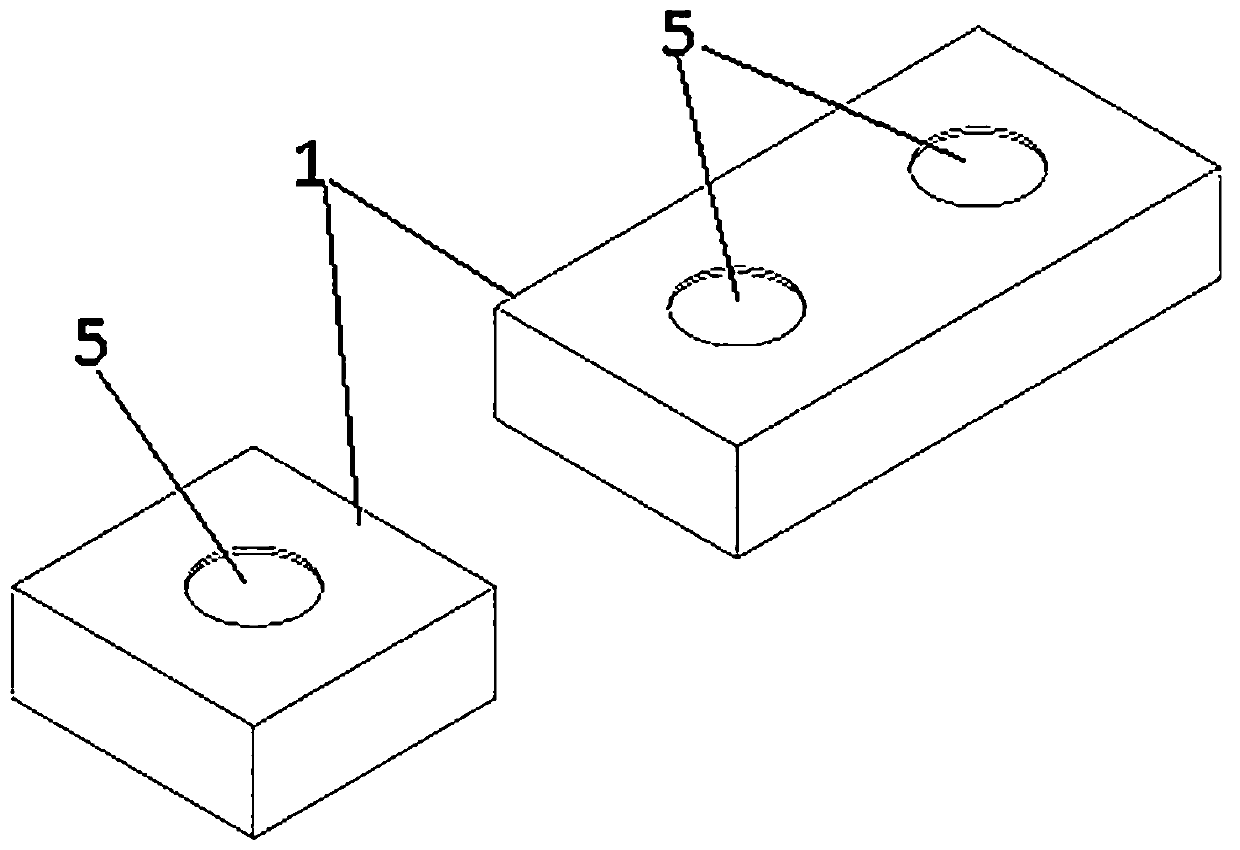

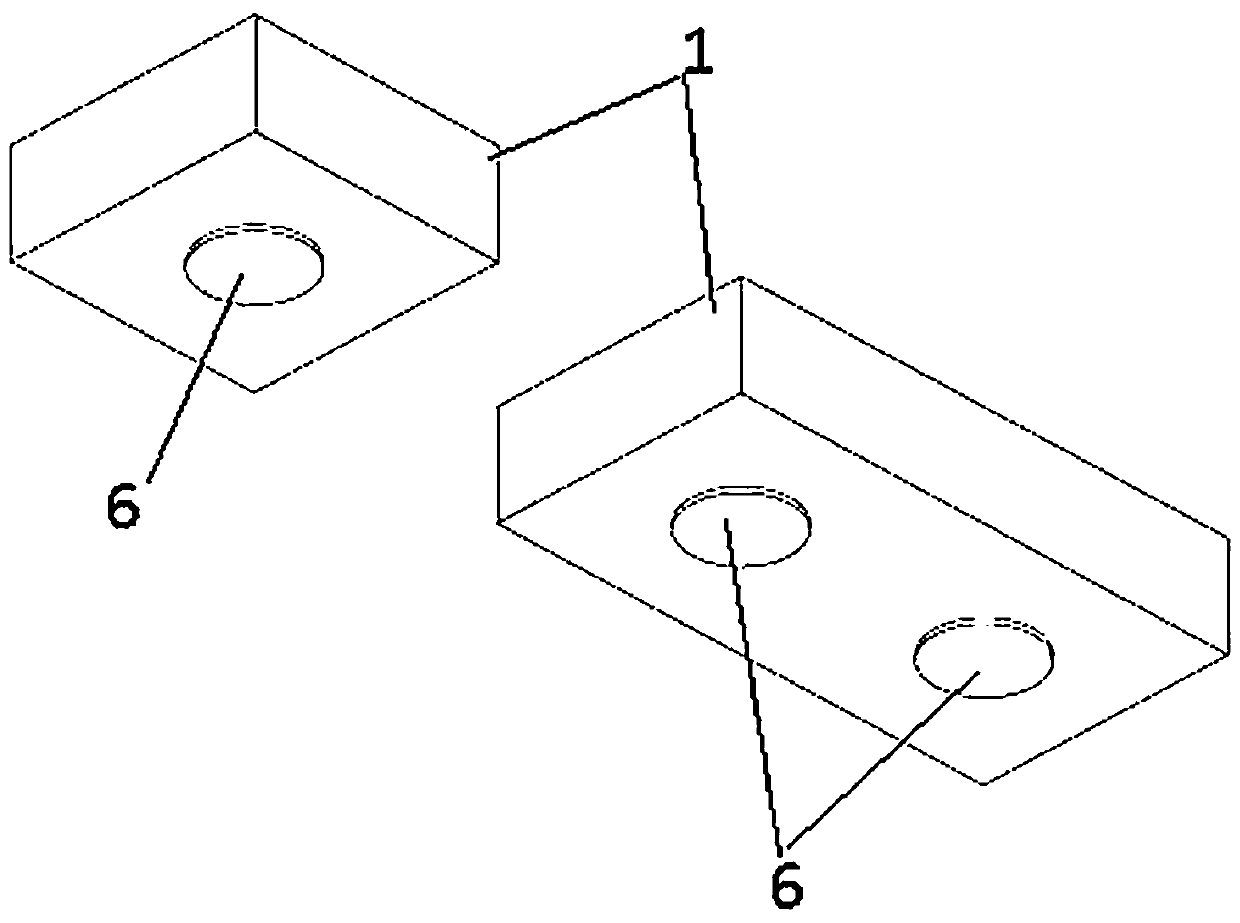

[0037] With reference to the accompanying drawings, the examples describe preferred embodiments of the method according to the invention for the production of prestressed elements (with reference to blocks) made of composite material for structural or non-structural use in the building sector product, said embodiments do not constitute a limitation of the invention, and the invention has been described according to preferred embodiments, but equivalent variants can be designed without departing from the scope of protection of the invention;

[0038]The idea of the method described in this embodiment consists in preparing a mold 8 whose shape and dimensions correspond to the final shape and dimensions of the desired block.

[0039] Preferably, it is made of materials permeable to high-frequency electromagnetic radiation (microwaves), including but not limited to aluminum, glass fiber, wood, and plastic.

[0040] The mold is formed by side walls 12, a bottom 13 and a piston 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com