Resin pulley

A pulley and resin technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of bearing function reduction, outer ring deformation, rotation accuracy reduction, etc., to prevent creep Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

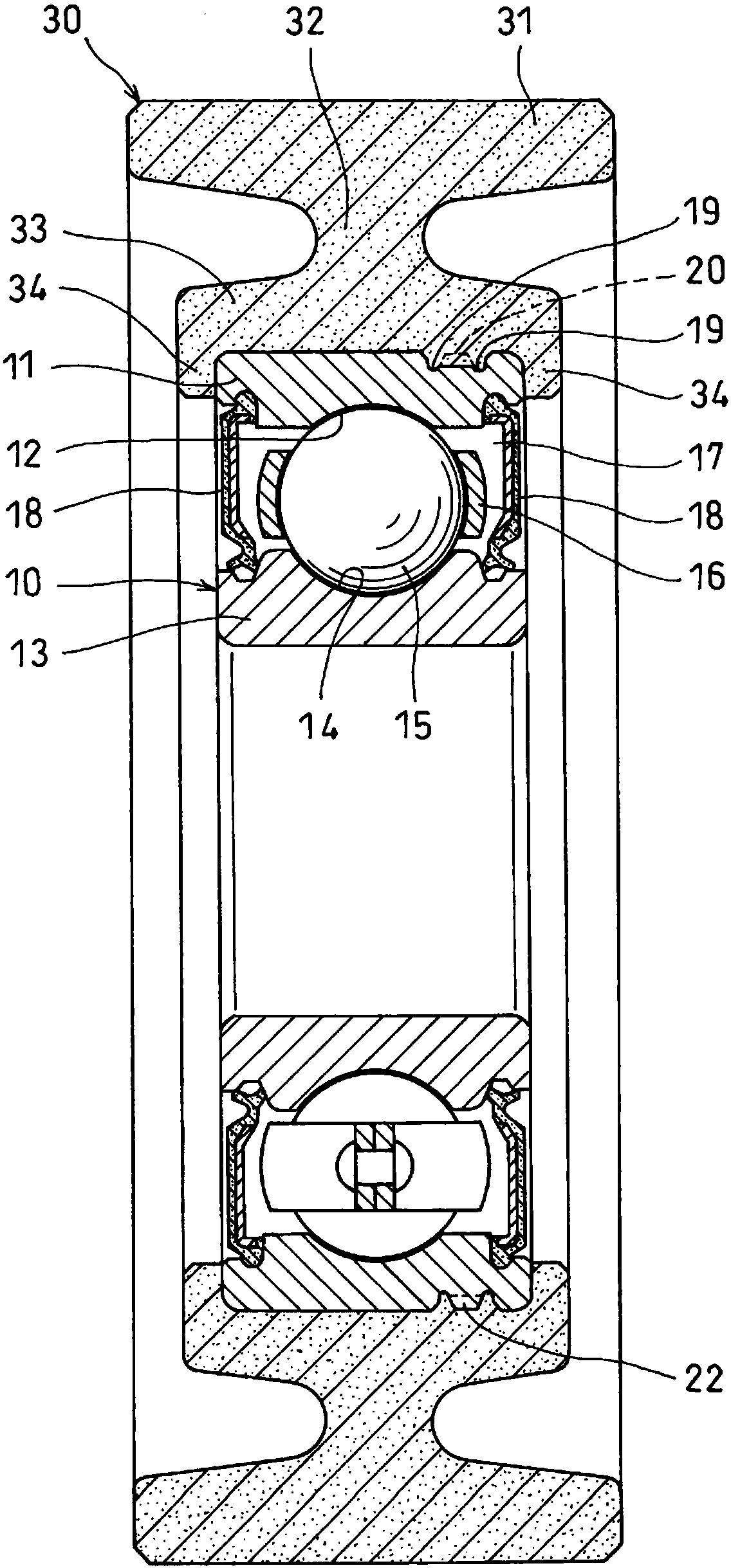

[0025] Embodiments of the present invention will be described below based on the drawings. Such as figure 1 As shown, the resin pulley is composed of a rolling bearing 10 and a pulley main body 30 provided on the outer periphery of the rolling bearing 10 .

[0026] Rolling bearing 10 is a deep groove ball bearing in which balls 15 are inserted between track grooves 12 formed on the inner diameter surface of outer ring 11 and track grooves 14 formed on the outer diameter surface of inner ring 13 , and balls 15 are held by cages 16 In this configuration, the openings at both ends of the bearing space 17 formed between the facing portions of the outer ring 11 and the inner ring 13 are closed by incorporating the seal member 18 .

[0027] In addition, the rolling bearing 10 is not limited to the deep groove ball bearing with a seal. For example, cylindrical roller bearings are also possible.

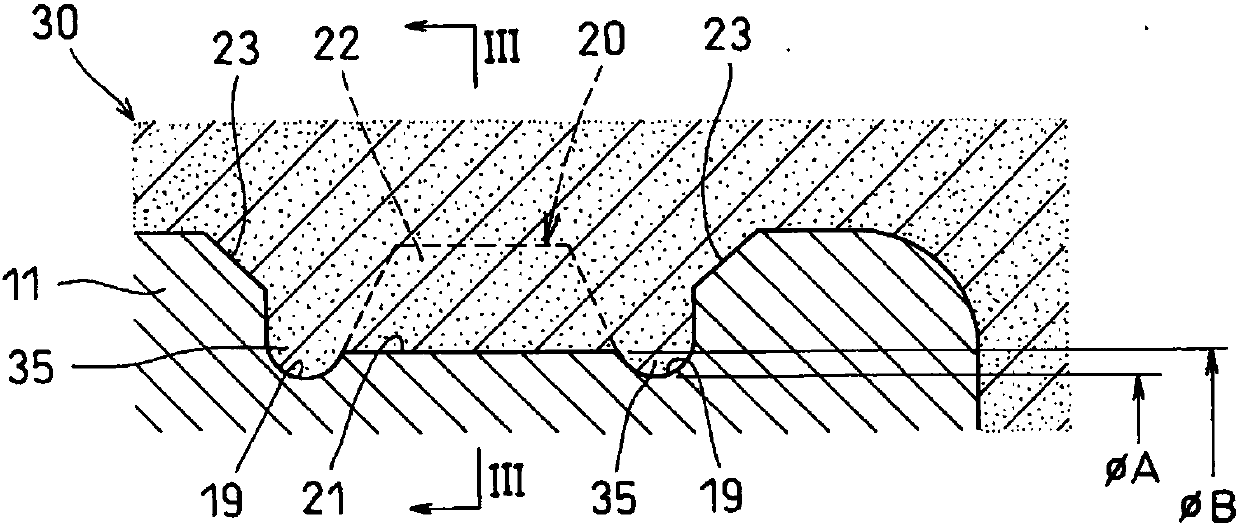

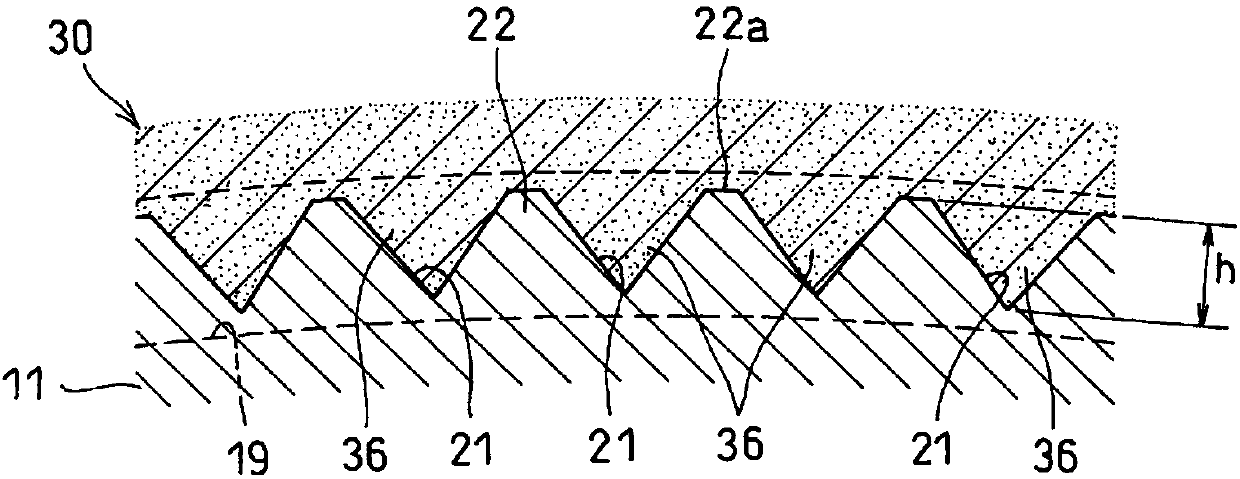

[0028] Such as Figure 2 ~ Figure 4 As shown, a pair of annular grooves 19 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com