Refractory castable conveying equipment capable of achieving efficient heat dissipation and deposition prevention

A technology for refractory castables and conveying equipment, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as solidification retardation and equipment failure to operate normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

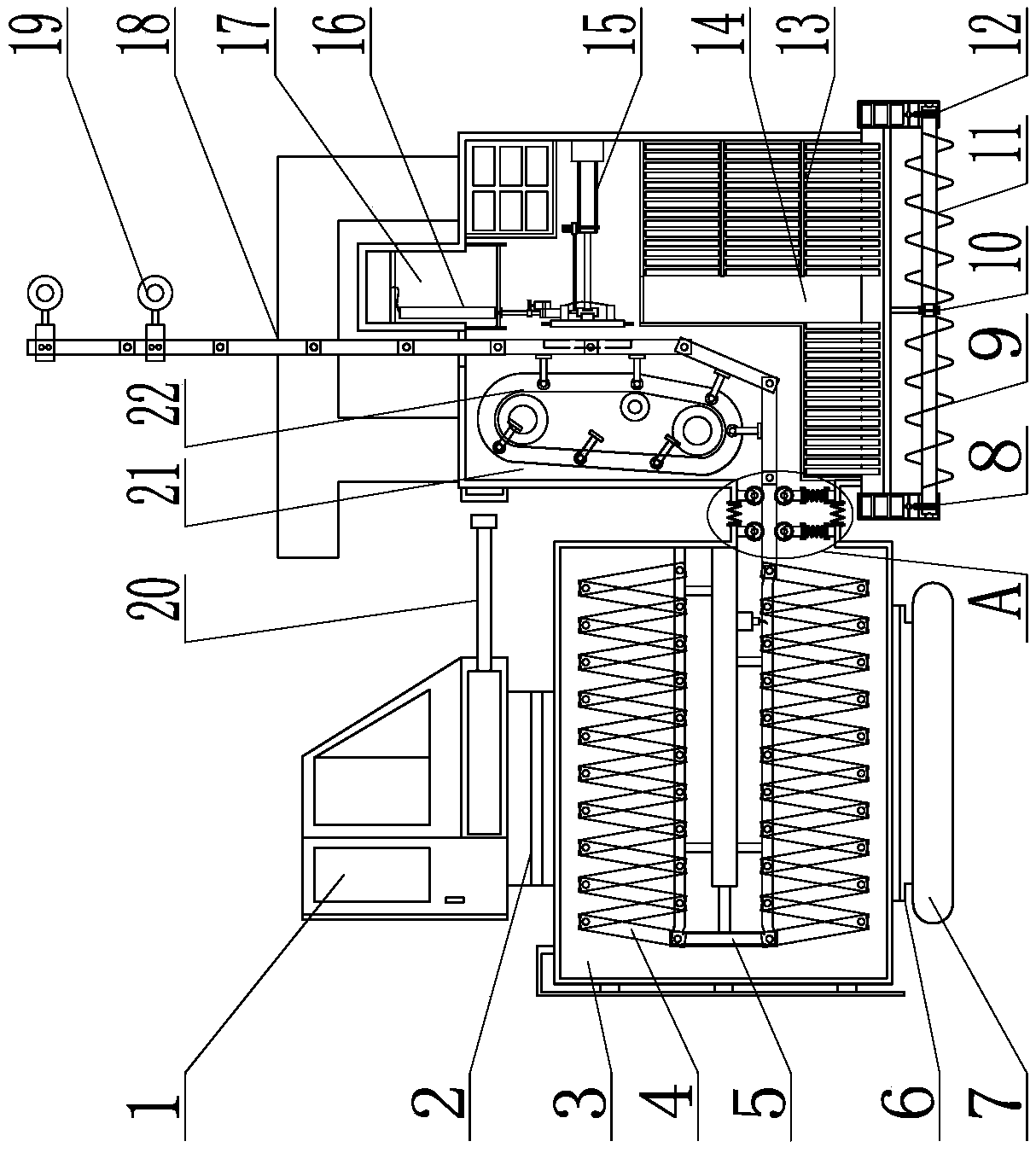

[0046] Such as Figure 8 As shown, a refractory castable conveying equipment capable of efficiently dissipating heat and preventing precipitation includes four parts: a mixing device, a feeding device, a conveying device and a feeding device. The four parts work together to complete the material delivery work.

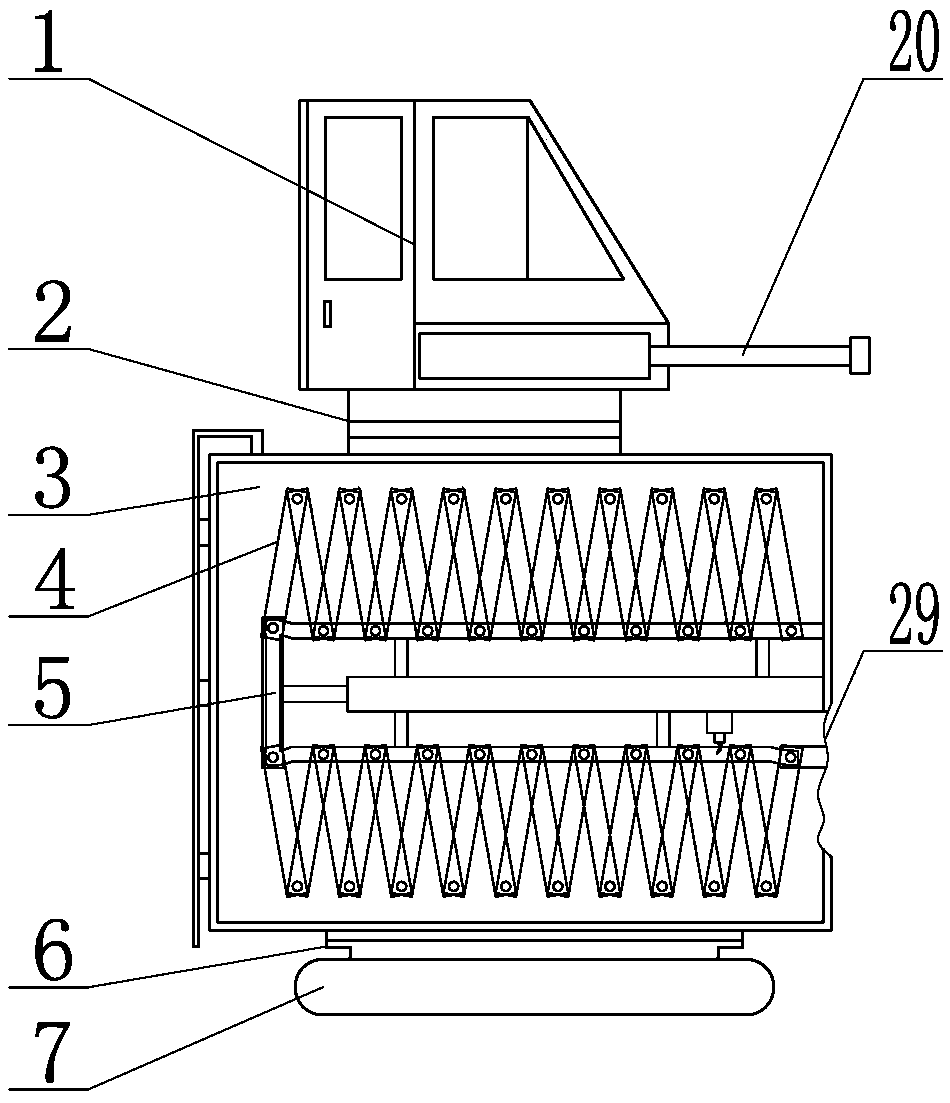

[0047] Such as Figure 9 As shown, the mixing device includes a mixing bracket and a mixing funnel. The upper opening of the mixing funnel is a premixing inlet, and the material enters the mixing equipment from the mixing inlet. The lower opening of the mixing funnel is a premixing inlet. The material outlet, after the material mixing is completed, enters the next working link. The mixing funnel is installed on the mixing bracket, and a mixing power device is installed in the mixing funnel. The mixing power device is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com