Lifting trolley used for transporting cuboid metal plates in neutralization box

A metal plate and cuboid-shaped technology, which is applied in the direction of lifting frames and lifting devices, can solve the problems of inconvenient handling and easy scattering of rectangular metal plates, and achieve the effects of easy automatic management, simple and efficient operation, and low handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Figure 1-Figure 7 As shown, the specific implementation is as follows:

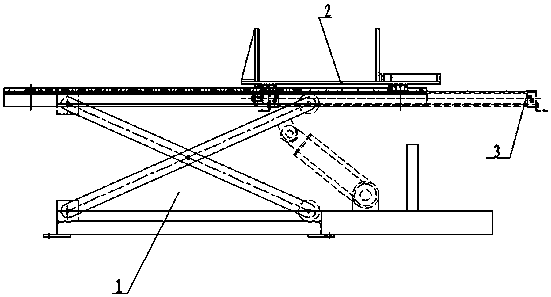

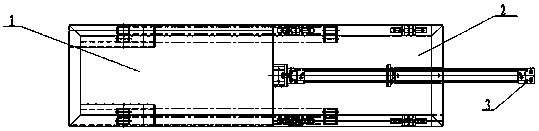

[0028] A lifting trolley for transporting rectangular parallelepiped metal sheets in a box, comprising a lifting device 1, a translation trolley 2 and a driving cylinder 3, the translation trolley 2 is slidably arranged on the top of the lifting device 1, and the protruding end of the driving cylinder 3 is fixed on the translation On the trolley 2, the other end of the driving cylinder 3 is fixed on the lifting device 1, and the reciprocating motion of the piston in the driving cylinder 3 drives the translation trolley 2 to reciprocate and slide horizontally on the top of the lifting device 1.

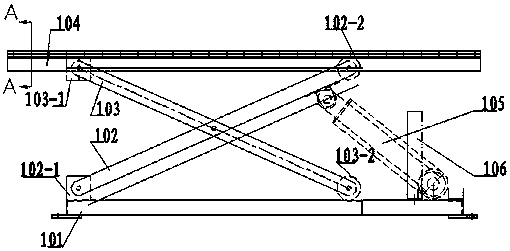

[0029] The lifting device includes a base 101, an upper support plate 104, and a pair of lifting mechanisms 107 symmetrically installed between the base 101 and the support plate 104, and the lifting mechanism 107 includes a first connecting rod 102 and a second connecting rod 103, the first connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com