Vitamin C wastewater electrolysis oxidation pretreatment method

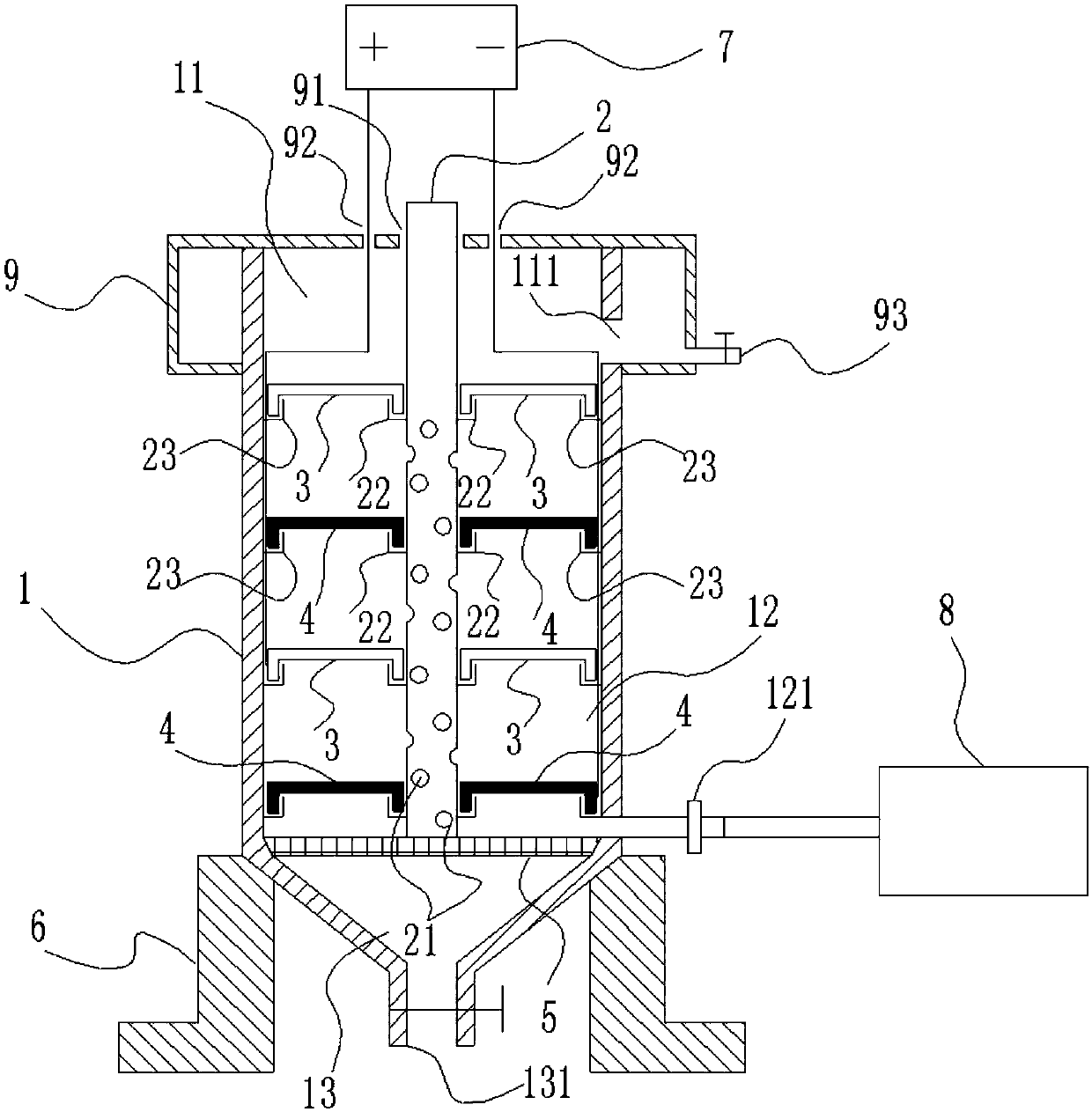

An electrolytic oxidation and vitamin technology, applied in biological water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problem of suspension parts affecting water intake and operation, low parallel plate treatment effect, small electrode area, etc. problems, to achieve the effect of easy cleaning and maintenance, reducing chromaticity and salt content, and expanding the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

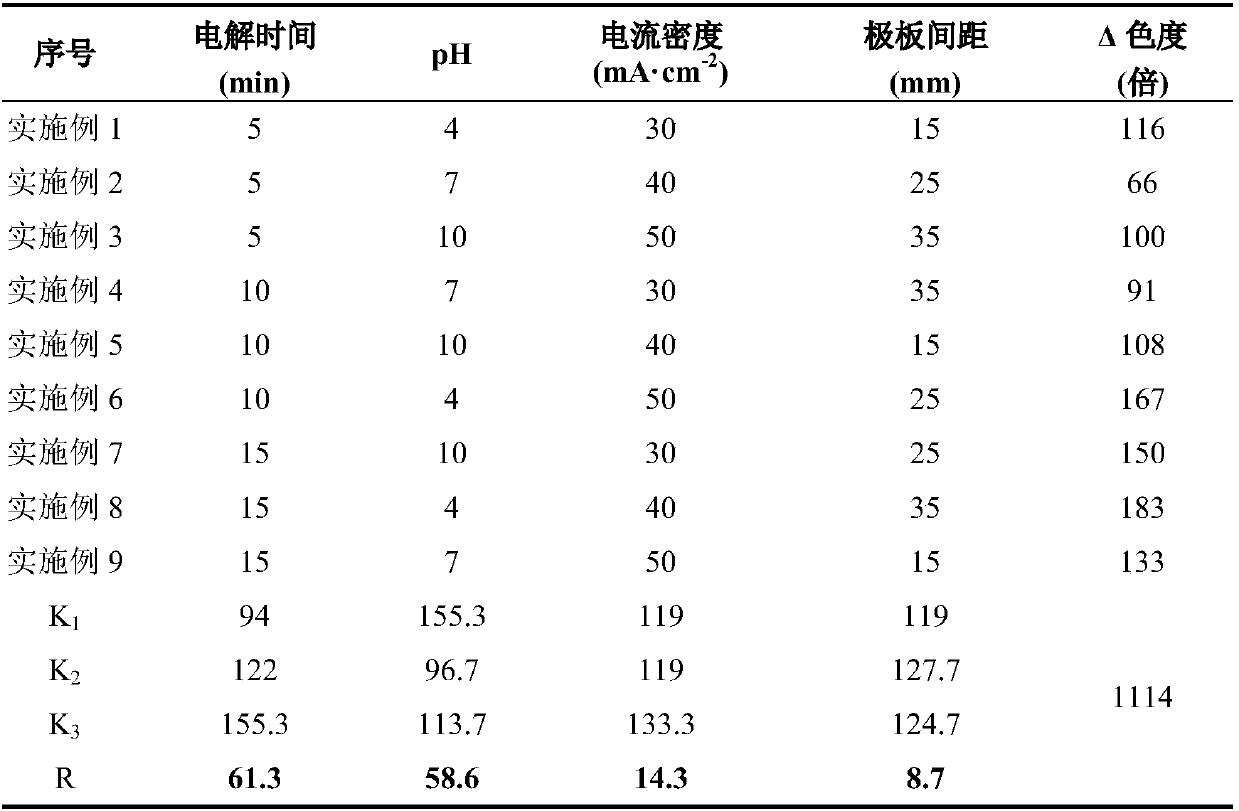

Examples

Embodiment 1

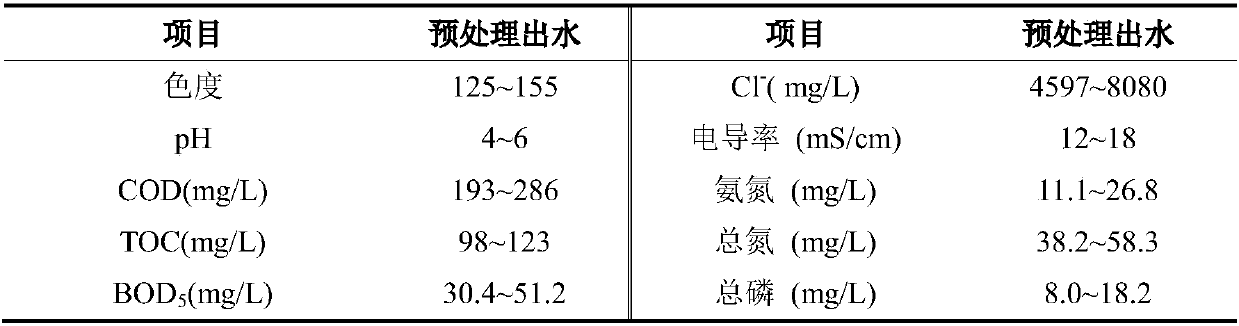

[0031] A method for electrolytic oxidation pretreatment of vitamin C wastewater, comprising the following steps:

[0032] S1: Lead the vitamin C wastewater after the secondary biochemical treatment into the water storage tank, use the bubbler to aerate the water for 15 minutes, and the aeration flow rate is 40m / s, and divide it into 3 times through the atomizer Add low-foam activators in batches, the total dosage of low-foam activators is 8g / L, and use low-foam activators to activate the surface layer of organic matter in vitamin C wastewater to obtain primary activated wastewater; among them, the fog output of the atomizer The tube is connected to the air outlet pipe of the bubbler. The atomizer atomizes the low-foam activator and sends it into the air outlet pipe through the mist outlet pipe. The atomized low-foam activator is carried by the gas blown into the air outlet pipe. into the vitamin C wastewater, the flow rate ratio of the atomized low-foam activator to gas is 1:8...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, the difference lies in the following parts:

[0045] S2: After the bubbling aeration is completed, skim off the upper foam of the primary activated wastewater, and adjust the pH value to 7, then use the water pump to pump the primary activated wastewater to flow through the pulse neutron activator, the water flow rate is 1m / s, The pulse frequency of the pulsed neutron activator is 10KHZ, the distance between the neutron source and the water surface is 0.5m, and the neutron fluence rate is 1×10 13 n.cm -2 .s -1 , using neutron transfer energy to deeply activate the organic matter in the first-level activated wastewater to obtain the second-level activated wastewater;

[0046] S3: The secondary activated wastewater is directly introduced into the electrolytic oxidation reactor for electrolytic oxidation reaction, and three-dimensional electrode particles are added. The volume ratio of the three-dimensional electrode...

Embodiment 3

[0048] This embodiment is basically the same as Embodiment 1, the difference lies in the following parts:

[0049] S2: After the bubbling aeration is completed, skim off the upper foam of the first-level activated wastewater, and adjust the pH value to 10, and then use the water pump to pump the first-level activated wastewater to flow through the pulse neutron activator at a flow rate of 1m / s. The pulse frequency of the pulsed neutron activator is 10KHZ, the distance between the neutron source and the water surface is 0.5m, and the neutron fluence rate is 1×10 13 n.cm -2 .s -1 , using neutron transfer energy to deeply activate the organic matter in the first-level activated wastewater to obtain the second-level activated wastewater;

[0050] S3: The secondary activated wastewater is directly introduced into the electrolytic oxidation reactor for electrolytic oxidation reaction, and three-dimensional electrode particles are added. The volume ratio of the three-dimensional el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com