Scraped automobile oil collection device

A collection device and technology for scrapped cars, applied in the direction of filtration and separation, only multi-stage series refining process treatment, filtration circuit, etc., can solve the problems of low recovery efficiency, cumbersome treatment process, and large power consumption, so as to improve recovery, Ease of use and high recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

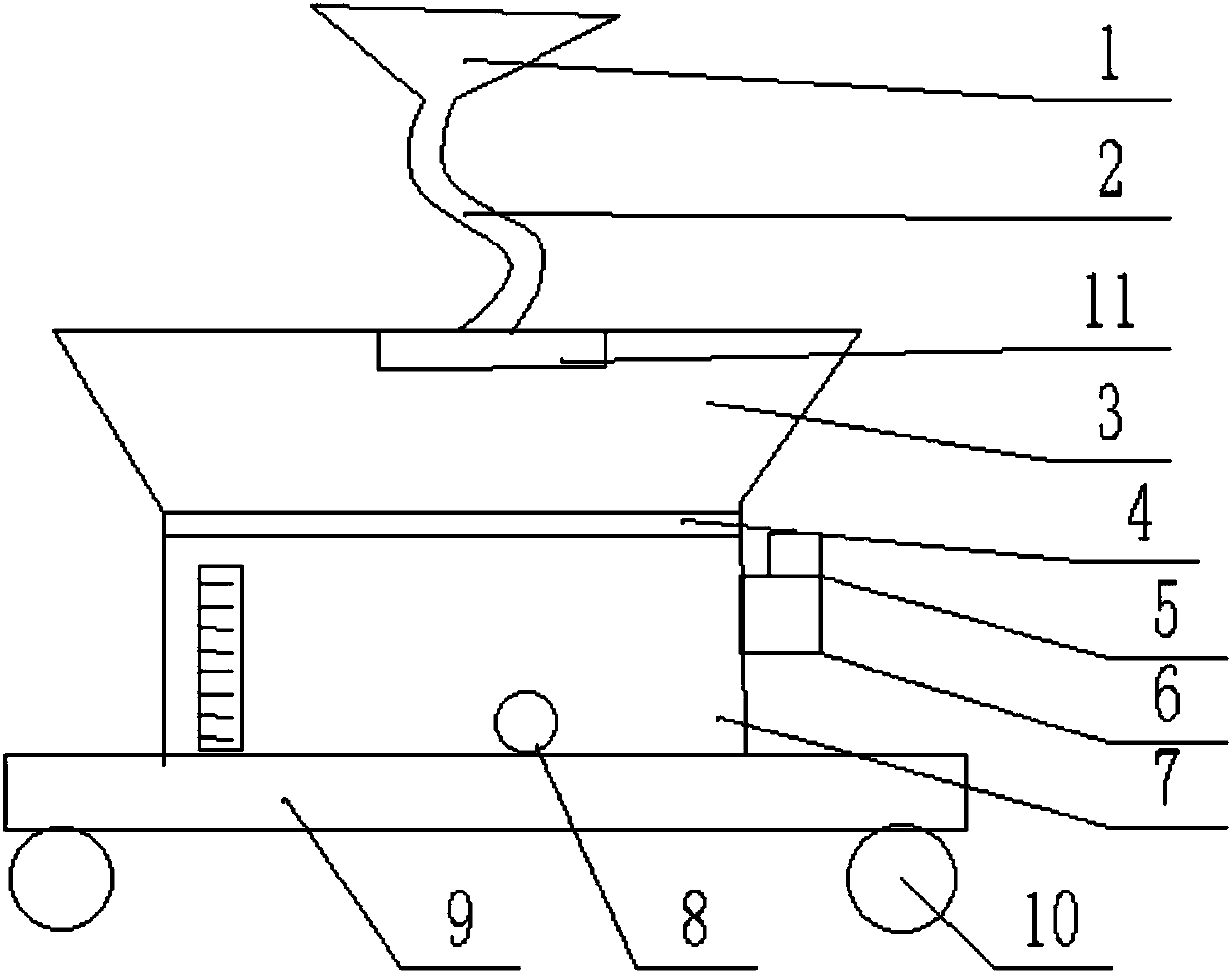

[0017] Such as figure 1 As shown, the present invention provides a kind of scrapped automobile oil liquid collecting device, comprising:

[0018] Sliding plate 9, the bottom of which is provided with rollers 10;

[0019] The waste oil tank is composed of an upper part 3 and a lower part 7. The upper part is a quadrangular platform structure with a large upper part and a smaller lower part. The lower part is a square structure. Both the upper part and the lower part 7 are connected hollow structures. The lower end of the lower part has A circular oil outlet 8, the top surface of the upper part has an oil inlet, and the inner side wall of the upper part is provided with a nano-coating.

[0020] The pumping mechanism is composed of a power chamber 6 and a pump 5, the power chamber communicates with the bottom of the waste oil tank, the pump communicates with the power chamber, and anhydrous calcium chloride is housed in the power chamber;

[0021] connecting pipe 2, which is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com