Robot RV-C type speed reducer

An RV-C, reducer technology, applied in mechanical equipment, transmission parts, gear transmissions, etc., can solve the problems of reduced transmission efficiency, large wheel-pin contact stress, easy wear, etc., to ensure normal work, good Dynamic performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

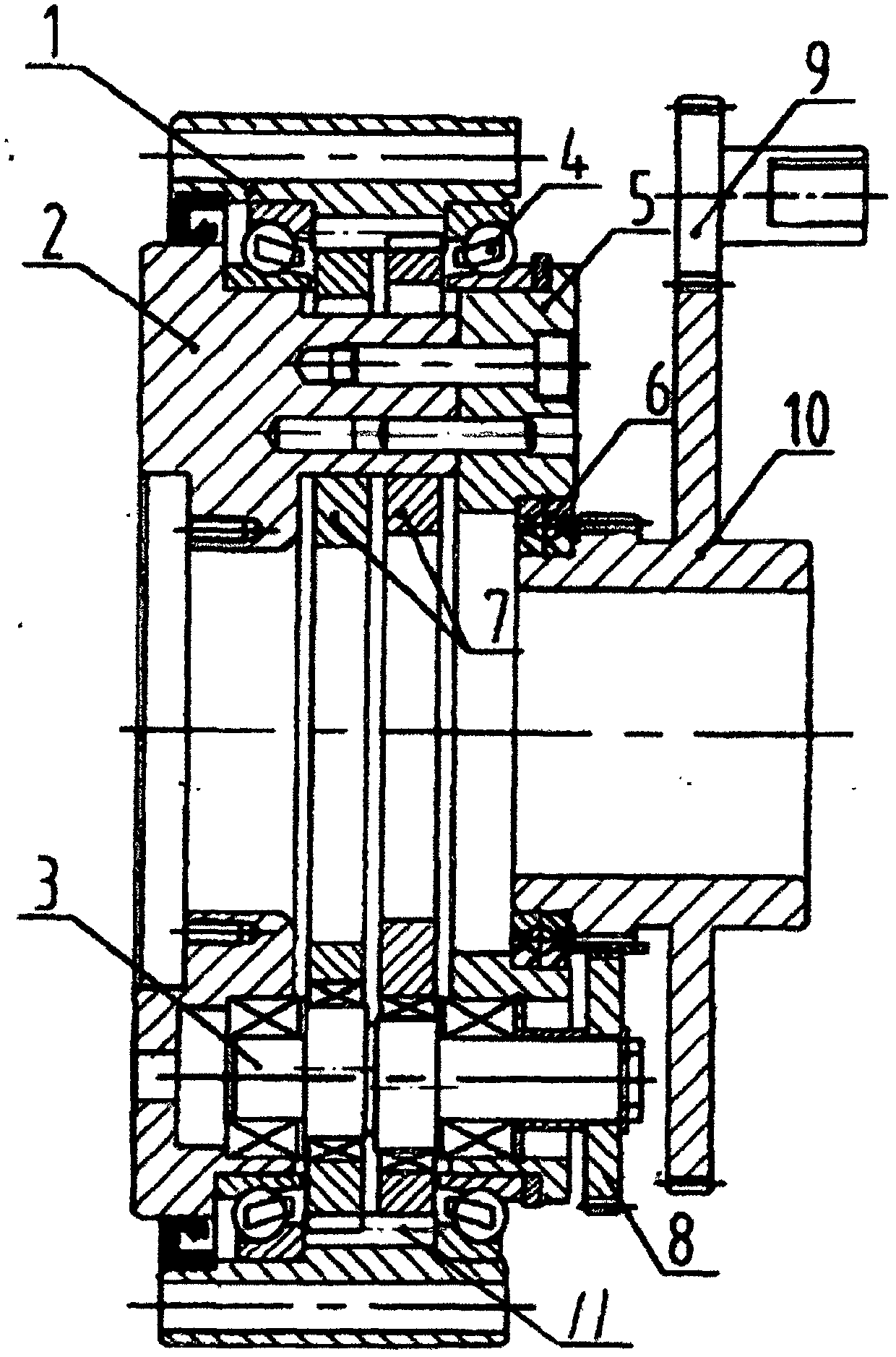

[0083] A robot RV-C type reducer, including input, planet, cycloid and output four parts, in which:

[0084] Described input part comprises the drive wheel 9 that is located on the servomotor and double gear 10, and double gear 10 comprises sun gear and the driven wheel that meshes with driving wheel 9, and the inner hole of double gear 10 is provided with line pipe;

[0085] The planetary components include the sun gear on the planetary gear 8 and the dual gear 10;

[0086] The cycloid part includes three evenly distributed eccentric shafts 3, two cycloidal wheels 7, pin gear housing 1 and pins 11, pin pins 11 are arranged in half-buried holes evenly distributed on the pin gear housing 1, and the pins The pin 11 meshes with the cycloidal wheel 7, and the extension end of the eccentric shaft 3 is connected to the planetary wheel 8;

[0087] The output part includes left and right rigid discs 2 and 5, and the left and right rigid discs 2 and 5 are respectively supported in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com