Particulate matter sampler with changeable filter membrane

A technology of automatic membrane change and particulate matter, which is applied in the direction of sampling devices, etc., can solve the problems of bulky small flow particle sampler, increase the work intensity of operators, and increase the labor intensity of operators, so as to meet the long-time sampling requirements and reduce labor intensity , The effect of high film changing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

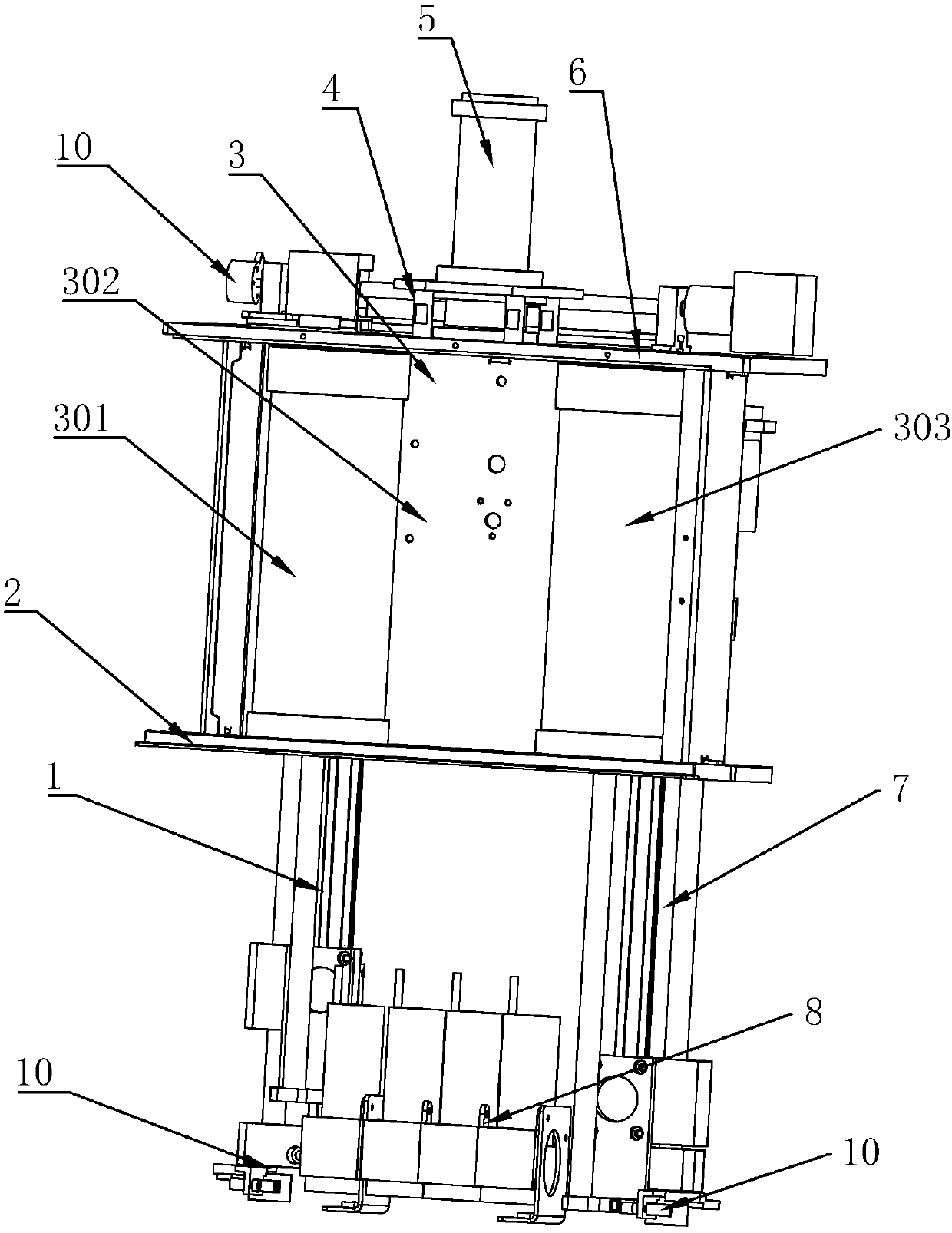

[0035] like Figure 1-2 As shown, an automatic membrane-changing particle sampler of the present invention includes a housing. In order to cope with various complex working conditions such as rain, snow, sand, lightning, and low temperature, the housing is a louver structure, which can make the particle sampler It can effectively ventilate and dissipate heat, and can prevent wind and snow. There is a dust-proof sponge on the inside of the louvers, which can effectively prevent sand and dust in the air from entering, so that the sampling data of the particle sampler is highly accurate, and the overall particle sampler can run stably.

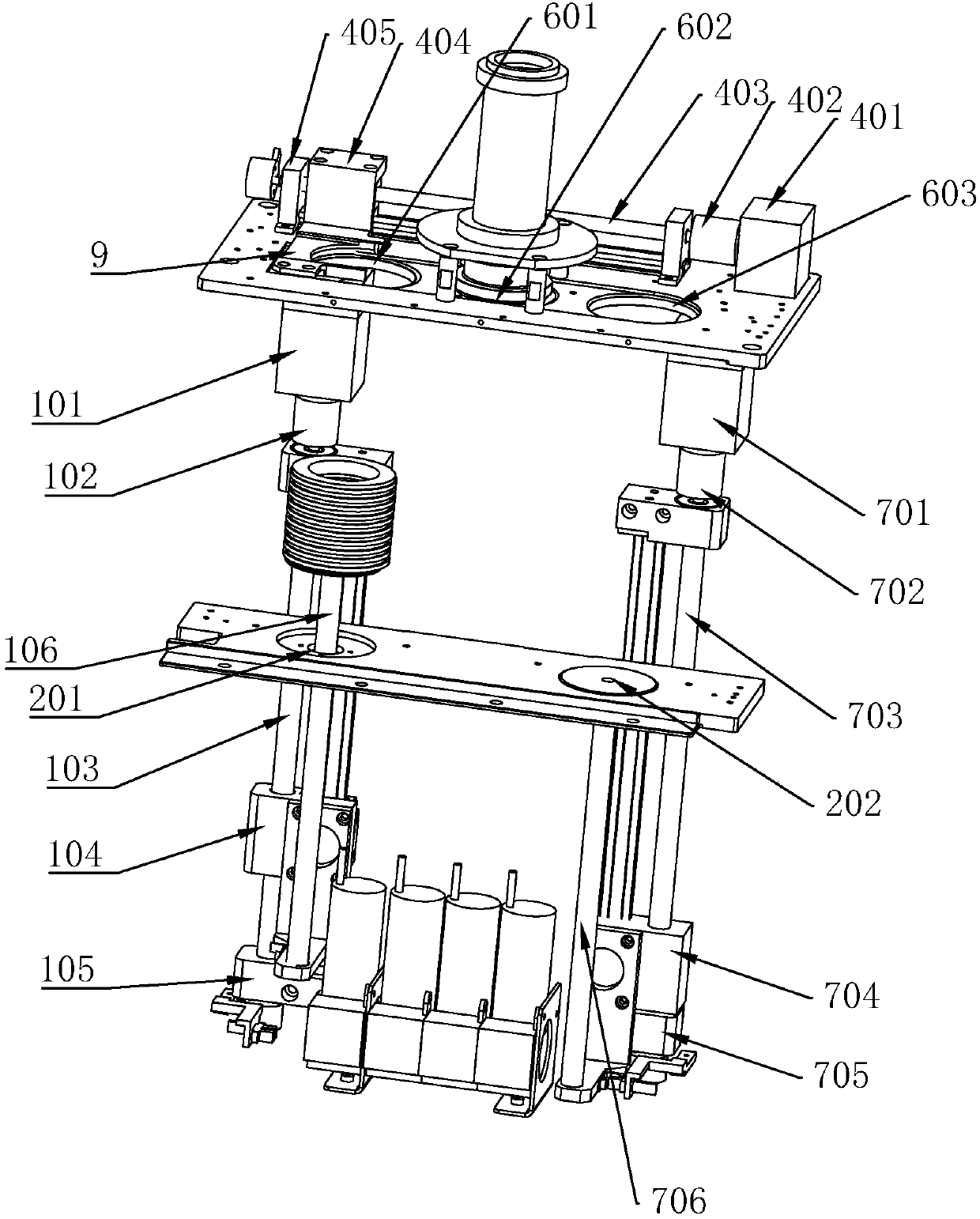

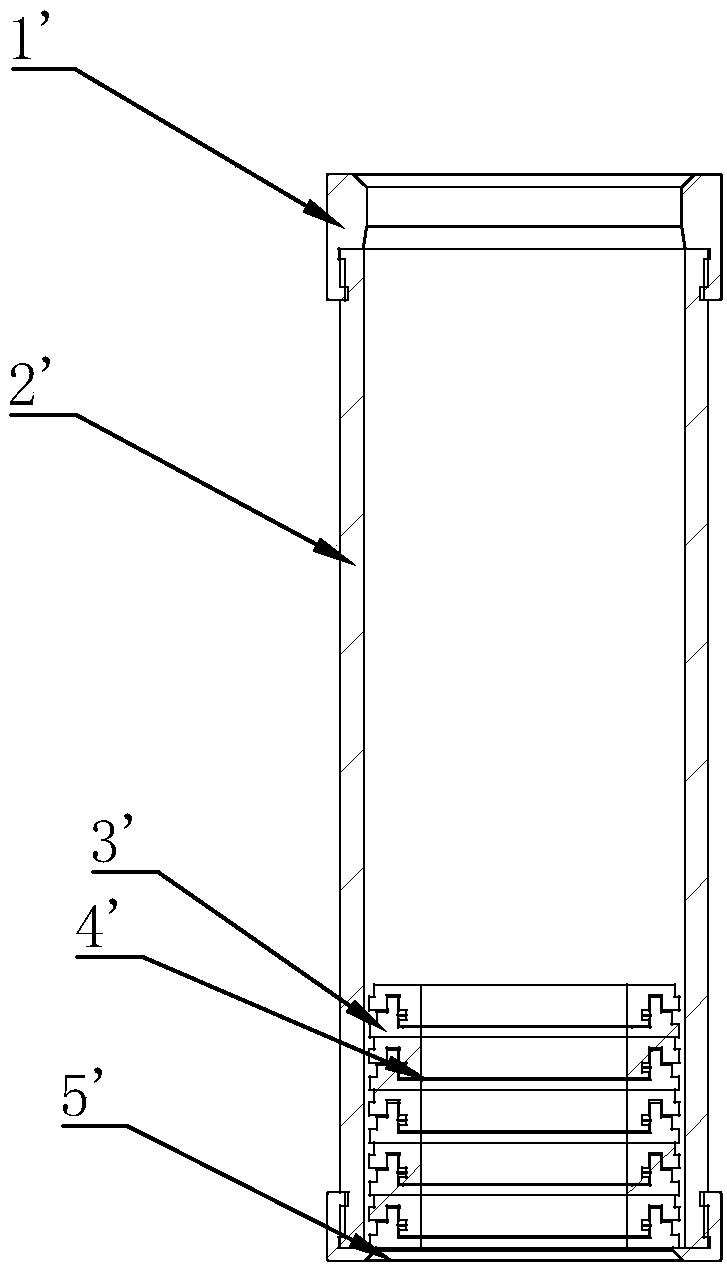

[0036] A filter membrane storage mechanism 3, a first slide mechanism 1, a second slide mechanism 7 and a third slide mechanism 4 are installed in the housing, the filter membrane storage mechanism 3 is fixed on the support platform 2, and the filter membrane storage mechanism 3 includes refrigeration Cavity 302, unsampled filter membrane cartrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com