Water flow velocity and direction sensor

A sensor and water flow technology, applied in the field of sensors, can solve problems such as high failure rate, susceptible signal interference, complex circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

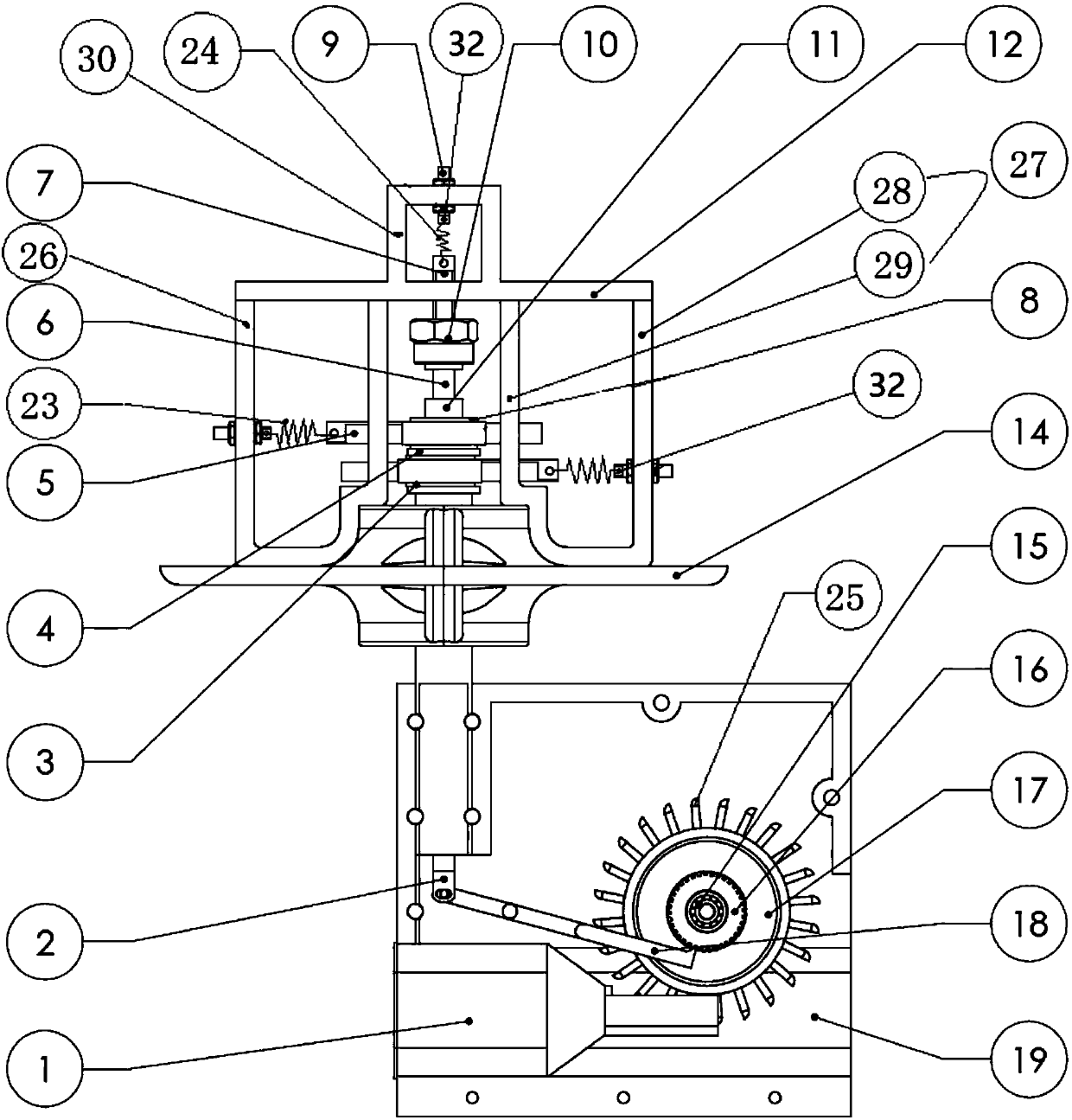

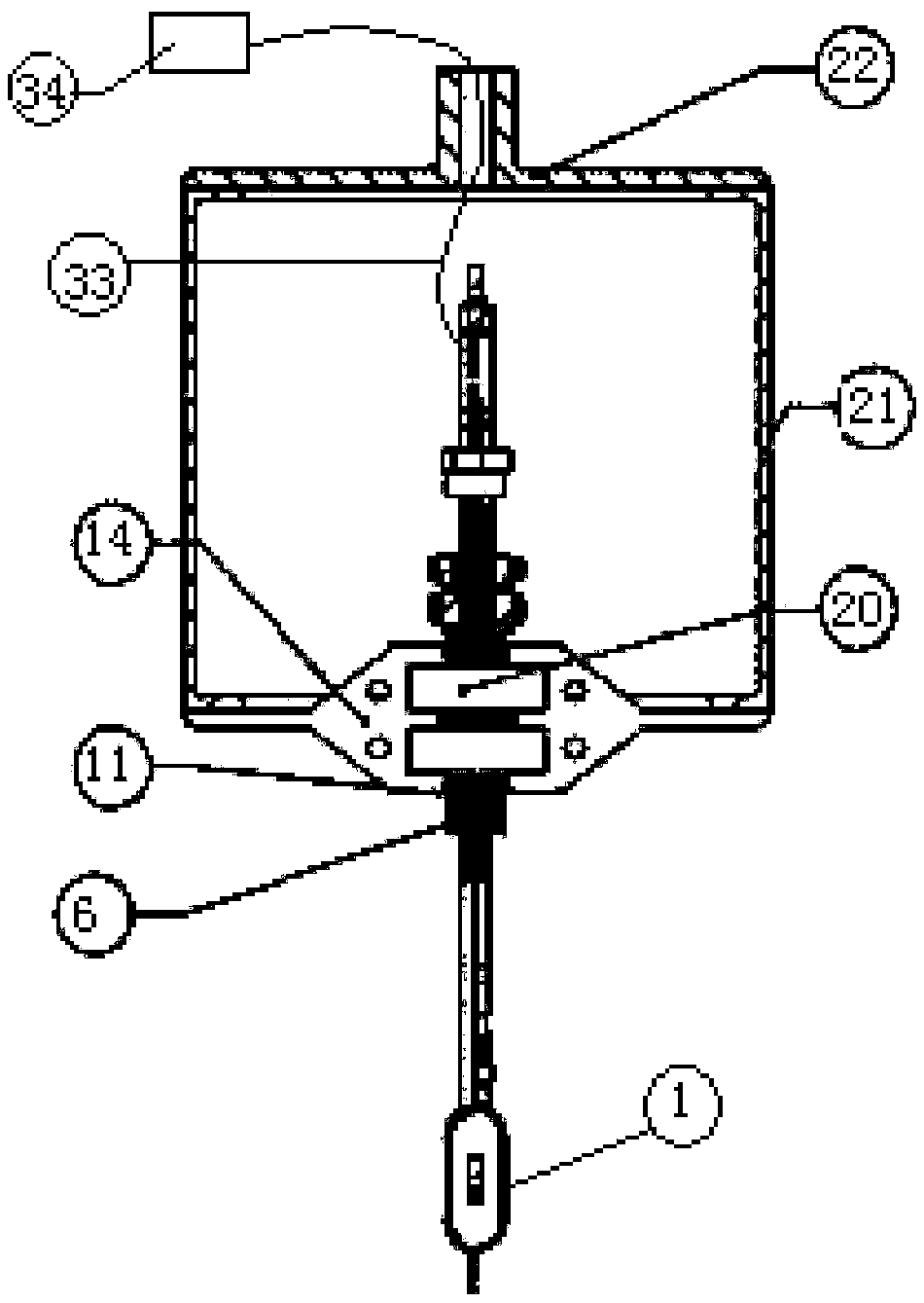

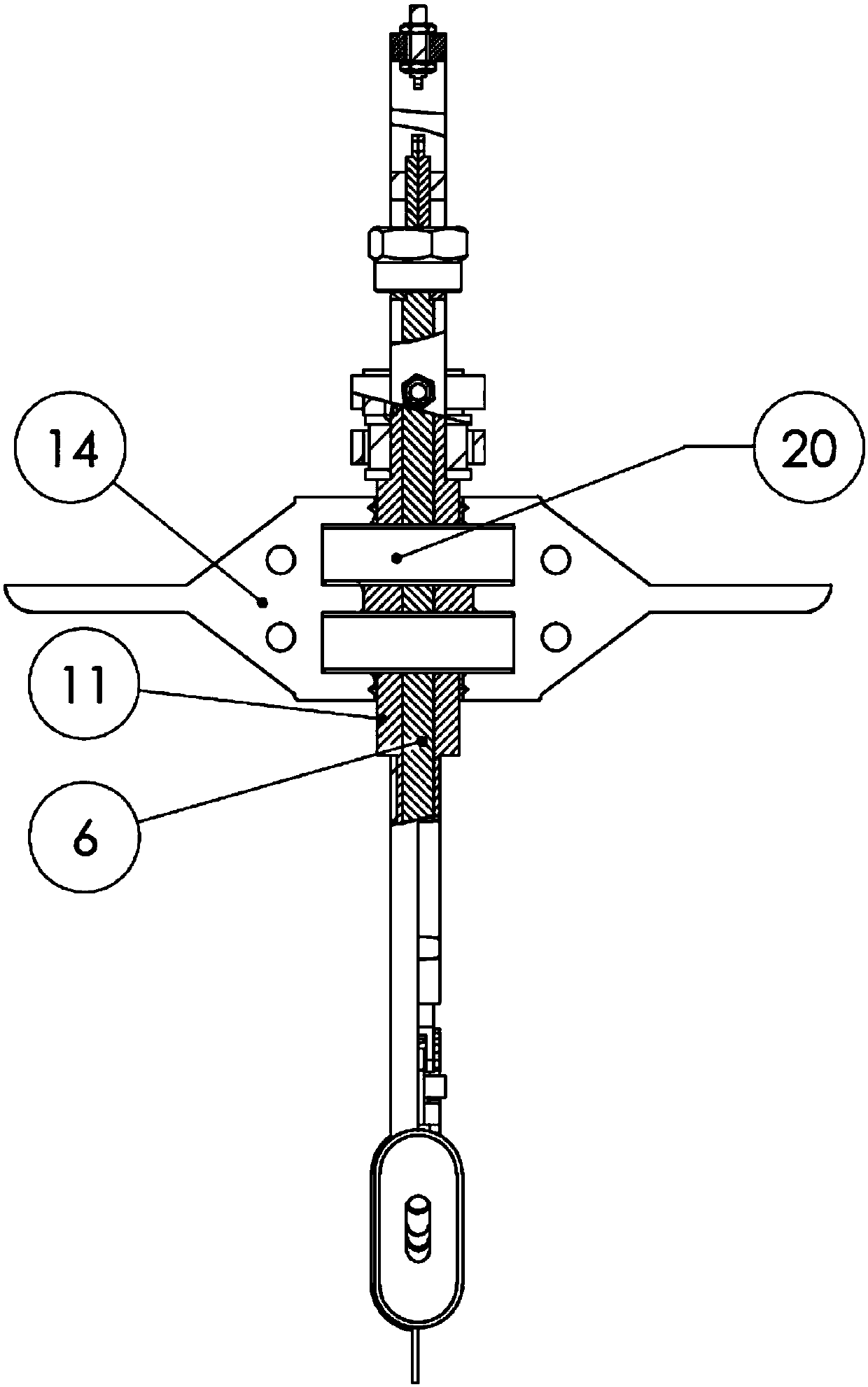

[0029] Furthermore, please also refer to figure 1 , 4 , as a specific embodiment of the water flow velocity sensor provided by the present invention, one side of the universal plate 19 is horizontally provided with a Venturi tube 1, and the large diameter end of the Venturi tube 1 is correspondingly arranged on the steering shaft 11 On one side, the opening of the venturi tube 1 is arranged at the large-diameter end, and the opening faces the outside of the universal plate 19, and several water tanks 25 are arranged at intervals on the rim of the water wheel 17, and the venturi tube 1 The small-diameter end is provided toward the water tank 25 . Water flows in from the large-diameter end of the Venturi tube, passes through the variable diameter of the Venturi tube, and flows out at a relatively high velocity at the small-diameter end. The water tank on the edge of the water wheel drives the water wheel to rotate under the impact of the water flow. The coaxially fixed gear rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com