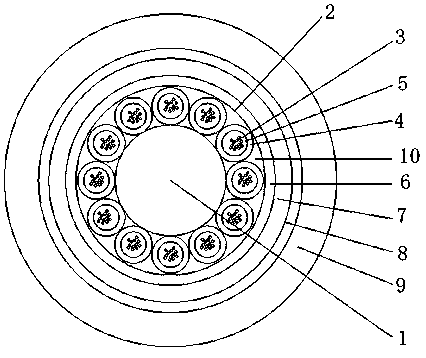

Stranded voltage-resistant optical cable and preparation method thereof

A technology of layer-stranded optical cables, applied in the direction of light guides, optics, optical components, etc., can solve the problems of water seepage in the cable core, slow expansion of water-blocking cable paste, etc., to improve stability, solve the problem of easy aging, and solve the problems of water seepage in the cable core Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

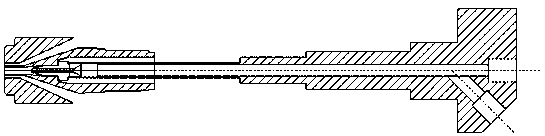

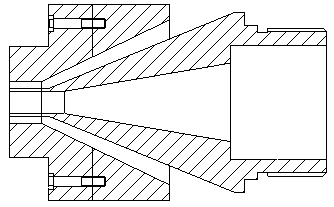

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a layer-stranded pressure-resistant optical cable, comprising the following steps:

[0033] 1) Firstly, select the optical fiber, and select the optical fiber with the required size and performance through the performance inspection of the optical fiber. Set the pay-off tension of the optical fiber as: 80g±10g, set the take-up tension as: 60g±5g, and set the mold For: the inlet mold is 260um and the outlet mold is 254um, to ensure that the diameter of the fiber after coloring is maintained at: 252~260um;

[0034] 2) Then the optical fiber is colored, by setting the curing power of the curing furnace at the actual production speed to 100%, selecting a 10-inch UV lamp with a power of 6000W, and ensuring that the nitrogen pressure in the curing furnace during the production process is ≥ 2.5 m3 / h to ensure The absolute curing degree of colored optical fiber is above 95%;

[0035] 3) Preheat the optical fiber, preheat the optical fiber for 2 hours, th...

Embodiment 1

[0043] A method for preparing a layer-stranded pressure-resistant optical cable. The specific steps are: screening optical fibers, optical fiber coloring, secondary coating of optical fibers, cable forming, inner sheath extrusion, outer sheath extrusion, and finished product inspection.

[0044] Preferably, through the inspection of optical fiber performance, the optical fiber with required size and performance is screened out, and the indicators are as follows.

[0045]

[0046] Preferably, the pay-off tension of the optical fiber is set to 80g±10g, the take-up tension is set to 60g±5g, and the mold is set to: the inlet mold is 260um and the outlet mold is 254um, so as to ensure the diameter of the optical fiber after coloring Maintain at: 252 ~ 260 um, by reducing the diameter of the fiber to achieve the purpose of reducing the duty cycle of the fiber in the loose tube.

[0047] Preferably, by setting the curing power of the curing furnace at the actual production speed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com