Separated type near-field micro-nano photoetching method and device based on white light interferometry gap detection and ultraprecise aligned overlaying technology

An overlay technology, a white light interference technology, is applied in the field of separate near-field micro-nano lithography methods and devices, and can solve the problems of large lateral displacement of the reticle and the substrate, short service life of the reticle, and low alignment accuracy, etc. Achieve the effect of improving service life, improving accuracy, ensuring stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the purpose, technical solution, device and other advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. However, the following embodiments are only limited to explain the present invention, and the protection scope of the present invention should include the entire contents of the claims, and through the following embodiments, those skilled in the art can realize the entire contents of the claims of the present invention.

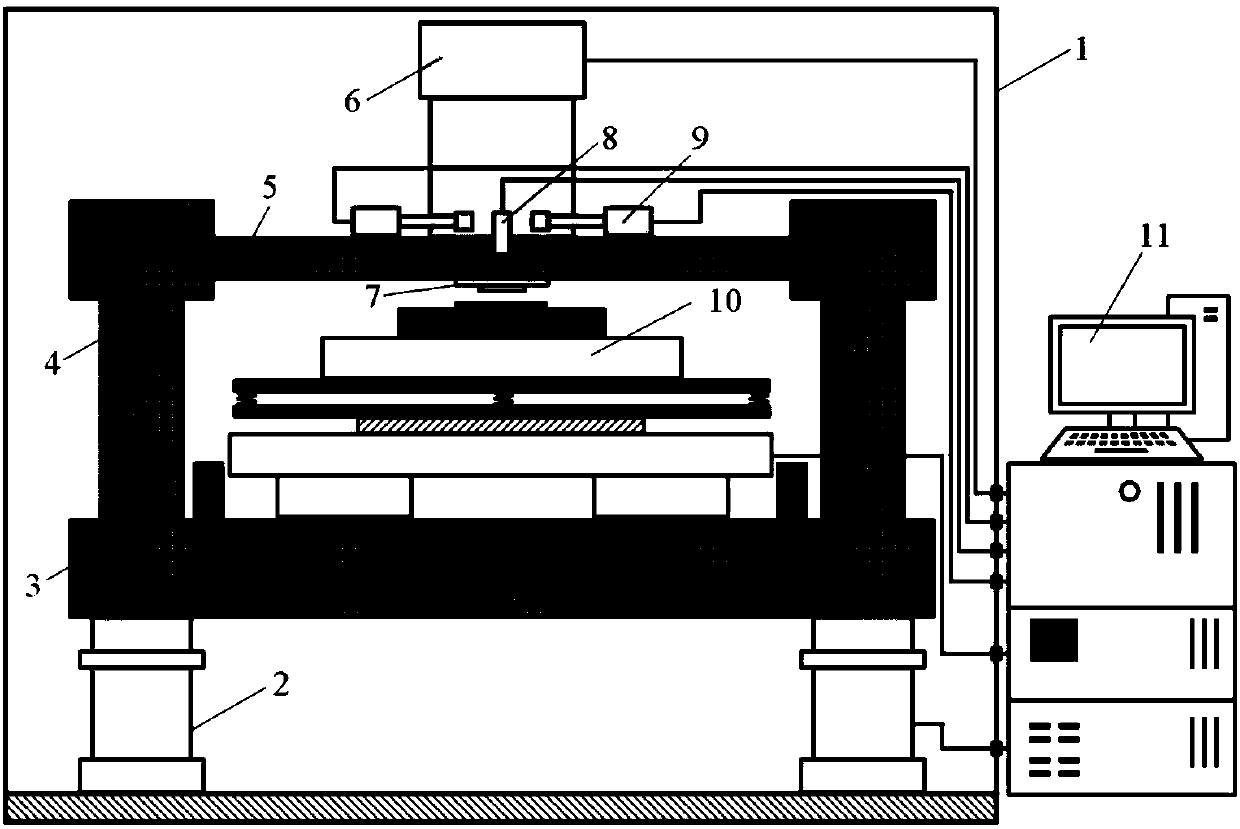

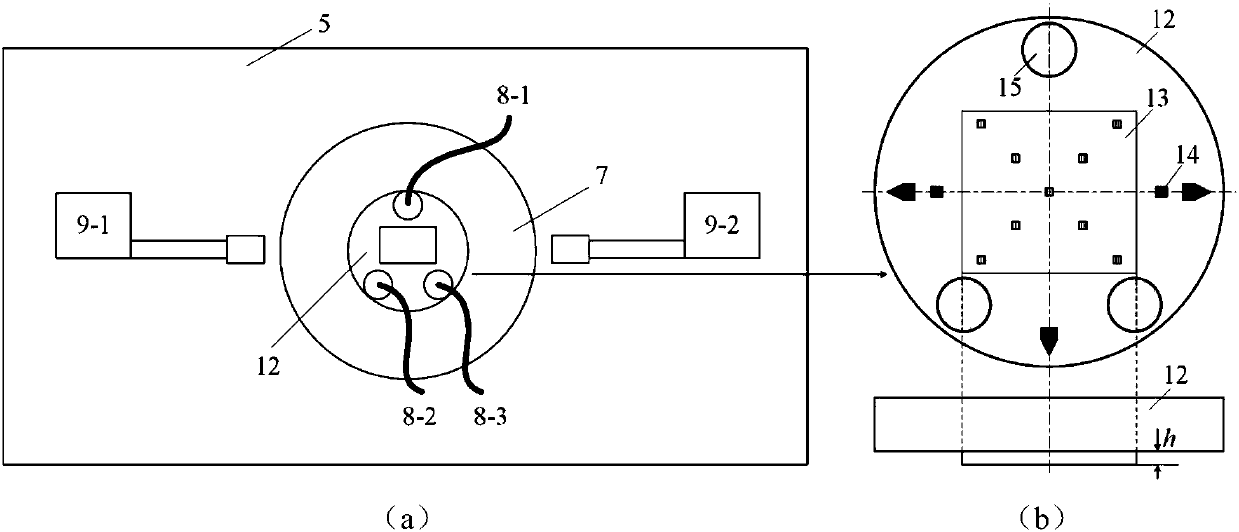

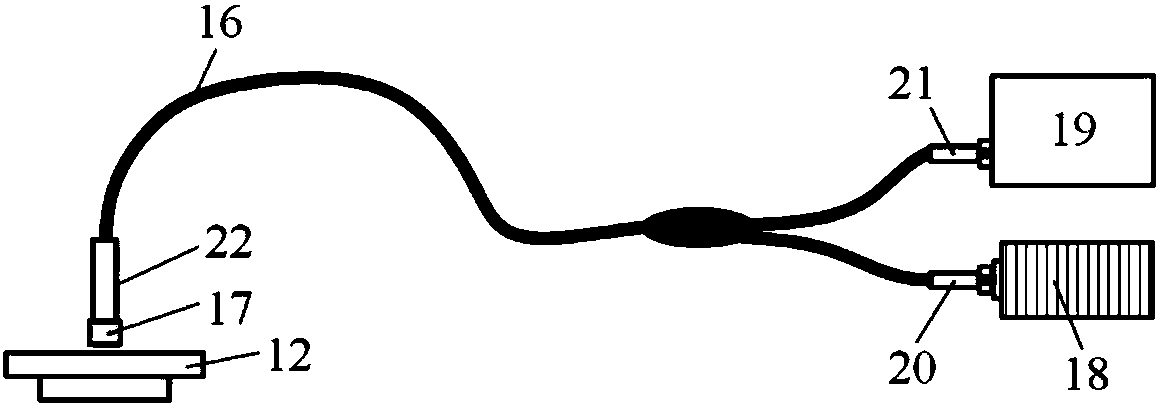

[0059] refer to figure 1 , the separated near-field micro-nano lithography device based on white light interference gap detection and ultra-precision alignment overlay technology consists of an ultra-precision environmental control system 1, an active vibration isolation platform 2, a marble plate 3, a support frame 4, and a main substrate 5 , ultraviolet exposure light source 6, lithography lens module 7, gap detect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com